Introduction

The world primary energy demand, reported as 505 quadrillion BTU in 2008, is expected to increase by 53% in 2035 (IEO, 2011). Energy security and environmental sustainability are the major emerging issues in the world that can only be addressed through the diversification in the energy resources and clean fuels. The promotion of indigenous renewable energy sources and the low carbon fuels could be a win-win solution while addressing issues of the global warming and climate change. Kyoto Protocol, legally binding EU 20-20-20 targets, and volatility of oil prices have encouraged the global community to reduce the dependence on oil and replace it with a clean and renewable energy resources (Deutmeyer et al., 2012). Biomass energy — a renewable energy — could be a good candidate for replacement of fossil fuels. It can be used in three forms, such as solid (briquette, pellet, char), liquid (ethanol, biodiesel), and gaseous (producer gas, biogas) (Koh and Hoi, 2003).

A blanket use of any type of biomass may not be good for a sustainable source. For example, the rapid increase in food-based fuel has strained the food supplies in some countries. Lignocellulose biomass on the other hand free from this problem is an alternative source of bioenergy. The use of lignocellulosic biomass has increased significantly in producing bio-oil and synthetics chemicals. The lignocellulosic biomass, in spite of all its positive attributes, is associated with the different shortcomings like structural heterogeneity, non-uniform physical properties, low energy density, hygroscopic nature, and low bulk density. These limitations create difficulties in transportation, handling, storage, and conversion processes (Arias et al., 2008; Phanphanich and Mani, 2011; Medic et al., 2011; Uemura et al., 2011; Wannapeera et al., 2011). These properties limit the use of biomass to replace fossil fuels for energy production. Therefore, biomass needs to be pretreated before it can be used in any thermochemical conversions processes. Torrefaction is emerging as such pretreatment method that removes many of the above limitations associated with raw biomass.

This paper presents a comprehensive review of biomass torrefaction. Starting with an introduction in the first section, and an overview of biomass properties is presented in section 2. A detailed review of dry torrefaction is presented in section 3. The effect of torrefaction in different conversion process is discussed in section 4. The explosivity of torrefied biomass, commercial development, potential application of torrefied biomass, and a sustainability approach on torrefaction technology are presented in subsequent sections. Finally, conclusions are presented in section 9.

Overview of Biomass

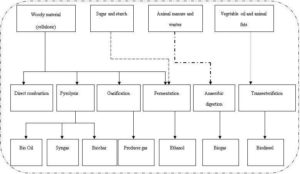

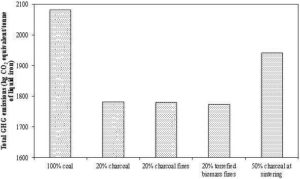

Biomass is any organic materials derived from plants or animals, excluding materials that take millions of years to produce such as: coal or petroleum (Basu, 2010). The energy produced from biomass does not contribute acid rain gases due to the negligible sulfur, and nitrogen contents of biomass (Demirbas, 2008). Biomass stores sun’s energy through photosynthesis process. Human being extracts the stored energy with the help of different conversions routes as shown in Fig. 1. It is noted that biomass can be used directly for energy conversion or upgraded into superior energy carriers such as bio-char, producer gas, and bio-oil through different routes like pyrolysis, gasification, fermentation, transesterification, and anaerobic digestion.

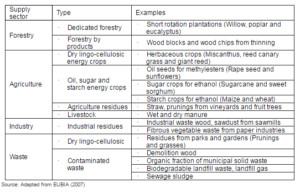

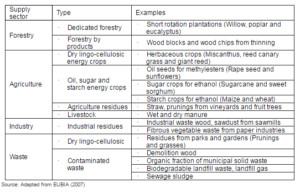

According to the Energy Statistics of International Energy Agency 2009, biomass energy contributed around 10% of the world’s total primary energy supply (IEA, 2009). Biomass can be used as a feedstock for liquid or a gaseous fuel for the transport sector through thermochemical and biological routes, and is therefore considered as a promising renewable energy resource (Demirbas, 2008). Table 1 presents a classification of biomass types by their sources. Forestry and agriculture sector are two main resources as the primary source of biomass. Industry and waste are the secondary sources, as these are derived from biomass from primary source.

Traditional use of biomass has been limited to cooking and heating purpose, which has caused adverse impacts such as land degradation and desertification. However, modern use of biomass — a high quality energy carrier converted from raw biomass — for electricity, and heat production can substantially reduce emissions from the conventional power plants (Hoogwijk et al., 2005). This ability to convert raw biomass into convenient energy carriers increases the interest on biomass use for energy purpose, especially the lignocellulosic biomass.

Figure 1: Biomass Energy Conversion Routes

Table 1: General Classification of Biomass Resources

The Structure of the Lignocellulosic Biomass

Biomass can be lignocellulosic or non-lignocellulosic materials. The lignocellulosic material is the non-starch and fibrous part of the plants that consists mainly of cellulose, hemicellulose, and lignin (Basu, 2010). The non-lignocellulosic material, on the other hand, is non-cellulosic organic material, which is used mainly for nutritional purpose. Sugar, starch, protein, and fat content of any crops are the non-lignocellulosic materials. These materials can be easily hydrolyzed to produce upgraded bioethanol (Doelle, 2012.).

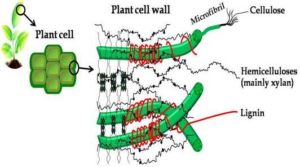

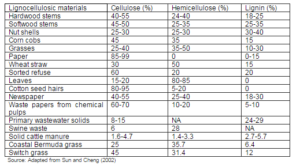

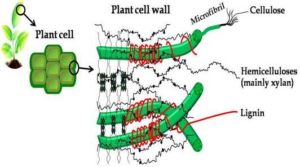

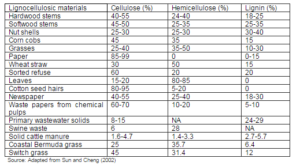

An efficient conversion of lignocellulosic biomass needs better understanding of the cell wall structure and their compositions. Plant’s cell wall, which consists of four major macro components namely primary wall, secondary wall, plasma membrane, and middle lamella, are made of cellulose, hemicellulose, lignin, and some extractives as shown in Fig. 2. Such plants are referred as the lignocellulosic material (Foster et al., 2010). These polymers give a rigid structure to the plant. Table 2 presents a comparison of range of these polymer constituents for some principal types of lignocellulosic materials. Here we note that biomass from animal waste is rather poor in these three polymers. As such their classification under lingo-cellulose, biomass is questionable. A brief introduction to the polymeric constituents of the plant cell is presented here.

Lignin

Lignin is a three-dimensional polymer made up of predominantly C-O-C and C-C linkages (Rowell, 2005). Lignin could be of different types such as: (i) lignin of hardwood (angiosperms); (ii) lignin of softwood (gymnosperms); and (iii) lignin of grasses (non-woody or herbaceous crops) (Buranov and Mazza, 2008).

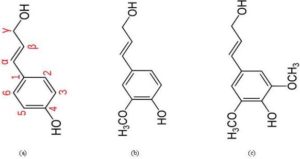

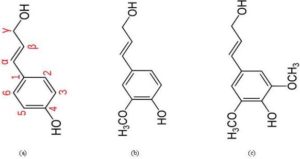

Lignin is the generic term for a large group of aromatic polymers (Vanholme et al., 2010), Lignin is a co-polymer of three phenyl propane monomer units (monolignols) such as para-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol (Fig. 3). β-O-4-aryl ether bonds are the most common coupling linkages in the polymerization process of lignin monomers (Pandey and Kim, 2011). Lignin thermally decomposes over a broad temperature range, because various oxygen functional groups from its structure have different thermal stabilities, their scission occurring at different temperatures (Brebu and Vasile, 2009). The lignin is thermally stable over a wide temperature range from 100 °C to 900 °C (Yang et al., 2007). Thus, in the torrefaction process, lignin remains less modified and a biomass with higher lignin content yields more solid products.

Cellulose

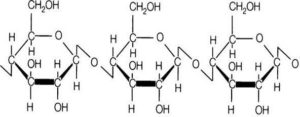

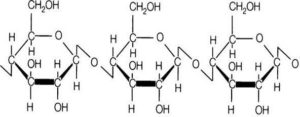

Cellulose is a long chain polymer of glucose that can establish intra-molecular and inter-molecular hydrogen bonds. Cellulose (C6H10O5)n is characterized by its large molecular weights of 500,000 units monomers (Basu, 2010). D-glucoses are the major constituents of cellulose, which are linked by β-(1→ 4)-glucosidic bonds (Rowell, 2005). The structure of the cellulose is crystalline in nature that has higher packing density that helps to increase the strength of biomass structure. Figure 4 shows the typical chemical structure of cellulose, showing different hydroxyl groups in the chain. The hydroxyl group increases its ability of forming hydrogen bonds that is responsible for hygroscopic behavior of raw biomass. The hygroscopic nature of cellulose increases the gap between cellulose chains, resulting in the swelling of biomass. Thus, during the thermal treatment period, the solid product undergoes the shrinkage phenomena, causing dimensional variations.

