Introduction

Maximising an asset’s operational time is one of the most important aspects of EAM. Sun et al. (2006) and Yao et al. (2005) claim that operating and maintaining today’s physical assets are more complicated due to their having more functions than ever before. Lack of proper maintenance issues combined with human errors leads to inefficiency of asset management and damage to assets. Consequently, this scenario reduces total production and human potential. Amy et al. (2005) found that unexpected troubles cannot be addressed by self-maintained base on experiential rule. The importance of maintenance function has increased because it plays an important role in retaining and improving system availability and safety, and product quality (Tsang, 2002). Hodkiewicz (2006) states that engineering assets in industries rely highly on their maintenance division to maintain and ensure assets are delivered properly. This author also revealed that in the last 30 years, the practice of doing maintenance has significantly changed due to developments in equipment design, information and communication technology, cost pressures, customer acceptance of risk and failures (Hodiewicz, 2006) and the existence of multiple stakeholders and departments (Snitkin, 2003). Moreover, current working circumstances are more complex and therefore need to be managed by multiple and interlinked activities (Camacho et al., 2008). Hence, an integrated high-level maintenance system which contains multiple sub-systems requires the collaboration of multiple stakeholders such as departments or units to improve resources, information sharing and maintenance practices.

Based on a review of some relevant references (Fernando & Smyth, 2001; Besten, Dalle & Galia, 2006; Rein, 1993) it is found that many organizations already have a collaborative maintenance system in place. However, with proper collaboration and commitment, that system can be expanded in scope and effectiveness. The very popular maintenance information systems that have been implementing for engineering asset maintenance are Computerised Maintenance Management Systems (CMMS) (Tam & Price, 2006). However, although such system makes a great volume of information available for reliability and efficiency analysis of the delivery of the maintenance function, most experts agree that successful CMMS is less than 30% of total applications (Zhang et al., 2006). The main reasons according to Bradshaw (2000) and Olszwesky (n.d) are: selection errors, insufficient commitment, lack of training, failure to address organizational implications, underestimating the project task, lack of project resources and lack of demonstrable use of system output. Clearly, most of the main reasons for unsuccessful implementation mentioned above are organisations and personnel requirements, while most of literature series are explored the technological requirements in the area of hardware, software and networking. The lack of systematic approach, together with the lack of specific requirements to implement computerize maintenance information systems including mobile collaborative asset maintenance system requests a comprehensive framework for guiding engineering organization for implementing of new mobile technologies that meet all maintenance collaboration requirements, including technology, organisation and personnel perspectives.

This paper is structured as follows: the first section describes the important of asset maintenance and the gap of literature. The second section provides a brief review of the concept of engineering asset maintenance, mobile collaboration technology for engineering asset maintenance. This is followed by a brief description of the research methods, proposed framework, and the last section outlines a conclusion.

Literature Review

Engineering Asset Maintenance

According to Tsang (2002), maintenance is a critical support function in industries where companies own engineering assets. Maintenance plays a central role in meeting the objectives of organizations. Similarly, Al-Sultan and Duffua (1998) conclude that maintenance provides a significant role in retaining or restoring machinery and equipment so that they perform their required functions. Currently, maintenance is acknowledged as a major strategy in maintaining productivity for an engineering assets organization over the long-term.

Maintenance has a major relevance to the business performance of industry. Whenever a machine stops due to a breakdown, or for essential routine maintenance, it incurs a cost. The cost may simply be the costs of labour and the cost of any materials, or it may be much higher if the stoppage disrupts production (Pintelon & Muchiri, 2009). In order to define how far such interruption (due to wear, tear, fatigue and sometimes corrosion) has impacted plant and/or machinery of engineering assets, inspection is required systematically. Routine or systematic maintenance plays an important role as a requirement to achieve certain production targets.

As explained by Dekker (1996) the maintenance’s role could be defined by the four objectives it seeks to accomplish. They are:

- Ensuring system function (availability, efficiency and product quality). For production equipment this is the main objective of maintenance function. Here, maintenance has to provide the right reliability, availability, efficiency and capability to produce at the right quality for the production system, in accordance with the need for these characteristics.

- Ensuring the system or the plant life, refers to keeping systems in proper working condition, reducing chance of condition deterioration, and thereby increasing the system life.

