Introduction

From the viewpoint of management science, managers must rationally allocate the limited resources at the managers’ disposal by making optimal decisions that result in the ultimate outcome of profit maximization. Thus, the content of managerial rationality requirements is to make decisions that maximize an organization’s benefits. Supply chain management (SCM) is a proven strategic business structure that’s goal is to implement organizational decision making that results in optimal performance. It has gained wide acceptance in recent years because it helps managers make optimal decisions that rationally allocate resources that increasing are supplied by a global network of suppliers. In addition, customer demands for variety, quality, delivery, and speed require the supply chain to operate “slicker” as its performance and cost is pivotal to overall profit maximization.

While ideal rational decision making in SCM is an impossibility when viewed as comprehensive rationality, SCM is a collection of decisions made under the constraints of bounded rationality that can approximate optimal decisions. Supply chain management systems are instantiations of management support systems which provide instances of decision technology. They are composed of a set of intelligent decision agents, which interact with other decision agents to plan and execute one or more responsibilities. Decision agents are an “autonomous, goal-oriented software process that operates asynchronously, communicating and coordinating with other agents as needed” (Fox et al., 2000).

Armed with information system facilities, which collect and capture decision predicates to inform a decision choice, as a principal component, decision support systems provide analytic aids, to assist in the managerial decision making process. The employment of which type of decision making aid (represented by a decision support system), in the managerial decision domain is governed by the nature of the decision choices and the predicates that are available to make the decision. A true decision support system extends the bounds of managerial rationality to improve organizational performances. Indeed, it is important to distinguish that decision support systems (DSS), knowledge management systems, and expert systems, concentrate on how IT-enabled systems assist humans in decision making. In recent years, an unique class of agent-based computer constructs called Directive Decision Devices (DDD) has evolved that are computer-centered. A true computer-centered DDD is either designed to displace human decision makers and operate autonomously or they co-exist in control of human functionaries (Sutherland, 2007). DDDs and decision agents are employable in SCM and are based on the type of decisions that an organization faces. Therefore the purpose of this research is to investigate the optimal employment of supply chain management decision agents in relationship to the type of organizational decision making.

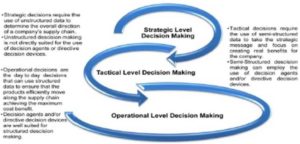

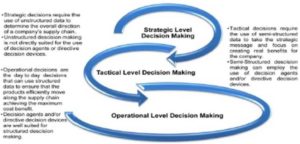

This paper is organized as follows. First, this research discusses SCM and organizational decision making. It then defines the three levels of organizational decision making and the computer-based constructs that can be used in the optimization of supply chain performance. These levels have been identified in the management literature as strategic level (unstructured), tactical (semi-structured), and operational level (structured) decision making(Gorry and Morton, 1971). DDDs and decision agents can be employed in the tactical and operational levels of decision making. Specific instantiations of decision agents and DDDs and their references in the literature will be outlined and a concluding construct is presented.

Supply Chain Management Background

Supply chain management (SCM) is a proven business strategy that’s goal is to implement decision making that results in optimal performance. Supply chains can exist in both manufacturing and service organizations, and they are principally concerned with the flow of products and information between the organizations in the supply chain network, the procurement of materials, transformation of materials into finished products, and distribution of those products to the end customers. Today’s information-driven, integrated supply chains are enabling organizations to reduce inventory and costs, add product value, extend resources, accelerate time to market, and retain customers. In the last few years, organizations that are supply chain innovators have migrated from building excellence in its supply chain to making use of the supply chain to create added-value.

Values can be in the form of new product ideas, innovative processes, market expansion, new ways of serving customers, and new solutions for businesses. In addition, the availability of real-time information and real-time data processing tools, such as radio frequency identification (RFID), GPS, flow control sensors, cellular telephones, navigation systems, and satellite positioning systems has raised new management opportunities and challenges for organizations. Automatic decision technology is available that automates, connects and manages information flows and transactions for specific functions in supply chain optimization (Davenport and Harris, 2005). Therefore to manage cross-functional and cross-enterprise decision making in SCM, this research will group decision making into three categories defined in the management literature: strategic, tactical, and operational (Gorry and Morton, 1971). This will provide a model for understanding SCM decision making and the role of decision agents in SCM and the support that can be offered by computer-based constructs(Mattia, 2010a, Mattia, 2010b).