Hemicellulose

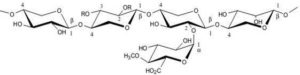

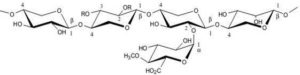

Hemicelluloses are composed mainly of heteropolysaccharides such as hexoses (glucose, mannose, and galactose) and pentoses (xylose and arabinose) (Pollex et al., 2012). Hemicelluloses are polysaccharides of plant’s walls, which strengthen the primary cell walls. Xyloglucans, xylans, mannans, glucomannans and β-(1→3, 1→4) — glucans are important constituents in the hemicellulose (Scheller and Ulvskov, 2010). It has random amorphous structure, and is the weakest constituent of biomass cells (Basu, 2010). Hemicellulose is made predominantly of acetyl- and methyl- substituted groups (Rowell, 2005). These groups are responsible for releasing light volatiles gases such as CO2 and CO, upon low temperature thermal pretreatment. Hemicellulose, which has a lower degree of polymerization compared to cellulose, undergoes to substantial thermal degradation, and has significant effect on mass yield in the torrefaction process. Figure 5 shows the structure of hemicellulose in a hardwood.

Biomass for Energy Generation

With the growing energy demand and emerging environmental issues, the new and clean energy sources are being explored to avoid possible damages from global warming and climate change. Biomass is widely distributed around the world, and it is often available at relatively low price. It could therefore become the world’s important renewable energy resource. Biomass can help replace the fossil fuels in transportation, and the power generation sector because it has the ability of producing biofuels such as biodiesel, methanol, and hydrogen through the Fisher-Tropsch Synthesis process (Ptasinski, 2008). However, some of its inherent limitations like low energy density, fibrous nature, and hygroscopic nature, use of biomass for energy generation have so far been restricted. Currently, co-firing technology has gained wide acceptance for reducing fossil fuel consumption and corresponding emission in thermal power plants by replacing a part of fossil fuel with biomass. But the share of biomass in the mix has been limited to 5-10%. A higher percentage is not economically feasible unless the properties of biomass are upgraded.

Shortcomings of Biomass as Energy Source

Despite all its advantages, biomass has some shortcomings that often create difficulties in its wide scale use as an energy source. Compared to other fuels like coal, biomass has higher oxygen content, lower calorific value, lower bulk density, higher hygroscopic nature, and higher moisture content. Thus, biomass faces some technical challenges in energy conversion systems (van der Stelt et al., 2011).

The low bulk density of raw biomass causes storage and handling problems. It also reduces the energy density of biomass that in turn increases the volume of biomass feed into a conversion system to produce a given amount of power. The low bulk density of biomass also increases the cost associated with storage, transportation, and handling of materials at the conversion plant (Arias et al., 2008; Tumuluru et al., 2011).

The higher oxygen content reduces the heating value and thereby makes it a lower-grade fuel. The higher oxygen content is responsible for producing a large volume of the flue gas during combustion (van der Stelt et al., 2011) that requires much bigger size of plants and auxiliary equipment.

The higher moisture content (45-60%) of raw biomass has significant negative impact on the bioenergy production and its consumption chain (Ratte et al., 2011). Though, moisture adds some benefits in biological conversion methods, it remains as one of the major obstacles for thermochemical conversion. A modest amount of moisture, however, shows some benefits in the gasification process in which the steam produced from the moisture assists in increasing the hydrogen concentration in the producer gas (Acharjee et al., 2011). At the same time, higher moisture also decreases the overall gasification temperature, resulting in a lower gasification efficiency and higher tar formation. Moist biomass on the other hand also shows a greater tendency to undergo the natural decomposition. This alters the physical, chemical, and microbiological properties and degrades the fuel quality (Tumuluru et al., 2011). A wet biomass, when stored could lose some solid mass due to the microbial decaying process (Medic et al., 2011).

Figure 2: Structure of Primary Cell Wall of Plant Cell

Source: Adapted from Tomme et al. (1995)

Table 2: Polymeric Constituents of Different Biomass Sources

Figure 3: Three Major Monomers of Lignin: (a) Paracoumaryl Alcohol; (b) Coniferyl Alcohol; and (c) Sinapyl Alcohol

Figure 4: Structure of Cellulose Compositions

Figure 5: The Structure of Hemicelluloses (Xylan)

The hygroscopic nature is another major drawback of biomass. Though, biomass can be dried before its use, the hygroscopic nature makes it to reabsorb the moisture from the surrounding atmosphere even if it is stored indoors.

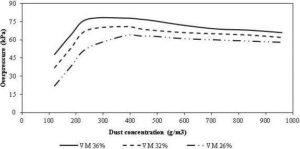

The fibrous nature of biomass increases the difficulties in pulverizing it into a fine powder as required for co-firing in pulverized coal fired boiler. This results in higher grinding costs, or reduces the generation capacity of the plant (Ratte et al., 2011; Wannapeera et al., 2011). The fibrous nature of biomass not only increases its grinding cost, but it is also responsible for the inconsistency in the particle sizes (Tumuluru et al., 2011). The pulverized particles from raw biomass are coarse and slender in nature (100-10mm) with a low sphericity values (Phanphanich and Mani, 2011). Such lower sphericity reduces its flowability, reducing the performance of the entrained flow gasifier (Melkior et al., 2011).

Biomass Pretreatment Methods

The above limitations of biomass are hindering the wide-scale use of biomass. This limitation can be reduced to some extent by pretreatment. Pretreatment alters the biomass such that enzymatic hydrolysis of cellulose, and hemicellulose can be achieved more rapidly and with a greater yield (Harmsen et al., 2010). The pretreatment also enhances its physical properties making it suitable for use in the existing energy conversion systems. However, for such process to be commercially viable, the technology should be well developed and economical feasible. Biomass pretreatment methods are classified into five categories: a) Chemical, b) Mechanical, c) Thermal, (d) Hydrothermal (wet), and (e) Biological. These pretreatment methods facilitate biomass conversion process, increasing the economical and environmental viability of biomass use (Almeida et al., 2010; Harmsen et al., 2010). The study on the chemical, mechanical, and hydrothermal pretreatment of biomass is beyond the scope of this paper; only a short discussion on them is presented here.

Chemical or Hydrolysis

The primary goal of the chemical pretreatment is to improve the biodegradability of cellulose in biomass by removing the lignin and hemicellulose (Zheng et. al. 2009). The Common chemical pretreatment techniques are catalyzed steam-explosion, acid, alkaline, ammonia fiber/freeze explosion, organosolv, pH-controlled liquid hot water, and ionic liquids pretreatments. In ethanol production, the chemical pretreatment separates lignin and hemicellulose, and enhances the hydrolysis of cellulose, increasing ethanol production (Sun and Cheng, 2002). The chemical pretreatment also changes the morphological structure, as well as the arrangement of different functional groups. For example, an alkali based on chemical pretreatment reduces the degree of polymerization, disturbs lignin structure, and breaks the linkages in different cell compositions (Agbor et al., 2011).

Mechanical

The mechanical pretreatment brings about only physical change of biomass. Milling, extrusion, and grinding are the major mechanical pretreatment methods (Harmsen et al., 2010). Milling increases the accessible surface area of biomass for it conversion processes. A comparative study of sugar yield of two mechanically pretreated biomass namely extrusion and grinding, found that the extrusion treated biomass shows higher sugar yield compared to the grinding for wheat bran (Lamsal et al., 2010). Similarly in the screw press pretreatment method, an increase in the pressure and temperature improves the extent of softening of biomass and, reduces the moisture level. However, mechanically pretreated biomass does not increase the hydrophobicity of biomass. One very poplar pretreatment method is pelletization, but it does not necessarily increases the surface area. During pelletization, the ground biomass is compressed with at a specified temperature into a regular shape. Such regular greatly increases the handling ease of biomass, but it does not have the ability to avoid the moisture reabsorption capacity.

Thermal

The thermal pretreatment is a slow heating process in which biomass releases its volatiles. This process modifies the physical, structural, and chemical properties of biomass. Torrefaction, which is a thermal pretreatment method, produces a carbon rich solid product. This process is different from the drying, because in addition to removal of moisture it involves some chemical transformations within the polymer constituents of the cell wall. These transformations reduce the mechanical strength of the biomass, and produce more brittle and less fibrous products. The thermal pretreatment also increases biodegradability of waste biomass in the biological conversion process. For instance, the thermally pretreated biomass at 70 °C and 90 °C increased the anaerobic biodegradability in a methane production process by 24% and 48%, respectively when compared with the raw biomass (Gonzalez-Fernandez et al., 2012). The thermal treatment enhances the fuel flexibility making a wide range of fuels suitable for firing in pulverized coal fired plant. For example, the microalgae produced, using the flue gas from a thermal power plant can be made suitable for co-firing in a PC boiler by the torrefaction process (Wu et al., 2012).

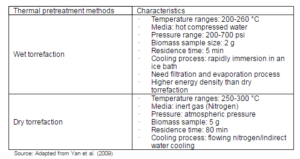

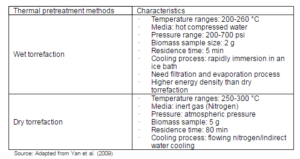

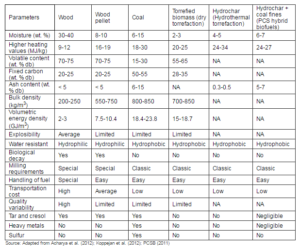

The thermal pretreatment, which mainly refers to the torrefaction process, can be divided into a dry and wet (hydrothermal) torrefaction (Yan et al., 2009). Table 3 gives different characteristics of the wet and dry torrefaction. The dry torrefaction is usually carried out in a dry inert environment and is described in more details in section 3.

The Hydrothermal

The hydrothermal carbonization may be defined as a thermochemical conversion process in which biomass is kept with water under a high pressure at moderate temperatures (180—230 °C) (Roman et al., 2012). The hydrothermal or the wet torrefaction uses either compressed water in a liquid form (Yan et al., 2010) or water mixed with acetic acid and lithium chloride (Lynman et al., 2011). The hydrothermal (wet) torrefier is an innovative reactor that could be used for treating a wet biomass such as animal manures, human waste, sewage sledges, municipal solid waste, aquaculture residues and microalgae. This overcomes the major limitation of dry torrefaction where the moisture content is limited to 15% (Koppejan et al., 2012).