- Ensuring human wellbeing or equipment shine has no direct economic or technical necessity but primarily a psychological one of ensuring the equipment or asset looks good.

- Ensuring safety refers to safety of production equipment and all engineering assets in general.

The asset lifecycle encompasses several dependent stages. Snitkin (2003) has an overview of all stages including planning for acquisition of new capital assets, acquisition of assets, installation, operation and maintenance and retire. Engineering assets generate value during this stage and demand care so that their best performance is maintained. This lifecycle stage involves management of asset information as well as the health and performance of the physical asset. Doing this efficiently requires considerable attention to labour and parts inventories. The need for collaboration among organizational processes affected by asset performance also peaks during this period. Due to the complexity, long process, and multiple stakeholders and departments involved in operations and maintenance, coordinating and sharing asset management data from all disparate sources into operational business intelligence requires many skills in intra-organization and inter-partner collaboration (Snitkin, 2003).

Collaboration requires individual and groups to communicate, coordinate, integrate and distribute work. This work can be done individually and then shared, potentially resulting in indirect collaboration, or done as a coordinated collaborative effort. These activities can be facilitated by people and integrated computer systems (Hardi and Whittaker, 2000).

Collaboration Technology in Engineering Asset Maintenance

Collaboration Technologies (CT) have been defined as technologies enabling individuals and groups to communicate, collaborate, and interact to share knowledge and information, focusing on those that facilitate dispersed interaction across time and/or space. Collaboration technology is designed to support two or more people to work cooperatively at the same place and time (synchronous) or at different places and/or different times (asynchronous) (Dennis et al., 1988; DeSanctis & Gallupe 1987).

Eden and Ackerman (2001) indicated several forms of collaboration technology that provide special benefits to users. Building on this theme, Knot et al. (2006); Dennis, Wixom, and Vandenberg (2001); Oslon, Malone and Smith (2001); DeSanctis and Gallupe (1987); Nunamaker et al. (1991); Zigurs and Buckland (1998); and Rein (1993), all concluded that generally, collaboration technology is a package of hardware, software, people, and/or processes that can offer one or more of the following:

- Enhance effectiveness of communication shared, awareness and decision quality, such as team performance efficiency in command and control;

- Support for communication among participants, such as electronic communication to augment or replace verbal communication;

- Information processing support, such as mathematical modelling or voting tools;

- Support to help participants adopt and use technology, such as agenda tools or real-time training;

- Support for organization design, such as developing a multi-user and computer-based environment.

Collaboration technologies enable members to communicate and collaborate as they deal with the opportunities and challenges of asset maintenance tasks (Massey, 2008). Collaboration technologies improve the efficiency and effectiveness of organizational work processes and decision making as well as reducing costs. Coupled by technology, dispersed knowledge workers across different divisions and functions, can provide input, share knowledge, negotiate, and coordinate work in the process of solving problems and making decisions.

Mobile Collaboration Requirements by Asset Maintenance’ Stakeholders

Jones (2006) argues that workers will perform their tasks at home, or go to a business as “corridor warriors”. Personal computers will not be replaced by mobiles, but mobile devices, according to Zuellig and Meckel (2008). For example, Smartphone and PDA and networks will be very centralized, will improve and accelerate work processes through timely provision of information, and better support the roles of communication and collaboration. Moreover, Smith (2005) states that each single organization uses a specific set of tools that is designated to support team collaboration to perform tasks in certain projects.

Through the development of mobile technologies, the processing of information can be performed by technical personnel away from the central production office or site. Maintenance personnel, when doing their tasks, require relevant information in different sites and need to communicate interactively with experts in the back office (Emmanoulidis, 2009). In regard to this task, Sinha et al. (2007) state that using mobiles allows maintenance personnel to continuously receive a daily schedule from the head office. This leads to the saving of time and improving customer service and profitability. Luff and Heath (1998) and Campbell et al. (2006) agree that mobility of special artefacts can enhance tasks and responsibilities. Hence, Emmanoulidis (2009) argues, in order to support maintenance task, the use of mobile collaboration technologies is a visible and effective approach. The maintenance task that can be supported by mobile collaboration technologies, are for example: information about machine state, process state, work orders and scheduling, a list of experts and their availability, condition monitoring and data diagnosis (Emmanouilidis, 2009).