Strategic Level Decision Making

Strategic decisions are the highest level. The strategic level defines the supply chain network. Thus, this author feels this is the appropriate place to begin a discussion on decision making in supply change management. Here a decision concerns general direction, long term goals, philosophies and values of the supply chain. These are qualitative (judgmental) decision making that include activities such as building relationships with suppliers and customers, and integrating information technology (IT) within the supply chain. These decisions are the least structured and most imaginative; they are the most risky and of the most uncertain outcome, partly because they reach so far into the future and partly because they are of such importance to the supply chain. Traditional “technical” solutions cannot use qualitative decision systems to arrive at optimal solutions, due to the nature of the input data that is available to make these decisions. Qualitative decision making aids use judgmental data, soft predicates that are gathered using interpretive or indirect inputs. “Fuzzy set” conventions are involved in most of the methods for qualitative decision, but occasionally some scenarios can use multi-criteria methodologies (Haleh and Hamidi, 2011). The types of decisions that are made using qualitative methods are those where the possible outcomes are largely unknown, and the input data is tertiary in nature. Most “fuzzy set” approaches devise models in which each decision alternative is quantized, and the higher the utility rating for a given action, the more a decision-makers preferences are satisfied (Siskos et al., 1984). Ordered weighted averaging operators are a new family of operators that provide an aggregation function to satisfy conditions in multi-criteria decision-making (Yager, 1988).

Decision making is typically instigated by the users at the strategic level. Decision making tools at this level have a mission that is advisory, and its employment a conscious choice or decision. The strategic level defines the selection of suppliers, transportation routes, manufacturing facilities, production levels, and warehouse locations in SCM. Decision making at the strategic level may lack precision in data and the empirical inaccessibility of key properties (Sutherland, 1988), therefore subjective decision tools rely heavily on qualitative analysis initiatives. The systems that support this level of decision making are grouped into two types: elicitive, which handle response alternatives that may or may not be grounded in precedent, and structural, which use modern techniques for handling multi-criteria decision making (MCDM) by imposing a “structure” on many subjective and qualitative inputs that involve making choices in the presence of multiple conflicting criteria (Bragge et al., 2010). Although elicitive decision support aids command the majority of the discussion of strategic analytic aids, this research selected two structural initiatives, AHP and ARIADNE. They are two of the most commonly seen multi-criteria decision making methods in managing the supply chain (Subramanian and Ramanathan, 2012).

Analytic Hierarchy Processing (AHP) requires decision makers to judge the relative importance of each criteria and indicate their preference regarding the importance of each alternative criteria. A decision maker does not have to be skilled at formulating goal equations, nor does the decision maker have to be knowledgeable about goals and priorities, thus AHP has an ease-of-use advantage over goal programming and other qualitative decision support systems. A drawback of AHP is that it is often difficult for large groups to objectively rank criteria while keeping each binary comparison in a comparable frame of reference. This stems from the use of the pairwise method used to evaluate alternatives.

Alternative Ranking Interactive Aid based on DomiNance structural information Elicitation (ARIADNE) is a strategic decision-making aid which encourages the search for a behaviorally realistic and rational dominance structure to facilitate the decision-making process. Parameter values in the form of equality and inequality bounds are derived from the decision maker based on the structure of the decision scenario and the steps in the formulation and analysis of the decision process. ARIADNE interprets the information and it arrives as decision alternatives, once these parameters have been elucidated. It is worth noting that a key limitation to ARIADNE is that it relies on a well-trained analyst to elicit the necessary input parameters for the decision scenario and does not concern itself with the formulation and analysis portion of decision support (Sage and White, 1984).

Several examples of strategic analytic decision aids exist in SCM, although many of these systems are very difficult to generalize across differing problem domains.