The hydrothermal torrefaction is usually carried out in an autoclave or a specially made custom steel reactor. The hydrothermal torrefaction of biomass is mainly characterized by its ability to bring instability in the structure of lignocellulosic biomass, initializing the decomposition reactions at a low temperature. Hydrolysis is the primary reaction that alters physical structure of biomass in the hydrothermal torrefaction. Decarboxylation, dehydration, condensation, and aromatization are the four major reactions of the hydrothermal torrefaction (Funke and Ziegler, 2010).

The hydrothermal torrefaction can increase the energy density of biomass by up to 36% above that for the raw biomass (Yan et al., 2010). Though, the hydrothermal torrefaction adds more steps such as filtration and drying process compared to the dry torrefaction, its ability to treat the wet biomass increases the fuel flexibility making it more commercially attractive. For example, hydrothermal torrefaction can pretreat digested sludge from the anaerobic digester, increasing waste to the energy recovery from the agriculture residue (Oliveira et al., 2013). An aqueous waste stream from hydrothermal torrefaction contains substantial level of potentially valuable organic chemicals, such as sugars, furans, furfurals, and organic acids. The solution can also be used as a nutritional product that is applicable in growing algae (Jena et al., 2011). One potential major attraction of hydrothermal torrefaction is that it could lead to reduction in corrosion, and agglomeration causing elements in the biomass. A preliminary work of Dutta (2013) found an evidence of the major reduction in sodium and potassium content in the torrefied biomass.

Table 3: The Characteristics of the Thermal Pretreatment Methods

Another major advantage of hydrothermal torrefaction is its ability to produce an energy dense product in a relatively short period (5 minutes) of residence time (Coronella et al., 2012), while that for dry torrefaction it is between 30-60 minutes. The heat transfer rate in aqueous media is very high (Hoekman et al., 2013). This reduces the residence time of the hydrothermal torrefaction compared to the dry torrefaction. For instance, Yan et al. (2010) is able to perform the wet torrefaction of loblolly pine only within 5 minutes of residence time. In addition to this, the high working pressure around 20 bars reduces the carbon loss during the pretreatment (Libra et al., 2011). The solid product yield is further enhanced by the re-condensation reactions in aqueous solution. The re-condensation of liquid increases the carbon content in the torrefied biomass under the hydrothermal torrefaction. Thus, a hydrothermal torrefaction could produce a higher solid yield. The carbon loss per unit mass of feedstock increases with the amount of water mixed in the hydrothermal torrefaction, causing to a low net energy yield (Libra et al., 2011). For instance, a typical study on hydrothermal (wet) torrefaction results 10% reduction in energy yield compared with that of a dry method under the similar operating conditions (Chen et al., 2012).

To widen the range of moisture in feedstock for torrefaction technology, the PCS biofuels of Canada developed a hydrothermal polymerization process. This system consists of a reactor with liquid catalyst in which biomass is kept under moderately high pressure at a temperature around 250 ºC for a certain period of time. Biomass inside the reactor undergoes series of chemical reactions, forming water, carbon dioxide, and solid biofuels. Depending upon the type of catalyst used, different compositions of biomass, which are soluble in the liquid catalyst, are liberated out. In addition to this, the ability to recycle the liquid catalyst using cascaded reactor systems could reduce the thermal energy required for the process. Using an appropriate and hazards free catalyst also helps to use an aqueous solution of catalyst as a natural nutritional fertilizer for growing crops (PCSB, 2013).

The Biological Pretreatment

The biological pretreatment uses microorganism to modify the chemical composition and the structure of the lignocellulose biomass for making it suitable for the enzymatic digestion. The microorganisms used are white and brown soft-rot fungi, and bacteria (Zheng et al., 2009). The white-rot fungi, a major degrader of wood in the forest ecosystems, are the most effective microorganisms for the biological pretreatment of lignocellulose biomass (Akin et al., 1995; Chaturvedi and Verma, 2013). The biological treatment process seems to be a promising technology, as it avoids the use of chemicals, consumes less energy, produces minimal byproducts, works at mild operating conditions, and does not harm environmental (Wingreini et al. 2005). However, the biological pretreatment process is very slow and it requires a large space and a controlled environment for the effective pretreatment, which makes the process costly compared to other pretreatment methods (Zheng et. al. 2009).

Overview of Torrefaction

Torrefaction is a partial pyrolysis of biomass which is carried out under atmospheric pressure in a narrow temperature range of 200-300 °C, and under an inert environment (Bergman et al., 2005; Clausen et al., 2010; Medic et al., 2011; Prins et al., 2006). It produces three major products such as dark color solid products, yellowish color acidic aqueous products, and non-condensable gaseous products. Torrefaction is usually performed at a low heating rate, which gives a higher yield of solid product (Deng et al., 2009). Unlike pyrolysis, the major motivation of torrefaction is the maximization of the solid yield. Decomposition, devolatilization and depolymerization are the three major reactions that occur during the torrefaction process. This process releases condensable hydrocarbon, hydrogen, oxygen, and some carbon content from the biomass in the form of water, carbon monoxide, and carbon dioxide (Pach et al., 2002). During the torrefaction process, drying is considered to be a more destructive as it breaks inter- and intra-molecular hydrogen, C-O, and C-H bonds (Tumuluru et al., 2011). This leads to emissions of hydrophilic and oxygenated compounds, forming a blackened hydrophobic energy dense product.

Motivations for Torrefaction

The main motive of torrefaction is to upgrade the fuel quality of biomass to make it more suitable for the thermo-chemical conversion. A torrefied biomass can be used in briquetting, pelletization, gasification, and co-firing thermal power plants (Bridgeman et al., 2010; Felfli et al., 2005; van der Stelt et al., 2011). The torrefaction of biomass destructs the tenacity and fibrous structure of the biomass, and also increases its energy density. Numerous studies concluded that the torrefied biomass can avoid many limitations associated with the raw biomass because it produces moisture free hydrophobic solid products (Acharjee et al., 2011), decreases O/C ratio (Prins et al., 2006), reduces grinding energy (Repellin et al., 2010; Phanphanich and Mani, 2011), enhances energy density (Yan et al., 2009), increases bulk density and simplifies storage and transportation (Bergman, 2005; Phanphanich and Mani, 2011), improves particle size distribution (Phanphanich and Mani, 2011), intensifies combustion with less smoke (Pentananunt et al.,1990), shifts combustion zone to the high temperature zone in a gasifier (Ge et al., 2013), and increases the resistance to the biological decay (Chaouch et al., 2010). Many of these improvements make the torrefied biomass more suitable than the raw biomass for co-firing in the conventional coal power plants, with minor modifications (Clausen et al., 2010).

The removal of volatiles (light gases) during the torrefaction leads to a decreased in O/C ratio, and increased the energy density of the biomass. The losses of carbonyl and the carboxyl groups from cellulose, the carboxyl group from hemicellulose, and the aromatic ring and the methoxyl groups from lignin are the major sources of mass loss during this thermal treatment of biomass (Yang et al., 2007). These components have less energy content than the biomass as a whole.

Thus, their loss increases the energy density of biomass after torrefaction. The increase in the energy density in the torrefied product may also be due to the higher fraction of lignin (heating value of 25 MJ/kg), and a reduced fraction of hemicellulose and cellulose with heating value 18.6 MJ/kg (Gupta and Demirbas, 2010).

The hydroxyl group, which can establish ions and attract water molecules, is responsible for the hydrophilic behavior of biomass. The hydrophilic nature of biomass decreases as the torrefaction reduces the hydroxyl groups through decomposition reactions. The removal of hydroxyl groups also decreases the capability of forming hydrogen bonds that in turn reduces the moisture-absorbing capacity of biomass. This effect leads to the transformation of polar molecules into non-polar unsaturated molecules and produces a hydrophobic product.

The tenacious and fibrous nature of raw biomass established due to a complex structure of interlinked polymeric components increase the grinding cost of biomass. The heat applied during the torrefaction process modifies the complex structures of the interlinked polymeric components. It thus breaks down the hemicellulose matrix, and depolymerizes the cellulose structure, resulting in a decrease in the fiber length (Bergman and Kiel, 2005). The decomposition of the hemicellulose matrix produces mainly a light volatiles gases such as CO2, CO, CH4 and traces of H2 (Prins et al., 2006a). The decomposition and the depolymerization of the macro-polymeric components to the micro-monomers, which decreases fiber length as well as increases porosity, increase the grindability of biomass. The improvement in the grindability reduces slenderness in the ground particles, producing a uniform particle size distribution suitable for co-firing power plants.

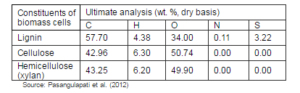

The Mechanism of Torrefaction

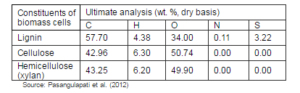

In the torrefaction process, the major changes and the transformation occurring inside the biomass can be predicted mainly by understanding the behavior of three polymeric constituents. For example, the hemicellulose — a highly reactive component — undergoes decomposition and devolatilization, and contributes a major part of mass loss in the torrefaction process. Therefore, the biomass materials with a high hemicellulose content have a lower solid product yield compared with that of the biomass with a low hemicellulose. The acetic acid and the methanol from acetoxy- and methoxy-groups are the major constituents of the volatiles gases released during the thermal degradation of the hemicellulose (Prins et al., 2006a). Although, only a small portion of the cellulose degrades within the torrefaction temperature range (200-300 °C), the water vapor and the acids released from the hemicellulose may also enhance the degradation of cellulose. The lignin that has more carbon than the other two polymeric constituents of biomass (Table 4) is thermally more stable and takes a larger share in the final solid product. The solid product with higher carbon content produces an energy dense product after the torrefaction.