Emmanoulidis (2009) explains that with reference to production machinery the right information and tools are present but they, typically, are not available at the right time, at the proper place or given to the right personnel. The advances made in mobile technologies can support technical personnel and maintenance experts to collaborate in different locations who are on the move. Such technology enables the availability of data/information and engineering tools anytime and anywhere to anybody. Furthermore, as stated by Emmanouilidis (2009), maintenance practice involves doing complex tasks such as maintenance planning, inspection, diagnostics, requires cooperation with another person. This collaboration is not the new but is a normal way in engineering industries. The availability of mobile collaboration technology in place makes a new perspective to support the asset maintenance action (Emmanouilidis, 2009). Maintenance activity that needs collaborative effort including inspection, monitoring, routine maintenance, overhaul, rebuilding, repair (Marquez, 2007), considered the MCT to be a necessity (Emmanouilidis, 2009).

In order to encounter good asset maintenance and meet the optimum performance of engineering assets, organisations require a collaborative teamwork within key functional areas (stakeholders) of the engineering organisations. Shared understanding, coordination, cooperation and collaboration across maintenance stakeholders of what asset maintenance is and how the entire maintenance team influence the ability to achieve organisational objectives through those assets are one of the critical success factors of asset management. Collaborative asset maintenance is applicable to all those who have a role in the maintenance of engineering assets including directors, managers, supervisor, engineers, IT and maintenance technicians.

Mobile collaboration technology required for asset maintenance need to be capable of simultaneously handling, processing and delivering technical and operational information to multiple maintenance crew at multiple locations at any time to enhance asset maintenance planning and implementation within the three levels of business activities. The requirements are including technological, organisational, as well as personal perspectives.

Research Methods

This research will be an interpretive study using both quantitative and qualitative methodologies. Klein and Myers (1999), Deetz (1996), and Orlikowski and Baroudi (1991) have reasoned that interpretive attempts to understand phenomena through the meanings that people assign to them are relevant. This understanding is particularly relevant in this research because the researcher is seeking to understand certain issues by industries survey, Delphi study and interviewing people on how mobile collaboration technologies will assist the asset maintenance process in a given organization’s context. In order to create a complete set of requirements of collaboration maintenance in engineering organizations, the case study results here will be triangulated with the survey, Delphi study and case study findings. Triangulation is the use of more than one research strategy to explore the same phenomenon so that the credibility of research results is improved (Greene, 1989).

The Delphi Technique

This study is conducted to identify collaboration requirements, current collaborative maintenance practice and mobile technology roles in support collaborative engineering asset maintenance. The Delphi technique is employed to more accurately build the consensus from the panel expert’s perception. The Delphi study is a group process to solicit expert responses toward reaching consensus on a particular problem, topic, or issue by subjecting them to a series of in-depth questionnaires, interspersed with controlled feedback (Dalkey & Helmer, 1963).

The Delphi method is employed for several reasons. The topic ‘Mobile collaboration technology in engineering asset maintenance’ is quite new, it is complex, a few literatures series have been found, and not much empirical data was available. Those are the reasons why Delphi study is useful to confront a mobile maintenance expert’s panel. Delphi study is carried out in this research which comprised three rounds (Linstone & Turoff 1975).

Multiple Case Studies

Semi-structured interview-based multiple case studies will be conducted to explore the collaboration requirements for asset maintenance practices, to obtain information on the deficiencies in existing collaboration requirements. These requirements refer to the current requirements concerning why mobile technologies are important to facilitate asset maintenance collaboration. Case study research provides the advantage of presenting a holistic view of a process (Yin, 2009). An in-depth investigation allows different aspects of a research topic and their relationships to be analysed (Markus, 1983). The primary goal of the case study is to examine the level of importance of the requirements, verify the Delphi findings, determine the ranking order of requirements of asset maintenance collaboration, identify the main requirements that need to be focused on and examine the relationships between the requirements (if any). Data gathered from the interviewees as responses to the research questions will be organized, stored and then analysed. In this case study, data obtained will be qualitative and therefore it will be analysed via qualitative data analysis, using NVivosoftware.

In order to create a complete set of requirements of collaboration maintenance in engineering organizations, the case study results here will be triangulated with the Delphi study findings. Triangulation is the use of more than one research strategy to explore the same phenomenon so that the credibility of research results is improved (Greene, 1989).