Min and Melachrinoudis applied the fuzzy analytic hierarchy process (AHP) to aid in the configuration of supply chain networks and assess the viability of the proposed sites from supply chain perspectives (Min and Melachrinoudis, 1999)

Wang, Huang et al. applied the fuzzy analytic hierarchy process (AHP) to aid in supply chain design. The authors relate product characteristics to supply chain strategy and adopt supply chain operations reference (SCOR) model level I performance metrics as the decision criteria for supplier selection. (Wang et al., 2004)

Decision agents and DDDs do not directly support (they would behave poorly if they performed these tasks) the strategic level of decision making in supply chain management. In contrast, they do effectively support the lower levels of decision making (Blue et al., 2006, Sutherland, 2007, Fox et al., 2000), and therefore will be distinguished from the typical DSS at the tactical and operational levels in this paper. Hence, decision agents and DDDs will then to be limited to technically tractable decision situations (Sutherland, 2007, Blue et al., 2006), because they have been proven to behave well, if they performed these types of tasks. Therefore, these situations must fall into one of these four families of facilities in order to be solvable at the tactical and operational levels of decision making.

Tactical Level Decision Making

Tactical decision making supports strategic decisions. The supply chain tactical level is where planning and scheduling is done to meet actual demands. Decision making tends to be medium range, medium significance, with moderate consequences to the supply chain, although it is important to note that a continual mismanagement at this level can greatly impact the strategic level. Probabilistic decision support systems and DDDs can employ statistical inference formulations to arrive at satisfactory (rational and preferably, but not always optimal) solutions. The types of decisions that can be made using probabilistic methods are those where the possible outcomes are only partially enumerated, with the alternatives are different from each other along an axis, rather than different in kind. The decision predicates are empirical (secondary) in nature, with an element of uncertainty in the inputs; however, there is good measurement of the likelihood of error.

Probabilistic decision mechanisms are a mathematical form of inductive inference. Decision theory provides techniques for mathematically evaluating potential outcomes of alternative actions in a given decision situation where there are decisions that are made in uncertainty. The two primary approaches to probabilistic analytic decision making are classical statistical inference and Bayesian-based techniques. Classical statistical inference techniques include sampling, probability distributions, regression and correlation analysis and hypothesis testing.

Examples include payoff matrices and regression trees, which require the decision maker to have an objective desired outcome. Bayesian decision theory recommends maximizing subjective expected utility and places an emphasis on which of the decision alternatives is best according to the decision maker’s preferences. Bayesian decision-based techniques weigh more recent input data more heavily when evaluating alternatives for decision making.

Probabilistic decision making fall into two discrete types. The first type is Categorical/Probabilistic, which is used in forecasting and projection-driven decision making scenarios because it can be handled by comprehensive predictive constructs (classification or regression trees). The second type is Computational/Probabilistic, where decision making information is gathered and extrapolative-projective (statistical inference type) techniques are used to determine optional decisions (Blue et al., 2006). Alternative probabilistic decision techniques can include graphical solutions, such as GRS (generalizable, realizable sets), finding an alternative way of presenting data other than RDBMS. Visual data can also be used as inputs to probabilistic decision making, such as GIS-type mapping for portraying frequency and density distribution data.

Decision agents have emerged in a new software architecture for managing the supply chain at the tactical and operational levels. This architecture views the supply chain as composed of a set of intelligent and autonomous decision agents, where each agent in the supply chain is responsible for one or more activities. In addition, each decision agent interacts with other agents in the planning and execution of their responsibilities (Fox et al., 2000).

An Agent-Based Model (ABM)

An Agent-Based Model (ABM) uses mathematical models, numerical solution techniques and computers (algorithmic form) to analyze and solve decision making problems. Extensive computational resources are needed for simulating the actions and interactions of autonomous individuals in a network. The supply chain is a network composed of a set of intelligent software decision agents, which interact with other decision agents to plan (tactical level) and execute (operational level) one or more responsibilities. Decision agents are an “autonomous, goal-oriented software process that operates asynchronously, communicating and coordinating with other agents as needed” (Fox et al., 2000). The agent based models simulate the simultaneous operations of multiple agents, in an attempt to re-create and predict the actions of complex buyer-seller interaction. It is a process of emergence from a micro level of systems, where individual agents act in their own interest (economic or social status), to a macro level of systems. Decision agents have limited knowledge, but may experience “learning”, adaptation, and reproduction.

Supply chain management systems are instantiations of management support systems which provide instances of decision technology. They are composed of a set of intelligent decision agents, which interact with other decision agents to plan and execute one or more responsibilities. (Fox et al., 2000). Intelligent decision agents are wholly autonomous, carrying out its own agenda, and acting as an agent for no one, while being cable of interacting and communicating with other decision agents. Multi-agent supply chain management systems are composed of distributed agents that do not have the capabilities to achieve an objective alone and thus must communicate.