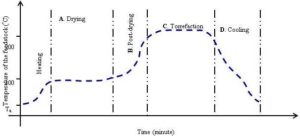

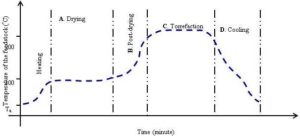

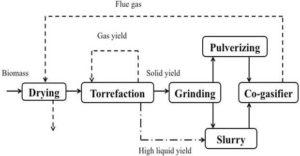

Dry torrefaction comprises of four simple steps (Fig. 6) such as:

(a) Drying, in which only the surface (free) moisture is removed,

(b) Post — drying, in which the bound moisture as well as some of the light hydrocarbons are removed,

(c) Torrefaction — isothermal heating — in which supplied heat establishes the depolymerization, partial devolatilization, and partial carbonization reactions

(d) Cooling process (up to an ambient temperature, Ta).

The overall cycle time of the dry torrefaction process is the sum of the time taken by drying, post-drying, torrefaction and cooling process. As one can see from Figure 6, the temperature remains unchanged during the drying, and the torrefaction with an important distinction that the energy used during drying is highest, and that during the torrefaction is much lower. As the destructive torrefaction starts only above 200 °C, the duration of the torrefaction, known as the residence time, is usually measured from the instant when the temperature of biomass exceeds that temperature (Basu, 2013).

While the wet torrefaction uses the concept of solubility of different compositions of biomass in hot and aqueous solutions, the dry torrefaction is characterized mainly by the thermal degradation of the polymeric constituents of the biomass. The degradation of the biomass during the dry torrefaction, therefore, can be explained through the drying and devolatilization process.

Drying

Drying is the major and the most energy intensive step in the torrefaction process. The drying process refers to the process of removing a surface and bound water from the raw biomass. Drying is classified as a non-reacting and a reactive process. Drying of biomass in the temperature range of 50-150 °C is known as non-reactive drying, when it mainly removes the surface water, resulting shrinkages in the product size (Tumuluru et al., 2011). The non-reactive drying is followed by the reactive drying in the temperature range of 150-200 °C at which the breakage of hydrogen, and the carbon bonds occur, emitting lipophilic extractives. This phase is characterized by a permanent structural deformation. The reactive drying substantially removes the bound water from the biomass.

Devolatilization

Devolatilization may be defined as a process of removing oxygen and volatile content of biomass. It generally occurs once the temperature of the biomass is above 200 °C at which volatiles (both gases and tar) start leaving the solid matrix of biomass (Basu and Kaushal, 2009; van de Weerdhof, 2010). It is also known as the destructive drying process, which is characterized by the devolatilization and carbonization of hemicellulose, depolymerization, devolatilization, and softening of lignin, and depolymerization and devolatilization of cellulose. However, it may be noted that the devolatilization is rarely complete during the torrefaction. The torrefied biomass always contains some volatile matters unlike the char produced from a pyrolysis process.

Table 4: Typical Elemental Analyses of Lignin, Cellulose and Hemicellulose

Figure 6: Stages of Torrefaction Process

The Effect of Design and Operating Parameters

Temperature

The mode of a torrefaction process may be classified as a light, mild, and severe torrefaction based on the torrefaction temperature range around 230°C, 260°C, and 290°C, respectively (Chen and Kuo, 2010). The temperature shows a dominant influence on the product quality of torrefaction. Solid yield of torrefaction product depends on the temperature. For instance, in one case the solid yield decreased from 94% to 56% when the torrefaction temperature increased from 220 °C to 275 °C (Felfli et al., 2005). On the other hand, Acharya (2013) in his study of the torrefaction of Oats, reported a decrease in the energy yield but an increase in the energy density when the temperature of the torrefaction increased from 210 °C to 300 °C. The mass loss or solid yield at different torrefaction temperatures can be explained mainly through the impact of the temperature on (i) polymeric compositions, and (ii) devolatilization rate.

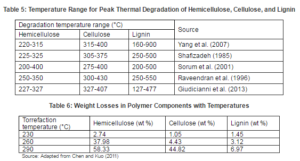

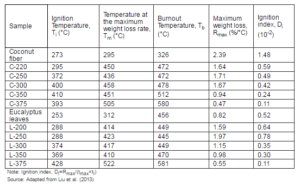

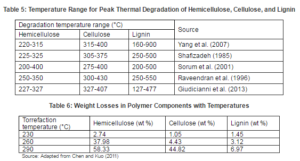

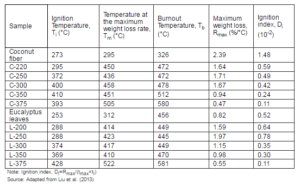

The polymeric composition of the lingo-cellulosic biomass, to some extent influences the nature of the torrefied products. Table 5 presents the temperature ranges over which the thermal degradation of the hemicellulose, cellulose, and the lignin takes place during the pyrolysis process. It indicates that the lignin decomposes over a wider temperature range than the other two components. The stability of the lignin is due to the thermal stability of its different functional groups containing oxygen (Brebu and Vasile, 2009). On the other hand, hemicellulose is highly sensitive in the narrow temperature range of torrefaction. The mass loss during the torrefaction therefore, it depends highly on the devolatilization of hemicellulose. The hemicellulose shows significant effects in the initiation and propagation of different pyrolysis reactions (Rousset et al., 2011). The composition of the hemicellulose also affects the degradation rate of the biomass. For example, biomass with higher xylan in hemicellulose is more temperature sensitive than the one with a mannan based hemicellulose (Basu, 2013). The celluloss are relatively stable to the temperature than the hemicellulose, because of the crystalline structured of the cellulosic fibrils. Breakage of these crystalline fibrils, which affects glucosidic bonds between glucose monomers, and inter and intra-molecular hydrogen bonds at a higher torrefaction temperature, reduces the strength of solid products (Emsley and Stevens, 1994). Table 6 presents typical mass loss percentages of the hemicellulose, cellulose and the lignin at different torrefaction temperatures.

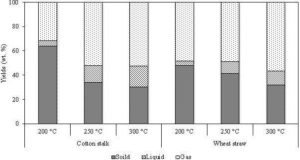

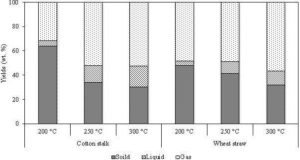

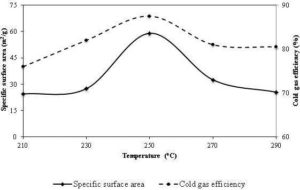

The devolatilization rate is defined as the rate of mass loss during the thermal degradation of the biomass and will be more at a high temperature. A higher heating rate of biomass at a higher operating temperature usually produces more volatile gases during the pyrolysis process, and increases the devolatilization rate. This reduces the solid product yield from the process. Figure 7 shows the effect of the temperature in the product distributions during the process of torrefaction of cotton stalk and wheat straw. The volatiles, which include both condensable, as well as non-condensable product, increased at a higher temperature torrefaction. In addition to this, the higher heating rate also affects the morphological structure of the solid product. More round pores are formed during the pyrolysis when the temperature increased from 600 °C to 800 °C (Guerrero et al., 2008). This establishes a larger internal cavity and more open structures.

The Residence Time

The residence time of the feedstock in the reactor is an important parameter for designing reactors. Compared to many other thermo-chemical conversion processes like combustion, gasification or pyrolysis, the reaction time for torrefaction is much longer. It is nearly an order of magnitude longer than that for other processes. Such a long reaction time requires the biomass feed to reside within the reactor for a very long time. This naturally increases the volume requirement of the reactor for a given output. The residence time has thus a greater impact on the reactor size. For example, the length and the rotational speed of the screw in a screw type reactor, and the belt speed in the conveyer belt reactor are mainly determined by the required residence time (Koppejan et al., 2012). The residence time also determines the solid space velocity and the reactor height of a moving bed torrefier.

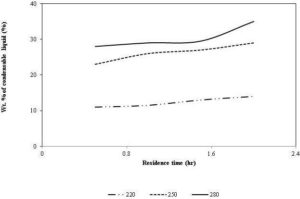

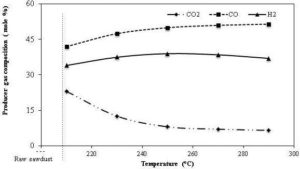

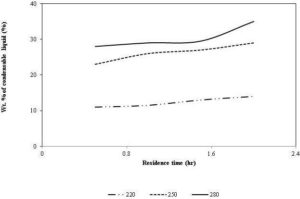

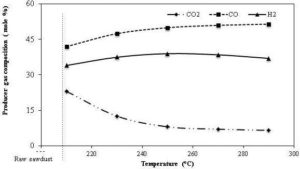

Although, the net effect of the residence time is not as prominent as that of the temperature, the residence time influences the torrefied product at longer residence time. The solid mass loss increases with residence time, resulting in a lower solid product yield (Chen et al., 2011, Acharya et al., 2012). This is due to an increase in the extent of devolatilization (Prins et al., 2006a). Condensable product contributes significantly to the solid mass loss at a higher residence time, as it increases with time as shown in Fig. 8. On the other hand, non- condensable product such as CO2 and CO reaches the peak value at a residence time of 10 minutes, and then starts declining (Bates and Ghoniem, 2012). The amount of methanol and lactic acid, which are produced during the decomposition of acetoxy- and methoxy-, groups (Tumuluru et al., 2012), increase up to 10 minutes and then remain unchanged (Bates and Ghoniem, 2012).