TOP Approach

Mitroff & Linstone (1993) argue that any phenomenon, subsystem or system needs to be analysed from what they call a Multiple Perspective method — employing different ways of seeing, to seek perspectives on the problem. These different ways of seeing are demonstrated in the TOP model of Linstone (1999) and Mitroff & Linstone (1993). The TOP model allows analysts to look at the problem context from either Technical or Organisational or Personal points of view:

- The technical perspective (T) sees organisations as hierarchical structures or networks of interrelationships between individuals, groups, organisations and systems. For Examples, science-technology, optimization, need validation, cause and effect etc.;

- The organisational perspective (O) sees the world through a different filter, from the point of view of affected and affecting organisations; and considers an organisation’s performance in terms of effectiveness and efficiencies. For examples, unique group or institutional view, reliance of experts, need SOP, institutional compatibility, etc.;

- The personal perspective (P) focuses on the individual’s concerns. For examples, learning, experience, prestige, intuition, need for certainty, etc.

Mitroff & Linstone (1993) suggest that these three perspectives can be applied as “three ways of seeing” any problems arising for, or within, a given phenomenon or system. Werhane (2002) further notes that the dynamic exchanges of ideas which is emerge from using the TOP perspectives are essential because they take into account “the fact that each of us individually, or as groups, organisations, or systems, creates and frames the world through a series of mental models, each of which, by it, is incomplete”. In other words, a single perspective on the problem context is not sufficient to elicit an insightful appreciation of it.

It is found that the collaborative maintenance requirements can be best described by using the TOP multiple-perspectives approach. Incorporation of technology-organisation-personal of collaborative maintenance requirements reflects the fact that the whole is more than the sum of its parts. In other words, using only one perspective is similar to seeing only a one-dimensional representation of a three-dimensional object.

Proposed Framework

In order to develop the mobile collaboration PAM framework, the research questions need to be answered. The major question is: How can mobile collaboration technologies assist asset maintenance in engineering asset management organization? Followed by four sub-questions:

Q1. What are the collaboration requirements in engineering management organizations for asset maintenance activities?

Q2. What is the existing state of collaboration technologies being used in engineering management organizations for asset maintenance activities?

Q3. What is the current role of mobile technologies in the above collaboration technologies?

Q4. What is the comprehensive framework for guiding the adoption and implementation of new mobile technologies that meet all maintenance collaboration requirements?

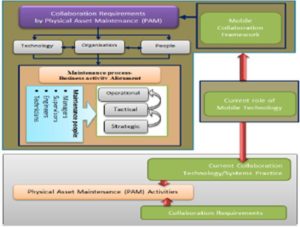

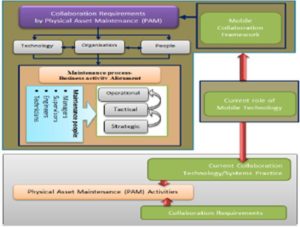

Based on the extensive literature review, a conceptual research framework was developed as shown in Figure 2. It encapsulates the core concept of Linstone’s (1999) TOP model as a means of studying collaboration requirements from either technical or organisational or personal perspectives. It also includes the alignment of maintenance processes with three levels of business activities: strategic, tactical and operational (Márquez, 2007).This conceptual framework will guide the planning and activities in the subsequent research for investigating collaboration requirements in physical asset maintenance.

Fig 1. Preliminary Maintenance Collaboration Framework

(Created by authors for this research guideline)

Framework Building

This phase of the research will build the mobile collaboration framework regarding asset maintenance in engineering organizations. The first phase reviewed the existing literature and prior theory in the relevant research areas, in order to formulate the research questions. A list of requirements and related information derived from the literature review will then be enhanced through Delphi study. This will be done to obtain an integrated, logically structured system of priority requirements, which will cover all the main requirements and the maintenance collaboration subsets in asset management. In order to create a complete set of requirements of collaboration maintenance in engineering organizations, the case study results will be triangulated with the Delphi study findings. Triangulation is the use of more than one research strategy to explore the same phenomenon so that the credibility of research results is improved (Greene, 1989). By using quantitative and qualitative approaches, this method provides a powerful means for analysis and interpretation of data (Sieber, 1973; Jick, 1979). Similarly, Smith (1975) argued that researchers can enhance the accuracy of their decisions by gathering different kinds of data on the same phenomenon.