Today, more sophisticated planning, scheduling, and coordination methods contribute to better decompositions of complex systems, that results in better SCM optimization. Fox, Barbuceanu and Teigen (2000) illustrated a typical agent decomposition for a multi-agent (they have been proven to behave well, when they perform these types of tasks) supply chain system as follows:

- “Order acquisition agent. This agent is responsible for acquiring orders from customers; negotiating with customers about prices, due dates, and the like; and handling customer requests for modifying or cancelling their orders.

- Logistics agent. This agent is responsible for coordinating the plants, suppliers, and distribution centers in the enterprise domain to achieve the best possible results in terms of the goals of the supply chain, including on-time delivery, cost minimization, and so forth. It manages the movement of products or materials across the supply chain from the supplier of raw materials to the customer of finished goods.

- Transportation agent. This agent is responsible for the assignment and scheduling of transportation resources to satisfy interplant movement requests specified by the logistics agent.

- Scheduling agent. This agent is responsible for scheduling and rescheduling activities in the factory, exploring hypothetical “what-if” scenarios for potential new orders, and generating schedules that are sent to the dispatching agent for execution.

- Resource agent. The resource agent merges the functions of inventory management and purchasing. It dynamically manages the availability of resources so that the schedule can be executed.

- Dispatching agent. This agent performs the order release and real-time floor control functions as directed by the scheduling agent.”(Fox et al., 2000)

This research suggests that the longer-term prospects for decision agents with respect to procurement, inventory management and allied activities are very good. Indeed, based on the literature, the next generation of supply chain management system will be distributed, dynamic, intelligent, integrated, responsive, reactive, cooperative, interactive, anytime, complete, reconfigurable, general, adaptable, and backwards compatible.

Examples of tactical decision making in SCM exist in the research literature. Below are two exemplars of probabilistic (statistical) decisions making and the use of decision agents in SCM. In addition, these papers have been chosen because decision agents have been proven to behave well, when they performed these types of tasks.

- “Real-time supply chain control via multi-agent adjustable autonomy” by Lau, Agussurja and Thangarajoo, introduces a model of a supply chain system as a multi-agent system, which is aimed at asynchronous decision making in a changing environment. Thus it allows the overall system to react in real-time. Real-world supply chain problems are used to show that by adjusting an agent’s autonomy in response to changing environment, the behavior of the supply chain system is controlled accordingly. (Lau et al., 2007)

- Weigel and Cao showed how Sears, Roebuck and Company uses a vehicle-routing-and-scheduling system based on a geographic information system to run its delivery and home service fleets more efficiently. They constructed a series of algorithms, including the algorithm to build the origin-and-destination matrix, the algorithm to assign resources, and algorithms to perform sequencing and route improvement. (Weigel and Cao, 1999)

Operational Level Decision Making

Mechanisms at the operational level are used to execute plans and/or by first-level managers to direct specific tasks. These are every day decisions, used to support tactical decision making in SCM. They are structured often made with little thought. Their impact is immediate, short term, short range, and usually low cost. The consequences of a bad operational decision will be minimal, although a series of bad or sloppy operational decisions can cause harm. Operational decision making can be preprogrammed, pre-made, or set out clearly in policy manuals. Consequentially, deterministic decision mechanisms (i.e. decision agents) are frequently used at the operational level and usually employ mathematical techniques to arrive at optimal solutions. Decisions making using deterministic methods are of the type where the possible outcomes and all alternatives are completely enumerated, and the decision predicates are clinical in nature and/or collected from direct measurement, i.e. machine sensor readings.

DDDs effectively support the operational level of decision making in technically tractable decision situations (Sutherland, 2007, Blue et al., 2006). Therefore, these situations must fall into one of these four families of facilities (Table 1), in order to be solvable at the operational level of decision making. Deterministic decision making fall into two discrete types. The first type is Categorical/Deterministic, which is used in simple rule-based decision making scenarios because it can be handled by decision tables and elementary decision. The second type is Computational/Deterministic, where decision making is taken care of by ordinary mathematical optimization and numerical analysis methods (Blue et al., 2006).