With an increase in the residence time, one expects an increase in the carbon content, and a decrease in the hydrogen and oxygen content of the torrefied product. For example, the carbon content of a palm kernel shell increased from 55% to 58% at a torrefaction temperature of 250 °C, when the residence time was increased from 30 to 90 minutes (Felfli et al., 2005). At the same condition, the oxygen content of the product was decreased from 31% to 29%. It is interesting that though the carbon content increases with the residence time, the absolute value of the carbon always decreases due to the increase in the reaction of carbon dioxide and the steam with the porous char (Prins et al., 2006a). They reported that a gradual decrease in CO2 and an increase in CO composition were found in the non-condensable volatiles when the residence time increased from 5 to 30 minutes. This suggests that the formation of CO increases in the secondary reactions occurring at a longer residence time, which increases the energy content of the volatile gas and reduces the overall torrefaction efficiency, especially if volatiles were not utilized. The quantity of CO2 and CO in volatile gases is significant only at higher torrefaction temperature (Deng et al., 2009). On the other hand, the relative amount of the carbon loss with that of the oxygen also increases with the rise in the residence time. For instance, Bates and Ghoniem (2012) found that the amount of carbon and oxygen losses was 11% and 40% in 15 minutes compared to 26% and 69% in 40 minutes, resulting more carbon loss per a unit of oxygen loss (from 0.275 to 0.377). This suggests that the rate of de-oxygenation of biomass slows down at the higher residence time, which increases the carbon content in the volatiles.

Figure 7: Effect of Torrefaction Temperature in Product Distribution of Cotton Stalk and Wheat Straw (Residence Time = 30 Minutes)

Source: Adapted from Wang et al. (2011)

Figure 8: Variations in Condensable Liquid with Torrefaction Temperature

Source: Adapted from Chen et al. (2011)

Oxygen Concentration

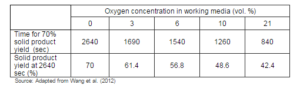

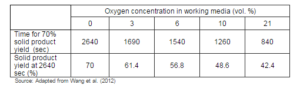

The presence of oxygen in the torrefaction media increases the extent of the combustion reactions, which converts a carbon into a flue gas instead of leaving it in a solid form. Additionally, the combustion in the reactor could increase the temperature of the product endangering the safety of the unit. Therefore, oxygen is not desirable for the safe and efficient operation of the torrefaction process. So, torrefaction would require either indirect heating or a continuous supply of hot inert gas. The latter option is not economically feasible. To minimize the energy cost, in a commercial torrefaction unit, the flue gas could be used as both a heat source and a working media. But the flue gas form a combustion process which is always associated with some free oxygen. To get more insight into the effect of this oxygen on the torrefaction, a brief review of this is presented below.

The solid product yield of torrefaction decreases when the oxygen is present in the working media. Uemura et al. (2013) and Basu et al. (2013) noted appreciable effect of oxygen on solid yield at 250 °C. The extent of this depends on the torrefaction temperature, but. Rousset et al. (2012) observed only negligible changes in the torrefied solid yield at around 250 °C.

The presence of the oxygen in the working media increases the devolatilization reactions that have the higher ability to remove the oxygen from the sample compared to that of the nitrogen media. But Rousset et al. (2012) observed only a slight change in the values of O/C and H/C for eucalyptus wood under the air and the nitrogen media. The O/C and H/C ratios decreased with the rise in the oxygen concentration.

However, some studies (Basu et al., 2013; Rousset et al., 2012; Uemura et al., 2013; Wang et al., 2012) found that oxidative media shows only a minor effects on the heating value of the solid product. Tumuluru et al. (2011) noted some increase in the heating value of willow, the red canary grass and the wheat straw with a rise in the torrefaction temperature in an inert medium. Lu et al. (2012) noted that the heating value of the oil palm fiber torrefied in the nitrogen is higher than that in the air, which agrees with the observation of Tumuluru, but that did not happen for eucalyptus, where oxygen had minor effect on HHV except above 300 °C. The other differences between these two biomass are that HHV of the air-torrefied oil palm fiber decreased steadily with the torrefaction temperature, while the torrefaction temperature had minor effect on HHV of eucalyptus torrefied in air. The data point being limited are not certain if this can be taken as an effect of the type of biomass.

Lu et al. (2012) made a comparative study of the torrefaction using the eucalyptus wood and the oil palm fiber in the nitrogen and air media. Both, solid and energy yield were less in the air media than that in the nitrogen for both oil palm fiber and eucalyptus wood, but the yields decreased with the torrefaction temperature for both types. Lu et al. (2012) used a new parameter (energy-mass co-benefit index to assess the effectiveness of a torrefaction process. Using this index, they concluded that the use of the air is suitable for the eucalyptus wood but not for the oil palm fiber.

The torrefaction under the oxidative media, however, reduces to the torrefaction process time required for a given mass loss (Wang et al., 2012). Table 7 presents the torrefaction time required for a torrefaction process at 280 °C with different oxygen concentration in the working media. In addition to the time saving, Wang et al. (2012) also proved that the flue gas with the oxygen could be used as a working media without any significant changes in the torrefaction process and the product. This reduction in the torrefaction could have much practical significance, as it might reduce the size of the torrefaction reactor, and therefore the capital investment required.

The Particle Size

The heat source is required to preheat, dry, and devolatilize the biomass for the torrefaction process. The amount of the heat required depends on the size, shape, and biomass properties. These parameters affect both the convective and the conductive heat transfer rate from the reactor to the biomass and within the biomass, respectively. A larger piece of biomass will have less surface area per unit mass, reducing the convective heat transfer rate. The larger particle may also have non-uniform heat distribution within the biomass due to the anisotropic and heterogeneous properties of the biomass. In addition to this, the larger particle may face difficulties with the volatile diffusion through it because of the high mass transfer resistance. Thus, the quality of the torrefaction process may not be identical for all particle sizes. In this context, the effect of the particle size may be analyzed by estimating the Biot and the Pyrolysis number of the process.

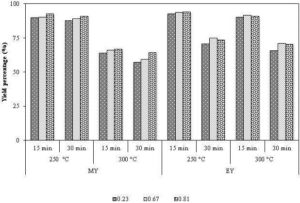

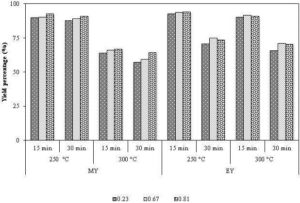

The Mass loss due to the torrefaction in the smaller particles (size varies from 0.23 to 0.81 mm) is higher than that in the larger particles (Peng et al., 2012) due to both, the lower resistances to the diffusion of volatiles and the higher heat transfer rate in small particles. For example, Medic et al. (2011) noted a higher mass loss in the ground corn Stover compared to that of the whole Stover. Even in a bubbling bed reactor that is characterized by a high heat transfer rate, Kokko et al. (2012) found a higher mass loss in the smaller particle compared to that of the bigger particle. A finer particle size also increases the mass losses in the microwave-assisted torrefaction process (Wang et al., 2012a). They observed the mass reduction ratios of 65%, 69%, and 72%, when the particle sizes were in the range of 0.149-0.297mm, 0.149-0.074 mm, and < 0.074 mm, respectively. The greater intra-particle effect and the heat transfer area in the fine particles causes a higher reaction temperature, enhancing the devolatilization reactions. The effect of the particle size on the mass and energy yields in torrefaction at different temperature and time is shown in Fig. 9. It shows a small but consistent increase in the mass and energy yields.

On the other hand, a study on a large cylindrical particle (size varies from 5 to 25 mm diameter with a constant length of 65 mm) observed a lower solid product yield when the diameter of the particle size increased (Basu et al., 2013a). They also found that in the large particle size the core temperature of the particle was greater than that of the furnace it was in, indicating the exothermicity of the torrefaction process. This is due to the higher heat transfer resistance in the large particles compared with that of the smaller particles.

Figure 9: Particle Size (mm) Effect on Mass and Energy Yield at Different Temperature and Time

Source: Adapted from Peng et al. (2012)

Table 7: Reduction of Process Time for Similar Output in Torrefaction Process under Oxidative Environment at 280 °C

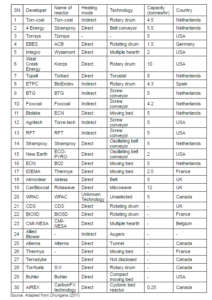

The Reactor Type

The torrefier — based on the mode of heat transfer — is broadly classified into two types: (i) direct heating and, (ii) indirect heating (Dhungana et al., 2012a). the most common reactors such as moving bed, augur, entrained bed, microwave, fluidized bed, hydrothermal, and rotary drum reactors fall within one of these two categories. The movement of biomass, the working media, and the heat transfer mechanism are the most important distinguishing features of the reactors. These features determine the nature of the torrefied products, as well as the total torrefaction time. For example, the rotational speed, length of the drum, and the tilt of the drum characterizes the rotary drum torrefier (Koppejan et al., 2012). The rotational speed determines the heat transfer rate, whereas the drum length affects the residence time. In Torbed (fluidized bed) reactor, where the heat carrier fluid move at a relatively high velocity, is characterized by its intense heat transfer rate. This reactor can produce the torrefied biomass at a very shorter residence time (around 80 sec), while using fine particles (Koppejan et al., 2012). The major advantages and disadvantages on different types of reactors are presented in Table 8.