Conclusion

It is expected that the research finding will build a unique framework addressing the following issues (1) business process alignment at all three levels (strategic, tactical and operational) in company activities through the variable of mobile collaboration technologies, (2) engineering asset management with a specific focus on the most critical process — asset maintenance, and (3) comprehensive framework that meet all requirements (technological, organisational and personal perspectives).

By implementing united management practice (maintenance process-business activity alignment) at the three levels, and adapting best practices of mobile collaborative maintenance from within and outside the maintenance stakeholders, engineering organisations will reach a maintenance management system that is simultaneously handling, processing and delivering technical and operational information to multiple maintenance crews at multiple locations at any time. In addition, it can enhance asset maintenance planning and implementation as well as continuously improved, and automatically adapts to the new and changing mobile technologies. This conceptual framework will guide the planning and activities of this research for identifying collaborative maintenance requirements in the perspectives of technology, organisation, and people.

References

Besten, M. D, Dalle, J. M. & Galia, F. (2006). “Collaborative Maintenance in Large Open-Source Projects,” International Federation for Information Processing, 23, 233-244.

Publisher – Google Scholar

Beurer-Zuellig, B. & Meckel, M. (2008). “Smartphones Enabling Mobile Collaboration,” Proceedings of the 41st Hawaii International Conference on System sciences, 7-10 January 2008, Waikoloa, HI, 1-10.

Publisher – Google Scholar

Camacho, J., Galicia, L., Gonzales, V. M. & Favela, J. (2008). “MobileSJ: Managing Multiple Activities in Mobile Collaborative Working Environments,” International Journal of e-Collaboration, 4 (1), 61-73.

Publisher – Google Scholar

Campbell, D. E., Sarker, S. & Valacich, J. S. (2006). “Collaboration Using Mobile Technologies (MCTs): When is it Essential?,” Proceedings presented at The International Conference on Mobile Business (ICMB), 26-27 June 2006, Washington State University, Pullman, WA, 12-19.

Publisher – Google Scholar

Dalkey, N. & Helmer, O. (1963). “An Experimental Application of the Delphi Method to the Use of Experts”, Management Science, 9, 458-467.

Publisher – Google Scholar

Deetz, S. (1996). “Describing Differences in Approaches to Organization Science: Rethinking Burrell and Morgan and their Legacy,” Organization Science, 7 (2), 191-207.

Publisher – Google Scholar

Dennis, A. R., George, J. F., Jessup, L. M., Nunamaker, J. F. & Vogel, D. R. (1998). ‘Information Technology to Support Electronic Meeting,’ MIS Quarterly, 2 (4), 591-624.

Google Scholar

Dennis, A. R., Wixon, B. H. & Vanderberg, R. J. (2001). “Understanding Fit and Appropriation Effects in Group Support Systems via Meta-Analysis,” MIS Quarterly, 25 (2), 167-197.

Publisher – Google Scholar

Desantic, G. & Gallupe, R. B. (1987). “A Foundation for the Study of Group Decision Support Systems,” Management Science, 33 (5), 589-609.

Publisher – Google Scholar

Duffua, S. O. & Al-Sultan, K. S. (1999). “A Stochastic Programming Model for Scheduling Maintenance Personnel,”Applied Mathematic Modelling, 23 (5), 385-397.

Publisher – Google Scholar

Emmanoulidis, C., Liyanage, J. P. & Jantunen, E. (2009). “Methodology and Theory: Mobile Solution for Engineering Asset and Maintenance Management,” Journal of Quality in Maintenance Engineering’, 15 (1), 92-105.

Publisher – Google Scholar

Hodkiewicz, M. R. & Pascual, R. (2006). “Education in Engineering Asset Management-Current Trends and Challenges,”Presented at The International Physical Asset management Conference, 28-31 May 2006, Teheran.