Most of these mathematical optimization and numerical analysis are (minimum/maximum) techniques. Examples of these optimization techniques include systems of equations, linear programming, integer programming, goal or multi-objective programming, dynamic programming and queuing models, among others (Rong et al., 2011). An example of an alternative mathematical technique uses a graph (the graphical solution model) to solve a linear programming problem (Martínez et al., 2012). The basic steps in the graphical solution method are: first, plot the model constraints on a set of coordinates in a plane; second, identify the area or volume of the graph that satisfies all the constraints simultaneously (called a feasible solution space). Lastly, an optimal solution is then chosen from within the feasible solution space. Note: graphical deterministic decision support mechanisms use three-dimensional space and are an example of a mathematical optimization technique.

The simplex method, the revised simplex method, the dual simplex method, upper bounding techniques and linear complementary solution techniques, among others are approaches using QSB computational tools that are used to solve linear programming problems. In addition, non-linear programming approaches exist that include separable programming and various decomposition techniques, including Dantzig-Wolfe. Fixed input functions have shifted to dynamic input functions whenever a problem allows. Consequentially, the shift allows Bayesian updating of coefficients and parameters in linear programming (dynamic programming), to give more weight to more recent data increases utility. The shift to real time operational data processing, coupled with Bayesian techniques have allowed for superior operational decision making.

Several examples of operational decision making in SCM exist in the literature. Below are two exemplars of these deterministic (mathematical) employed decision agents. In addition, these papers have been chosen because decision agents have been proven to behave well, when they performed these types of tasks.

- Mark Nissen developed intelligent supply chain agents that represent and autonomously conduct business on behalf of product users, buyers and vendors through an integration of buyer and seller supply chain processes. This work is novel in that it integrates process-level knowledge from operational enterprises with distributed agent technologies. And it makes a contribution by demonstrating how agent-based supply chain integration can be effected along a large-scale, operational, inter-organizational process. (Nissen, 2001)

- Mehdizadeh and Tarokh developed a buyer-supplier coordination model to improve deliveries in a manufacturing supply chain. The proposed model based on the integrated total relevant costs of both buyer and supplier and determines optimal order quantity, the number of deliveries/setups, and quantity of deliveries over a finite planning horizon in a relatively simple JIT (single buyer single supplier) with multiple products scenario and under deterministic conditions. It is shown that the use of JIT purchasing reduces relevant logistics costs for both suppliers and buyers and the optimal delivery policy adopted by both buyer and the optimal delivery policy adopted by both buyer and supplier in a cooperative manner can be economically beneficial to both parties. (Mehdizadeh and Tarokh, 2006)

Strategic, tactical and operational decision making are summarized in Fig. 1 to provide a model for understanding SCM decision making and the role of decision agents and DDDs in SCM and the support that can be offered by computer-based constructs (Mattia, 2010a, Mattia, 2010b).

Fig. 1: Supply Chain Decision Making and the Employment of Decision Agents

A Concluding Multi-Dimensional Construct

The supply chain management instrumental underpinnings tableau for DDDs exemplifies organizational computer-centered agent-based decision making at the tactical and operational levels. Consequentially, the shift of power from humans to computers is shown to be quite effective on technically tractable decision situations. Hence, DDDs are a resource at the managers’ disposal that can automate optimal decision making in SCM that result in the ultimate outcome of profit maximization and have the potential to meet the managerial rationality requirement to make decisions that maximize an organization’s benefits.

All DDDs have the capability for some sort of problem recognition. Thereafter, all need to support response-selection and perform the act or arrange for the act to be implemented.

There appears to be four functional forms in which DDDs, might appear:

- Executory constructs are deployed as stand-alone entities; they are true and complete decision making agents. No human intervention or contribution is needed in the decision situation where a decision table or a neat algorithmic resolution is both available and appropriate.

- Compensatory constructs are deployed as mandatory-access instruments where human capabilities are expectedly deficient or undetermined. Administrative functions, requiring quantitative analysis capabilities are one area that could benefit from compensatory constructs.

- Interdictive constructs are deployed (preferably invisibly) when expectedly harmful decisions maybe enacted. Prevent actions that are harmful, until a higher authority has sanctioned or corroborated it.