A comparative study between different reactors — keeping all other conditions the same is presented in Dhungana et al. (2012a) in which they observed that rotary drum reactor has lower solid product yield compared to that for convective reactor and fluidized bed reactor. This could be due to the differences in the gas to the particle heat transfer in the specific reactor type. In the rotary drum reactor, the primary heat transfer from the reactor to the particle is through the thermal conduction between the reactor wall and particles. The possibility of a high heat transfer rate to the particle due to a continuous tumbling action of the particle with the rotational movement of the reactor, may be one of the reasons behind the lower solid product yield in rotary drum reactor. Additionally, the high heat transfer to surface of the large particles could give a higher temperature in the particle core. This may also increase the mass loss.

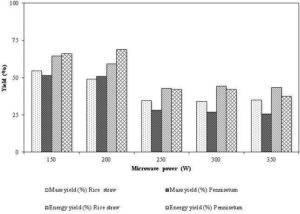

The microwave torrefaction uses the microwave irradiation as a heat source, which is characterized by its fast internal and uniform heating properties (Ren et al., 2012). The microwave heating can be achieved by two mechanisms viz. the rotation of dipoles, and the migration of ions (Huang et al., 2012). The microwave torrefaction requires moisture content less than 10% but it is not necessary the particle to be small (Wang et al., 2012a). the characteristics of the microwave torrefaction depend on the type of materials and their ability in absorbing the microwave radiation. Since the microwave torrefaction is powered by the microwave irradiation, torrefaction temperature; and the biomass-heating rate depend highly on the power of the microwave. This alters both physio-chemical properties of torrefied product, especially in the morphological structure. A higher microwave power could achieve the torrefaction temperature of biomass in the reactor in a very short period of time, and thus significantly reduce the processing time (Huang et al., 2012). However, in the large particles there may be significant temperature gradient in the particle resulting in a non-uniform torrefaction (Dhungana, 2011). Huang et al. (2012) did not notice this effect as they used small particles of average diameter 0.297 mm.

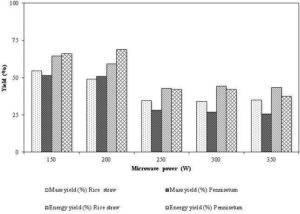

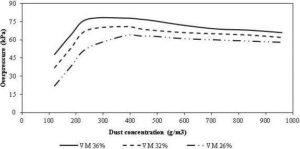

Figure 10 shows how the mass and energy yields decrease with the increase in the microwave power. A significant loss in the masses of rice husk and Pennisetum at a higher microwave power is due to the higher torrefaction temperature obtained at 25 minutes residence time. The temperature of biomass in the reactor rose well above 300 °C at 25 minutes when the microwave power was in the range 250-350 W. Huang et al. (2012) also showed that the biomass temperature increased with both, the time and microwave power. At higher microwave power, the torrefaction temperature exceeded 300 °C within 10 minutes and such fast heating rate is known to reduce solid yield (Basu, 2010). Thus, being an energy efficient heating method and a high potential to release volatiles in a short time interval, the microwave torrefaction has a higher possibility of enhancing the porosity of products, and improves the combustion properties of the biomass. The information on the morphological changes in the biomass with the microwave power, and the combustion and gasification characteristics of the solid product under the microwave torrefaction are still unavailable in literatures.

Table 8: Advantages and Limitations of Different Types of Torrefaction Reactors

Figure 10: Effect of Microwave Power in Solid Product (Mass) and Energy Yields of Rice Straw and Pennisetum under the Microwave Torrefaction at Residence Time of 25 Minutes

Source: Adapted from Huang et al. (2012)

The Effect of the Torrefaction on the Biomass Properties

The torrefaction process has significant effects on the different properties of the biomass such as the proximate analyses, ultimate analyses, solid residue, heating values, hydrophobicity, grindability, density and the volume of the sample. In the following sub-sections, the changes in these properties of the biomass due to the torrefaction process are discussed.

Proximate and Ultimate Analysis

The torrefaction process converts the complex polymers of biomass into the smaller monomers, and then the smaller monomer into condensable and non-condensable volatile gases. This transformation alters both, the proximate and ultimate analyses of the biomass. The Torrefaction drives away the volatile matter, as well as fixed carbon from a biomass due to the decomposition and the devolatilization reactions. Although, the absolute amount of the fixed carbon decreases after the torrefaction process, the fraction of the fixed carbon in the torrefied biomass increases. However, the fraction of ash, the inert and non-combustible material in biomass increases even more, because none of it is driven away during the torrefaction.

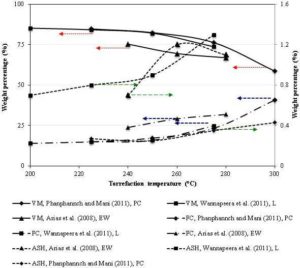

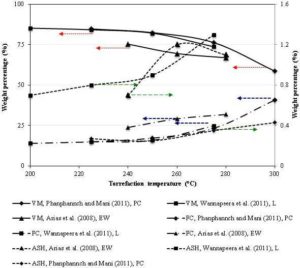

The decrease in the volatiles along with the chemical transformation of the remaining polymeric components produces a brittle carbonaceous coal like solid torrefied products. The torrefied product would, therefore, have a proximate and ultimate composition different from that of the parent biomass. The change in the proximate composition of the torrefied biomass is influenced by both temperature and residence time of torrefaction. The increase in time and temperature reduces the volatile content of biomass (Arias et al., 2008). The typical proximate analyses of the torrefied Pine chips, Laucaena, and Eucalyptus wood at different torrefaction temperature is shown in Fig. 11.

Moisture loss, which is one of the components in condensable products, makes a major contribution to the total mass reduction. The typical condensable products including tars were observed more than 50% of the total mass loss at all operating conditions (Chen et al., 2011). Longer residence time releases more volatiles gases and leads to the evolution of a secondary volatiles gases, which has relatively a higher energy value than the first stage volatiles. For instance, Bates and Ghoniem (2013) found that the first stage volatile in the two-step torrefaction kinetics has heating the value of only 4.4 MJ/kg compared to 16 MJ/kg in the second stage volatiles.

Figure 11: Volatile Matter (VM), ash Content (ASH), and Fixed Carbon (FC) Content of Biomass in wt. % Dry Basis with Torrefaction Temperature at a Residence Time of 30 Min (PC=Pine Chips, L=Laucaena, and EW=Eucalyptus Wood)

The carbon usually contributes 60-85% of the total mass of the coal composition, whereas the oxygen content ranges from 5-20% (Prins et al., 2007). Biomass on the other hand contains much lower carbon (50%) but much higher oxygen (45%). This indicates that O/C ratio of biomass is very high compared with that of coal. This significantly reduces the energy density of biomass. Therefore, torrefaction — a technology capable of reducing O/C in biomass — has a greater impact on the energy density of biomass.

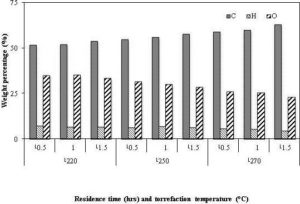

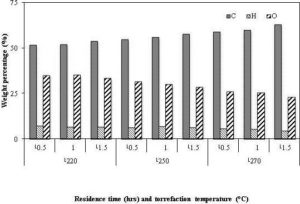

Arias et al. (2008) found about 26% reduction in the oxygen and 24 % increment of carbon content in the eucalyptus wood after it is torrefied at 280 °C for 3 hours. These changes are in contrast with that of Chen et al. (2011) who observed around 45% less oxygen and 44% more carbon content in the Lauan block after it is torrefied at 280 °C in 2 hours. This indicates that the longer residence time alone does not necessarily have a major effect on the change with carbon and oxygen content in a biomass. Other than operating conditions, changes in the ultimate analyses also depend on the particle size, type of materials, and the method of torrefaction. The rate of increasing carbon content is higher in severe torrefaction condition. For instance, the carbon increment rate was found 0.88 wt. % of dry ash free carbon per hour at 220 °C, while it was 1.55% and 3.66% per hour at 250 °C and 280 °C, respectively. While the carbon content was increased in the torrefied products, both oxygen and hydrogen were decreased (Bridgeman, et al., 2008; Felfli et al., 2005). A typical chemical composition of briquettes after torrefaction is shown in Fig. 12. The one easily notes here that while the carbon percentage increases, the hydrogen decreases with both temperature and residence time.

Figure 12: Chemical Composition (in Dry and Ash Free Basis) of Briquette at Different Torrefaction Temperature and Residence Time

Source: Adapted from Felfli et al. (2005)

Solid Product and Energy Yield

The solid product yield and the energy yield are important quantitative and qualitative measures of a torrefaction process. The solid product yield is defined as a ratio of the final mass of the solid torrefied product to the initial mass, whereas the energy yield is a ratio of the final energy in the solid product to the initial energy content of the raw biomass. Both the solid product and the energy yields are expressed in dry basis or in dry and ash free (DAF) basis.

Solid Product Yield

The torrefaction process yields solid, condensable (liquid), and non-condensable products (light volatiles) among which solid is the desired product (Wang et al., 2011). The fractions of the individual products vary with operating conditions. The solid product is made of original sugar structures, modified sugar structures, newly formed polymeric structures, and ash content, whereas the condensable products comprise mainly of water, organics (sugars, poly-sugars, acids, alcohols, furans, and ketones), and lipids (tarpenes, phenols, waxes, fatty acids, and tannins). The non-condensable product is a mixture of gases like CO2, CO, CH4, CxHy, toluene, and benzene (Bergman, et al., 2005a; Yang et al., 2007). The condensable product contains water vapor and heavy tars. This liquid fraction of the torrefaction product depends on the process temperature and time. Figure 8 shows how the fraction of the condensable product changed with the residence time and temperature in a typical case. This effect might be due to the decomposition of the molecules with hydroxyl groups, releasing more water vapor. For instance, an increase in water vapor from 7.6 % to 17.8% was reported in Wannapeera et al. (2011) when the torrefaction temperature increased from 200 °C to 275°C.

