[1] Kaensup, W., Wongwises, S. & Chutima, S. (1998). “Drying of Pepper Seeds Using a Combined Microwave/Fluidized Bed Dryer,” Drying Technology: An International Journal 16, 853-862.Publisher – Google Scholar

[2] Vega-Galvez, A., Lemus-Mondacs, R., Bilbao-Sailnz, C., Fito, P. & Andres, A. (2008). “Effect of Air Drying Temperature on the Quality of Rehydrated Dried red Bell Pepper (var. Lumuyo),” Journal of Food Engineering 85, 42-50.

Publisher – Google Scholar

[3] A. S. A. (2010). ‘Annulaire des Statiques Agricoles. République Tunisienne Ministère de l’Agriculture, de l’Environnement et des Ressources Hydrauliques,’Tunisie, Novembre 2010.

[4] Kavak Akpinar, E. & Bicer, Y. (2008). “Mathematical Modelling of Thin Layer Drying Process of Long Green Pepper in Solar Dryer and under Open Sun,” Energy Conversion and Management 49 ; 1367—1375.

Publisher – Google Scholar

[5] Tunde-Akintunde, T. Y., Afolabi, T. J. & Akintunde, B. O. (2005). “Influence of Drying Methods on Drying of Bell-Pepper (Capsicum Annuum),” Journal of Food Engineering 68; 439-442.

Publisher – Google Scholar

[6] Doymaz, I. & Pala, M. (2002). “Hot-air Drying Characteristics of Red Pepper,” Journal of Food Engineering 55, 331-335.

Publisher – Google Scholar

[7] Ergüneş, G. & Tarhan, S. (2006). “Color Retention of Red Peppers by Chemical Pretreatments during Greenhouse and Open Sun Drying,” Journal of Food Engineering 76, 446-452.

Publisher – Google Scholar

[8] Tunde-Akintunde, T. Y. (2011). “Mathematical Modeling of Sun and Solar Drying of Chilli Pepper,” Renewable Energy 36, 2139-2145.

Publisher – Google Scholar

[9] Arslan, D. & Özcan, M. M. (2011). “Dehydration of Red Bell-Pepper (Capsicum Annuum L.): Change in Drying Behavior, Colour and Antioxidant Content,” Food and Bioproducts Processing 89, 504-513.

Publisher – Google Scholar

[10] Belessiotis, V. & Delyannis, E. (2011). “Solar Drying,” Solar Energy 85, 1665-1691.

Publisher – Google Scholar

[11] Farhat, A., Kooli, S., Kerkeni , C., Maalej, M., Fadhel, A. & Belghith, A. (2004). “Validation of a Pepper Drying Model in a Polyethylene Tunnel Greenhouse,” International Journal of Thermal Sciences 43, 53-58.

Publisher – Google Scholar

[12] Passamia, V. & Saravia, L. (1997a). “Relationship between a Solar Drying Model of Red Pepper and the Kinetics of Pure Water Evaporation (I),” Drying Technology: An International Journal 15, 1419-1432.

Publisher – Google Scholar

[13] Passamia, V. & Saravia, L. (1997b). “Relationship between a Solar Drying Model of Red Pepper and the Kinetics of Pure Water Evaporation (II),” Drying Technology: An International Journal 15, 1433-1445.

Publisher – Google Scholar

[14] Sacilik, K., Keskin, R. & Elicin, A. K. (2006). “Mathematical Modeling of Solar Tunnel Drying of Thin Layer Organic Tomato,” Journal of Food Engineering 73, 231-238.

Publisher – Google Scholar

[15] Rathore, N. S. & Panwar, N. L. (2010). “Experimental Studies on Hemi Cylindrical Walk—In Type Solar Tunnel Dryer for Grape Drying,” Applied Energy 87, 2764-2767.

Publisher – Google Scholar

[16] Kooli, S., Fadhel, A., Farhat, A. & Belghith, A. (2007). “Drying of Red Pepper in Open Sun and Greenhouse Conditions: Mathematical Modelling and Experimental Validation,” Journal of Food Engineering 55, 1094-1103.

Publisher – Google Scholar

[17] Kaewkiew, J., Nabnean, S. & Janjai, S. (2012). “Investigation of the Performance of a Large-Scale Greenhouse Type Solar Dryer for Drying Chilli in Thailand,” Procedia Engineering 32, 433—439.

Publisher – Google Scholar

[18] ToÄrul, ĺ. T. & Pehlivan, D. (2004). “Modelling of Thin Layer Drying Kinetics of Some Fruits under Open-Air Sun Drying Process,” Journal of Food Engineering 65, 413-425.

Publisher – Google Scholar

[19] Kaymak-Ertekin, F. (2002). “Drying and Rehydrating Kinetics of Green and Red Peppers,” Journal of Food Science 67, 168-175.

Publisher – Google Scholar

[20] Akpinar, E. K. (2010). “Drying of Mint Leaves in a Solar Dryer and under Open Sun: Modelling, Performance Analyses,” Energy Conversion and Management 51, 2407—2418.

Publisher – Google Scholar

[21] Gűnhan, T., Demir, V., Hancioglu, E. & Hepbasli, A. (2005). “Mathematical Modelling of Drying of Bay Leaves,”Energy Conversion and Management 46, 1667—1679.

Publisher – Google Scholar

[22] Menges, H. O. & Ertekin, C. (2006). “Thin Layer Drying Model for Treated and Untreated Stanley Plums,” Energy Conversion and Management 47, 2337—2348.

Publisher – Google Scholar

[23] Mujumdar, A. S. (1987). Handbook of Industrial Drying, New York: Marcel Dekker.

Publisher – Google Scholar

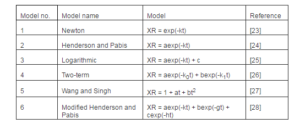

[24] Henderson, S. M. & Pabis, S. (1961). ‘Grain Drying Theory. II. Temperature Effects on Drying Coefficients,’ Journal of Agricultural Engineering Research 6, 169-174.

[25] Singh, S., Sharma, R., Bawa, A. S. & Saxena, D. C. (2008). “Drying and Rehydration Characteristics of Water Chestnut (Trapanatans) as a Function of Drying Air Temperature,” Journal of Food Engineering 87, 213-221.

Publisher – Google Scholar

[26] Henderson, S. M. (1974). “Progress in Developing the Thin Layer Drying Equation,” Transactions of the America Society Agricultural Engineering 17, 1167—1172.

Publisher – Google Scholar

[27] Wang, C. & Singh, R. A. (1978). ‘A Single Layer Drying Equation for Rough Rice,’ ASAE Paper 78-3001. St. Joseph (MI): America Society Agricultural Engineering.

Google Scholar

[28] Karathanos, V. T. (1999). “Determination of Water Content of Dried Fruits by Drying Kinetics,” Journal of Food Engineering 39, 337—344.

Publisher – Google Scholar

[29] Dissa, A. O., Bathiebo, D. J., Desmorieux, H., Coulibaly, O. & Koulidiati, J. (2011). “Experimental Characterisation and Modelling of Thin Layer Direct Solar Drying of Amelie and Brooks Mangoes,” Energy 36, 2517-2527.

Publisher – Google Scholar