- Cooptive constructs are deployed when a human functionary fails to effect a required action or reaction in a timely manner. (Blue et al. 2006)

While decision agents and DDDs have functions (tasks that detail what they can do), and facilities (instruments that carry the means of completing the assignment), each has differing levels of sophistication (capabilities).

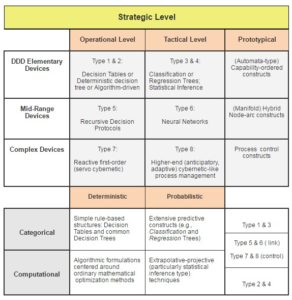

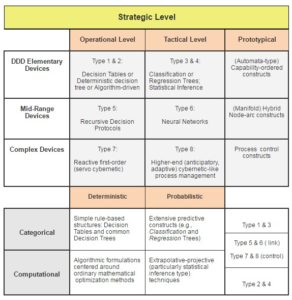

Prototypical Types (Blue et al. 2006)

Type 1: Devices based on Decision Tables or deterministic decision trees which offer simple associative inferences linked with the actions that are needed to perform. They can be used to determine the logic of the device.

Type 2: Deterministic algorithm-driven devices offer the capability to perform efficient inductive inference operations. These devices behave predictably. Given a particular input, they will always produce the same output by passing through the same sequence of states.

Type 3: Devices qua Classification and/or Regression Trees offer the ability to describe the data, resulting in a classification tree, which can be an input for decision making.

Type 4: Statistical inference instrumented devices hold externally-determined values that are drawn from data subject to random variation.

Type 5: Devices designed to execute recursive decision protocols using a deterministic recursive model. It offers one directional causality and hierarchical impacts by correctly classifying members of the population based on several dichotomous dependent variables.

Type 6: Devices qua stochastic node-arc constructs allows for multi-directional causality. They can be used to model complex relationships between inputs and outputs or to find patterns in data without additional exogenous inputs (e.g. neural network constructs).

Type 7: Reactive first order (servo-cybernetic type) control devices make corrections to the system in a direction opposite to the deviation. They are similar to conventional first-order control systems. Corrections are made after-the-fact, using deterministic rectification algorithms.

Type 8: Cybernetic-like process management devices offer an anticipatory function and can control some stochastic processes by being anticipatory and adaptive. These devices use an array of projective values for process variables and can be enacted as necessary.

Therefore based on the behavior of type’s 1 – 8 devices, they are grouped into minimally functional (elementary), compound (mid-range), full featured (complex), categorical, and computational devices. The result is Table 1, which supplies a multi-dimensional view of the instrumental underpinnings for decision agents across decision making levels.

Table 1: A Multi-Dimensional View of the Logic that Informs Agent-Based Decisions

Future Research

This paper represents a first attempt to explore SCM agent-based decision constructs. In particular, the author feels that the employment of decision agents in SCM in relationship to strategic, tactical and operational decision making has not been thoroughly researched. Following this line of inquiry, future research should thoroughly expand and enrich our current model of “how to” best employ the capabilities of decision agents and DDDs in SCM using the defined three levels of organizational decision making. These levels have been identified in the management literature as strategic level (unstructured), tactical (semi-structured), and operational level (structured) decision making (Gorry and Morton, 1971). Specific instantiations of decision agents and DDDs should be validated within the decision making model and the concluding construct. A proposed “optimal” architecture for decision agent based SCM will be introduced based on the validated concluding construct.

In addition, the construct will be explored as related to:

- Agent negotiation, which research has shown leads to optimal solutions in a dynamic and agile supply chain environment (Kim and Cho, 2010, Liu et al., 2011).

- Optimization meta-heuristic, which allows the exchange of information between different optimization problems by means of a pheromone matrix (Silva et al., 2009, Vinay and Sridharan, 2012).

- Closed-loop adaptive supply chain optimization and execution management for value chain adaptability, stability and crisis-resistance (Ivanov et al., 2010, Garcia et al., 2012).