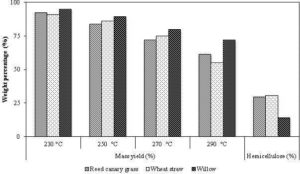

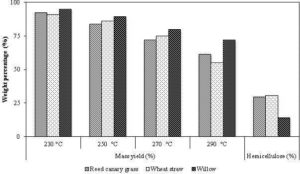

The fraction of solid product yields varies widely from 50% to 97% (Felfli et al., 2005) depending on the temperature and residence time. The solid yield also depends on the type of the biomass materials (Prins et al., 2006a). Figure 13 shows how the solid product yield depends on the hemicellulose content of the biomass. It reveals that the lignocellulosic biomass with higher hemicellulose composition has lower solid product yield. For instance, the willow, which has the least hemicellulose content of 14% compared to 30% with that of reed canary grass and 31% with that of wheat straw, shows the highest solid product yield (Bridgeman et al., 2008). The high-pressure like a pressurized torrefaction system could increase the solid product yield. This could be due to the possible trapping of the heavy volatiles within the pores of biomass. However, the trapped heavy volatiles may devolatilize into light volatiles that easily escape from the biomass when the torrefaction temperature, and the residence time are increased. For instance, Wannapeera and Worsauwannarak (2012) found an increase in the solid product yield from 88.2% to 89.9% at 200 °C, when the reactor pressure increased from the atmospheric condition (0.1 MPa) to 4 MPa. But they also observed a gradual decrease in the solid product yield with a rise in the temperature from 225 °C to 250 °C.

Energy Yield

The losses in the quantitative measure (solid product yield) do not show any importance while selecting an operating condition of the torrefaction process. The higher mass loss could be desirable if the qualitative measure (energy yield) is within an acceptable range. Therefore, the quality of the solid product, which is measured in term of the energy density of torrefied biomass, is of a greater importance.

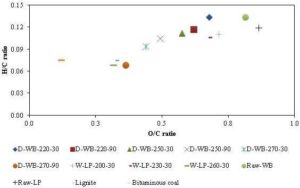

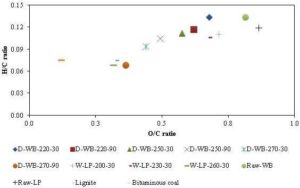

The heating value of the torrefied biomass increases because it has more C-C and C-H bonds with the aromatic molecules (Ben and Ragauskas, 2012) with an ability to release more energy than O-H and C-O bonds in the raw biomass. The reduction in the hydrogen and oxygen reduces the O/C and the H/C ratios of biomass. This moves the torrefied biomass towards the coal side in the Van Krevelen diagram (Fig. 14). The higher torrefaction temperature and residence time decrease O/C and H/C ratios and move the torrefied product close to that of the coal. This suggests that the formation of CO2 and H2O increases with the temperature and residence time due to the release of oxygen from biomass. For example at different residence time and temperature, the O/C of the deciduous wood decreases from 0.70 to 0.52 (Prins et al., 2006). The biomass with higher hemicellulose, which has the highest oxygen compositions, is more likely to produce an energy dense product. This indicates that the energy density of the solid product also depends on the type of the biomass. But the question is how the energy density varies with the type of biomass. Higher the lignin content, the more energy will be extractable from the biomass. Thus, the torrefied solid product from a biomass with higher lignin content becomes more energy dense fuel compared to others with lower lignin content. Thus, a complete elimination of both cellulose and hemicellulose contents of the wood produces a product that could have energy density similar with that of the coal. Ben and Ragauskas (2012) noted that the energy density of the loblolly pine increased to 32.34 MJ/kg when the torrefaction was carried out at 300 °C for 4 hours.

Figure 13: Energy Yield and Solid Product Yield (Mass Yield) in Dry and Ash Free Basis from the Torrefaction of Reed Canary Grass, Willow and Wheat Straw (Residence Time of 30 Minutes) Showing Effect of Temperature and Biomass Type

Figure 14: Van Krevelen Diagram of Different Fuels (Notation: Type of Torrefaction-Biomass Type-Temperature-Time; D=Dry Torrefaction; W=Wet Torrefaction; WB = Briquette of Wood (Felfli et al., 2005); LP= Loblolly Pine (Yan et al., 2010); and Lignite and Bituminous (McKendry, 2002))

An increase in the energy density of torrefied solid product could be expressed as an energy enhancement factor (EDF), which is defined as a ratio of higher heating value of torrefied to that of the raw biomass. This is different from the energy yield, but could be used to determine it. The energy yield of a torrefaction process also varies with the type of biomass. The biomass with higher lignin content produces higher energy yield because they have higher solid product yield, as well as a higher energy density enhancement factor. For instance, Bridgeman et al. (2008) observed the energy yields of 77%, 78% and 86% for wheat straw (7.7% lignin), reed canary grass (7.6% lignin), and willow (20% lignin), respectively after they are torrefied at 270 °C for 30 minutes. The willow with 20% initial lignin content attained the energy density enhancement factor of 1.196 compared to 1.095 by reed canary grass and 1.118 by wheat straw.

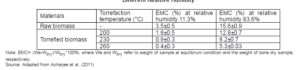

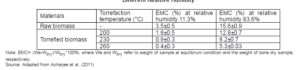

Hydrophobicity

Torrefaction substantially removes both free and bound moisture of biomass. The free moisture inside capillaries of fibers shows the surface wetness, whereas the bound moisture determines the hydrophilic or hygroscopic (affinity for water) nature of biomass. Though, drying could remove the surface moisture as well as some of the bound moisture of biomass, its hydrophilic property makes it regain the moisture from the surrounding air when stored. Equilibrium moisture content (EMC) of raw biomass influences its hygroscopic nature. Lowering the EMC reduces the moisture absorbing capacity, and thereby increases the hydrophobicity of biomass. The equilibrium moisture content also depends on the chemical composition and functional groups of biomass (Acharjee et al., 2011). The EMC highly varies with the relative humidity of air. Table 9 shows how a variation in EMC of a hydrothermally torrefied biomass is influenced by the temperature and relative humidity of the air in an atmospheric pressure. The torrefaction process has a positive effect on the humidity uptake from the air. The torrefied pellets can be considered more hydrophobic than the reference biomass pellets. A higher torrefaction temperature also has a favorable influence on the hydrophobicity. The wood and straw pellets are known to disintegrate quite rapidly when exposed to water. After 15 minutes of immersion water, absorption in the wood pellet is 76% while that of the torrefied pellet reduces it to 55% (Torrent, 2011).

The ability to resist the bound moisture is known as a hydrophobic nature of biomass. Hydrophobicity is also related to its ability to destruct hydrogen bonds. Decomposition of hydroxyl groups and lignin coating in biomass particles are believed to be the major causes of increasing hydrophobicity in torrefied biomass (Li et al., 2012). Torrefaction can reduce the EMC of biomass down to about 3% (Lipinsky et al., 2002). Equilibrium moisture content is directly related to the moisture absorption capacity of biomass. Li et al. (2012) found a reduction in the moisture adsorption capacity from 20.7% wt. to 13.6% wt. in the torrefied pellets. Similarly, Sule (2012) analyzed the effect of the temperature on the moisture absorption capacity and they found about 20% drop in the moisture absorption when the torrefaction temperature increased from 230 °C to 270 °C. the reduction in the moisture reabsorption capacity of biomass is due to the ability to break and remove carboxyl and hydroxyl groups during torrefaction. This type of pretreatment of biomass will be a good as it converts biomass into non-polar substances, which are less capable of forming hydrogen bonds. For instance, Shoulaifar et al. (2012) clearly noted a decrease in the EMC of torrefied spruce wood with a destruction of the carboxylic groups.

Grindability

Biomass possessing visco-elastic and plastic behaviors dissipates much energy before failure, increasing the energy cost of grinding (Repellin et al., 2010). The energy required for grinding process of any materials could be defined as its grindability. The main limitations in the grinding of the raw biomass are fibrous and tenacious natures, which create difficulties in the grinding. Thus, the process that reduces fibrous and tenacious behavior of biomass enhances the overall performance of the size reduction equipment.

Grindability is characterized by the nature of the particle size distribution, and the sphericity of the particles. Grindability is usually expressed by the Hardgrove Grindability Index (HGI) that measures the level of difficulty in the grinding solid sample into the powder form (Wu et al., 2012). The higher the value of HGI, the more easily a solid fuel can be reduced to the fine powder (Shang et al., 2012; Wu et al., 2012). The value of HGI of the torrefied biomass increases with the residence time and the torrefaction temperature (Wu et al., 2012). This is due to the harder and more brittle nature of the torrefied product. Wu et al. (2012) speculates that the rearrangement of the structure and the depolymerization of different molecules during the thermal treatment are one of the reasons of producing such hard and brittle product. Shang et al. (2012), on the other hand, reported that the removal of the hemicellulose during the torrefaction process is the main reason of increasing the HGI value of the torrefied product than the raw biomass.

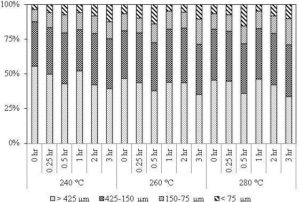

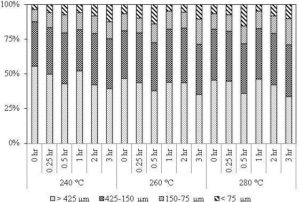

The decrease in the fibrous nature of the torrefied biomass produces more spherical and isolated particles when grinded. This improves in the co-milling and blending of biomass with coal, and then increases the co-firing potential of biomass in coal-fired power plants (Bridgeman et al., 2010). An increase in the sphericity of the particle or a decrease in the slenderness of particle was also presented in Arias et al. (2008). Figure 15 shows the changes in the particle size distribution of biomass torrefied at different residence time and torrefaction temperature. It shows that the fraction of the finest particle size (< 75μm) is maximum at the torrefaction temperature of 280 °C and residence of 30 minutes.

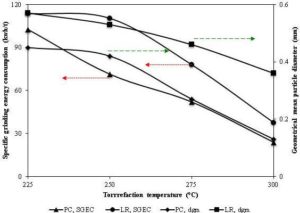

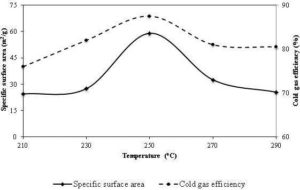

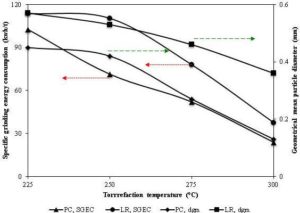

As discussed before, the torrefaction with an ability to reduce fibrous nature in the torrefied biomass, it significantly reduces the energy required for grinding wood (Bergman et al., 2005). For instance, Svoboda et al. (2009) reported a decrease in the milling energy by 3-7 times than the untreated biomass. However it varies with operating conditions of the torrefaction. Repellin et al. (2010) found that the grinding energy of torrefied spruce is reduced to around 100 kWh/tonne and 400 kWh/tonne at 280 °C and 200 °C, respectively compared with that of 750 kWh/tonne for the raw spruce. The energy required for grinding or milling also varies with the type of biomass, the level of the moisture content, and the extent of fineness. A decrease in a specific grinding energy by one-tenth (from 237.7 kWh/tonne to 23.9 kWh/tonne) for pine chips, and one-sixth (from 236.7 kWh/t to 36.7 kWh/t) for logging residues was noted when the biomass was torrefied at 300 °C for 30 minutes (Phanphanich and Mani, 2011). Similar results were also reported for rice straw and rape stalked in Deng et al. (2009). Figure 16 shows the changes in the specific grinding energy consumption, and the mean particle diameter of the pine chips, and the logging residues at different torrefaction temperatures. It shows that both mean particle size specific grinding energy consumption decreases with temperature. The effect was more prominent in the torrefied pine chips than in the logging residues.

Along with the grinding energy, the particle size distribution, sphericity and particle internal surface area also determine the flowability and combustion behavior in the co-firing plants (Tumuluru et al., 2011). The mean particle size of the ground torrefied biomass as shown in the Fig. 16 decreases with the torrefaction temperature (Deng et al., 2009; Phanphanich and Mani, 2011). The particle size distribution curve also skews more towards lower particle sizes at different torrefaction temperature compared to untreated biomass (Phanphanich and Mani, 2011; Repellin et al., 2010). Repellin et al. (2010) suggested a linear relationship between the particle size and the anhydrous weight loss during the torrefaction. The fineness of particle after the torrefaction of the raw biomass not only depends on the operating condition but also varies with the type of biomass. For example, Phanphanich and Mani (2011) found the fineness fraction of the particle 82% in the pine chips, and 51% in the logging residues. This difference in the fineness of the particle, though the solid product yields are similar for both pine chips and logging residues, is not well explained in literatures. Thus, torrefaction because of its potential to reduce the fibrous and tenacious nature, the net grinding energy, the slenderness ratio, and the particle size is being promoted as one of the important biomass pretreatment methods.

Table 9: Variation of the Equilibrium Moisture Content (EMC) with Hydrothermal Torrefaction Temperatures at Different Relative Humidity

Note: EMC= (We-Wdry)/Wdry*100%; where We and Wdry refer to weight of sample at equilibrium condition and the weight of bone dry sample, respectively.

Source: Adapted from Acharjee et al. (2011)

Figure 15: Distribution of Particle Size at Different Operating Conditions of Eucalyptus Wood (Particle Distribution of Raw Eucalyptus Wood 71% >425; 18.7%, 425-150; 4.7%, 150-75; and 5.4%, < 75)

Source: Adapted from Arias et al. (2008)

Figure 16: Temperature Effect on Specific Grinding Energy Consumption in kWh per Tonne and Geometrical Mean Particle Diameter of Pine Chips and Logging Residues

Source: Adapted from Phanphanich and Sudhagar (2011)

Density and Volume of Particle

For the design of the biomass handling and the transport systems, a good knowledge of its density and volume change after torrefaction is necessary. The devolatilization process creates voids due to the escape of the volatiles and thereby, reduces density of the product. Shrinkage in the physical dimensions (length and diameter), which reduces volume of the product, also occurs during the biomass devolatilization process. It may reduce the extent of density reduction due to the mass loss. The shrinkage of solid is due to the loss of water, rearrangement of chemical bonds, and the coalescence of graphite nuclei within the solid structure (Moghtaderi, 2006). The shrinkage of particle is significant at high temperature (1000-1300°C) pyrolysis and in thermally thick particles (Biot number > 10) (Moghtaderi, 2006), but it may also be observed at a low temperature torrefaction. Only limited information is available on the impact of torrefaction in the shape and size of particle. A preliminary study of Basu et al. (2013a) found that both volume and density of the cylindrical poplar are reduced after the torrefaction process. They found that the decrease in the diameter was higher compared with that of the length of the product. They also reported that the changes in the dimension are due to the drying process below the fiber saturation point, and the devolatilization reactions causing to the damages in fibers. In addition to this, the density of torrefied product at a given torrefaction temperature was found higher in a slender particle with high length to diameter (L/D) ratio. This is due to the higher solid product yield at a higher L/D of the particle (Basu et al., 2013a).

Generally, the raw biomass swells because of moisture. The swelling of biomass occurs when the water vapor diffuses into cell lumen and then from the cell lumen to the cell wall. Swelling of woody biomass is a reversible process that continues to swell until the moisture level reaches to the fiber saturation point, and starts shrinking once it loses the moisture below that point (Rowell, 2005). The water molecules attracted by the hydroxyl groups of polymeric components of the lignocellulosic biomass also occupy the space between the cell wall components (Homan et al., 2012). The torrefaction process not only removes the moisture, but also increases the non-polar molecules in the wood through devolatilization and depolymerization reactions. This naturally brings some changes in the physical size of the particle.

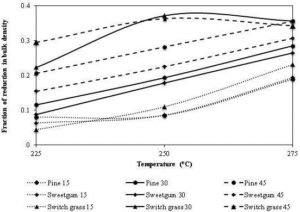

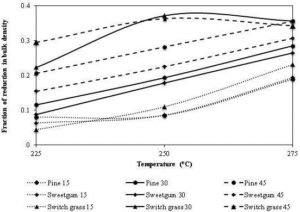

Torrefaction reduces the bulk density of biomass, though because of its less sharp shape one would expect higher packing density. Torrefaction however, increases the porosity of biomass. The increase in the porosity reduces the density of the torrefied product. Changes in the density depend on the operating parameters of the torrefaction as well as the type of biomass. Figure 17 shows the variation in reduction of bulk density of biomass after torrefaction at different temperature and residence time. The porous product becomes more brittle, that significantly reduces the power required for the size reduction compared to that of the raw biomass. In addition to this, torrefaction reduces the slenderness of particle, increasing the sphericity of the ground particles.

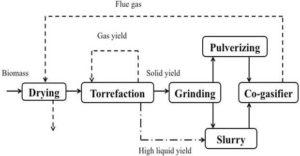

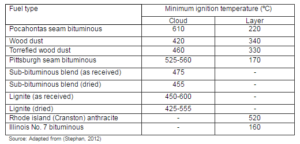

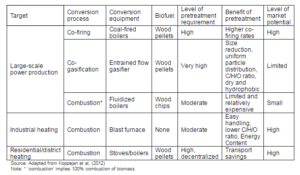

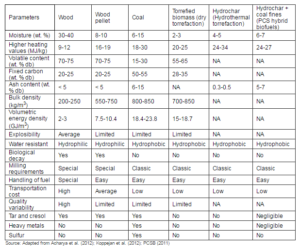

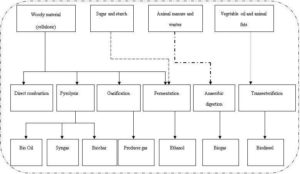

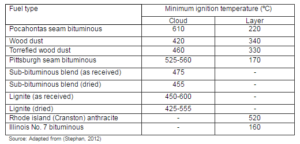

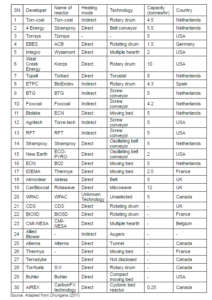

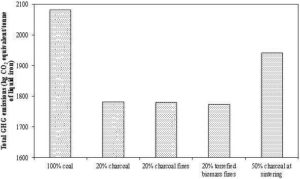

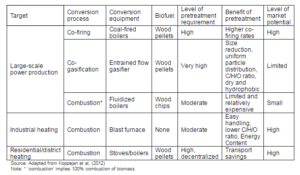

The Color of the Torrefied Products