Conclusion

In summary, the issue of interest here is the employment of agent-based decision making in supply chain management. It discusses the sorts of supply-related managerial tasks that decision agents have been assigned, and how well or poorly they could perform these tasks. This research suggests the reasons why organizations might elect to invest supply chain management responsibilities in decision agents and DDDs rather than human functionaries. The suggestions are based on proven managerial and mathematical principles. In fact, this research is organized around these principles. Thirdly, this study generalized a bit by saying something about what the researchers see as the technical reach and limits of decision agents, i.e., in what ways, and to what extent, might they be considered intelligent? Indeed, this research suggests the technical reach of decision agents as reaching as far as the human mind and the instrumental underpinnings can support. Therefore, it is important to remember they are limited to situations that can be mathematical modelled, use numerical solution techniques and computers (algorithmic form) to analyze and solve decision making problems.

This research gives a conclusion about the longer-term prospects for decision agents with respect to procurement, inventory management and allied activities. Indeed, the prospects are very good: the next generation of decision agents will be embedded in systems that will be distributed, dynamic, intelligent, integrated, responsive, reactive, cooperative, interactive, anytime, complete, reconfigurable, general, adaptable, and backwards compatible. Not to mention, common and capable.

An assessment of the current state of agent-based decision making in the area of supply chain management continues to evolve over time (Mattia, 2010a, Mattia, 2010b). Therefore the end contribution of this research is to supply a multi-dimensional view of the instrumental underpinnings that inform decision agents across decision making levels.

Indeed, this research has been a journey through the current decision support systems research literature, viewed in a management framework for a comprehensive, interesting and informative discussion. The results of this research prove that decision agents are powerful and effective decision making mechanisms, but that they are limited to technically tractable decision situations. In addition, the emergence of DDDs, added a separate and interesting computer construct that needed to be investigated and incorporated into the framework for managerial decision making as they become more common and capable.

(adsbygoogle = window.adsbygoogle || []).push({});

References

Blue, J., Andoh-Baidoo, F. & Sutherland, J. W. “Prospects for the Employment of Directive Decision Devices in Financial Applications,” Proceedings of the 39th Hawaii International Conference on System Sciences 2006.

Publisher – Google Scholar

Bragge, J., Korhonen, P., Wallenius, H. & Wallenius, J. (2010). ‘Bibliometric Analysis of Multiple Criteria Decision Making/Multiattribute Utility Theory Multiple Criteria Decision Making for Sustainable Energy and Transportation Systems,’ In: Ehrgott, M., Naujoks, B., Stewart, T. J. & Wallenius, J. (eds.). Springer Berlin Heidelberg.

Davenport, T. H. & Harris, J. G. (2005). “Automated Decision Making Comes of Age: After Decades of Anticipation, the Promise of Automated Decision-Making Systems is Finally Becoming a Reality in a Variety of Industries,” MIT Sloan Management Review 46, p83(7).

Publisher – Google Scholar – British Library Direct

Fox, M. S., Barbuceanu, M. & Teigen, R. (2000). “Agent-Oriented Supply-Chain Management,” International Journal of Flexible Manufacturing Systems, 12, 165.

Publisher – Google Scholar – British Library Direct

Garcia, C. A., Ibeas, A., Herrera, J. & Vilanova, R. (2012). “Inventory Control for the Supply Chain: An Adaptive Control Approach Based on the Identification of the Lead-Time,” Omega, 40, 314-327.

Publisher – Google Scholar

Gorry, G. A. & Morton, M. S. S. (1971). “A Framework for Management Information Systems,” Sloan Management Review (pre-1986), 13, 55.

Publisher – Google Scholar

Haleh, H. & Hamidi, A. (2011). “A Fuzzy MCDM Model for Allocating Orders to Suppliers in a Supply Chain Under Uncertainty over a Multi-Period Time Horizon,” Expert Systems with Applications, 38, 9076-9083.

Publisher – Google Scholar

Ivanov, D., Sokolov, B. & Kaeschel, J. (2010). “A Multi-Structural Framework for Adaptive Supply Chain Planning and Operations Control with Structure Dynamics Considerations,” European Journal of Operational Research, 200, 409-420.

Publisher – Google Scholar

Kim, H. S. & Cho, J. H. (2010). “Supply Chain Formation Using Agent Negotiation,” Decision Support Systems, 49, 77-90.

Publisher – Google Scholar

Lau, H. C., Agussurja, L. & Thangarajoo, R. (2007). Real-Time Supply Chain Control via Multi-Agent Adjustable Autonomy,” Computers & Operations Research, In Press, Corrected Proof.

Publisher – Google Scholar

Liu, Q., Sun, S. X., Wang, H. & Zhao, J. (2011). “A Multi-Agent Based System for E-Procurement Exception Management,” Knowledge-Based Systems, 24, 49-57.

Publisher – Google Scholar

Martínez, L. B., Márquez, A. C., Gunckel, P. V. & Andreani, A. A. (2012). “The Graphical Analysis for Maintenance Management Method: A Quantitative Graphical Analysis to Support Maintenance Management Decision Making,” Quality and Reliability Engineering International, n/a-n/a.

Publisher – Google Scholar

Mattia, A. “The Optimal Employment of Supply Chain Management Decision Support Agents: An Exploratory Study,” 16th Americas Conference on Information Systems, 2010a Lima, Peru.

Publisher – Google Scholar

Mattia, A. (2010b). ‘The Strategic Employment of Decision Agents in Supply Chain Management: An Exploratory Study,’ Southeast Decision Science Institute. Wilmington, NC

Mehdizadeh, E. & Tarokh, M. J. “An Integrated JIT Inventory Model for Supply Chain Management: Single Supplier-Single Buyer with Multiple Products,” Service Operations and Logistics, and Informatics, 2006. SOLI ’06. IEEE International Conference on, 2006. 288-293.

Publisher – Google Scholar

Min, H. & Melachrinoudis, E. (1999). “The Relocation of a Hybrid Manufacturing/Distribution Facility from Supply Chain Perspectives: A Case Study,” Omega, 27, 75-85.

Publisher – Google Scholar – British Library Direct

Nissen, M. E. (2001). “Agent-Based Supply Chain Integration,” Information Technology and Management, 2, 289-312.

Publisher – Google Scholar

Rong, A., Akkerman, R. & Grunow, M. (2011). “An Optimization Approach for Managing Fresh Food Quality Throughout the Supply Chain,” International Journal of Production Economics, 131, 421-429.

Publisher – Google Scholar

Sage, A. P. & White, C. C. (1984). “ARIADNE: A Knowledge-Based Interactive System for Planning and Decision Support,” IEEE Trans. Syst., Man, Cybern, 14.

Publisher – Google Scholar

Silva, C. A., Sousa, J. M. C., Runkler, T. A. & Sá Da Costa, J. M. G. (2009). “Distributed Supply Chain Management Using Ant Colony Optimization,” European Journal of Operational Research, 199, 349-358.

Publisher – Google Scholar

Siskos, J., Lochard, J. & Lombard, J. (1984). ‘A Multicriteria Decision-Making Methodology under Fuzziness: Application to the Evaluation of Radiological Protection in Nuclear Power Plants,’ TIMS/Studies in the Management Sciences, 20, 261-283.

Google Scholar

Subramanian, N. & Ramanathan, R. (2012). “A Review of Applications of Analytic Hierarchy Process in operations management,” International Journal of Production Economics, 138, 215-241.

Publisher – Google Scholar

Sutherland, J. W. (1988). “Prospects for Logical (versus data) Processing Facilities as Strategic Decision Aids,” IEEE Transactions on Systems, Man and Cybernetics, 18, 885-898.

Publisher – Google Scholar

Sutherland, J. W. (2007). ‘Directive Decision Devices: Reversing the Locus of Authority in Human-Computer Associations,’ Department of Information Systems, Virginia Commonwealth University.

Vinay, V. P. & Sridharan, R. (2012). “Development and Analysis of Heuristic Algorithms for a Two–Stage Supply Chain Allocation Problem with a Fixed Transportation Cost,” International Journal of Services and Operations Management, 12, 244-268.

Publisher – Google Scholar

Wang, G., Huang, S. H. & Dismukes, J. P. (2004). “Product-Driven Supply Chain Selection Using Integrated Multi-Criteria Decision-Making Methodology,” International Journal of Production Economics, 91, 1-15.

Publisher – Google Scholar

Weigel, D. & Cao, B. (1999). “Applying GIS and OR Techniques to Solve Sears Technician-Dispatching and Home Delivery Problems,” Interfaces, 29.

Publisher

Yager, R. R. (1988). “On Ordered Weighted Averaging Aggregation Operators in Multicriteria Decisionmaking,” IEEE Transactions on Systems, Man and Cybernetics, 18, 183-190.

Publisher – Google Scholar