Publisher – Google Scholar

Jones, N. (2006). ‘Europeans Expect Mobile Technology to Facilitate Collaboration in 2009,’ Gartner Research Publication. [Online], [Retrieved September 10, 2011],

http://my.gartner.com/portal/server.pt?open=512&objID=260&mode=2&PageID=3460702&resId=497329&ref=QuickSearch

&sthkw=Europeans+expect+mobile+technology+to+facilitate+collaboration+in+2009

Knott, B. A., Bolia, R. S., Nelson, W. T. & Galster, S. M. (2006). “Effects of Collaboration Technology on the Performance of Tactical Air Battle Management Teams,” Proceedings of the Human Factors Issues in Network-Centric Warfare TTCP Symposium, Sydney, Australia.

Publisher – Google Scholar

Laszkiewics, M. (2003). “Collaborative Maintenance: A Strategy to Help Manufactures Become Learn, Mean, and Agile,”Plant Engineering, 57 (9), 30-36.

Publisher – Google Scholar

Linstone, H. A. (1999). “Decision Making for Technology Executives: Using Multiple Perspectives to Improve Performance,” Artech House Publisher, London.

Publisher – Google Scholar

Linstone, H. A. & Turoff, M. (1975). ‘The Delphi Method: Techniques and Applications,’ Addison-Wesley, London.

Google Scholar

Luff, P. & Heath, C. (1998). “Mobility in Collaboration,” In Proceedings of the CSCW, ACM Press, New York, 305—314.

Publisher – Google Scholar

Márquez, A. C. (2007). ‘The Maintenance Management Framework,’ Springer-Verlag, London.

Massey, A. P. (2008). “Collaborative Technologies,” Book Chapter, Department of Operations, Decision and Information Technologies, Indiana University, Bloomington, IN, USA, 341 — 354.

Publisher – Google Scholar

Mitroff, I. I. & Linstone, H. A. (1993). ‘The Unbounded Mind: Breaking the Chains of Traditional Business Thinking,’OxFord University Press, New York.

Google Scholar

Nunamaker, J. F., Dennis, A. R., Valacich, J. S., Vogel, D. & George, J. F. (1991). “Electronic Meeting Systems to Support Group Work,” Communication of the ACM, 34 (7), 40-61.

Publisher – Google Scholar

Olszwesky, R. (n.d.). “RCM Success Starts with CMMS,” [online], [Retrieved September 10, 2011],http://www.maintenanceworld.com/Articles/reliabilityweb/RCM_Success_CMMS.pdf.

Publisher

Oslon, G. M., Malone, T. W. & Smith, J. B. (2001). Coordination Theory and Collaboration Technology, Lawrence Erlbaum Associates, Publisher, New Jersey, London.

Publisher – Google Scholar

Pintelon, L. & Muchiri, P. N. (2009). “Safety and Maintenance,” Handbook of Maintenance Management and Engineering, ISBN 1848824718, 613-648.

Publisher – Google Scholar

Rein, G. L. (1993). ‘Collaboration Technology for Organizational Design,’ Proceedings of the 26th Hawaii International Conference, 5-8 January 1993, Hawaii, 137-148.

Google Scholar

Romero, D., Galeano, N. & Molino, A. (2008). “Readiness for Collaboration Assessment Approach in Collaborative Networked Organisations,” IFIP International Federation for Information Processing, 266, 47-56.

Publisher – Google Scholar

Richey, R. G. & Autry, C. W. (2009). ‘Assessing interfirm Collaboration Technology Investment Trade-Offs: The Effects of Technological Readiness and Organizational Learning,’ International Journal of Logistics Management, 20 (1), 30-56.

Sinha, A, Lahiri, R. N., Chowdhury, S., Chowdhury, S. P. & Song, Y. H. (2007). “Complete IT Solution for Enterprise Asset Management (EAM) in Indian Power Utility Business,” Presented at the 42nd International Conference of Universities Power Engineering, UPEC, 4-6 September 2007, Mumbai, 645-650.

Publisher – Google Scholar

Smith, D. M. (2005). “Team-based Collaboration Technologies are Pieces of a Puzzle,” Gartner Research. [online], [Retrieved January 15, 2012], http://www.gartner.com/technology/research.jsp.

Publisher

Snitkin, S. (2003). ‘Collaborative Asset Lifecycle Management Vision and Strategies,’ Research Report, ARC Advisory Group, Boston.

Google Scholar

Tam, A. S. B. & Price, J. W. H. (2006). “Optimisation Framework for Asset Maintenance Investment,” Monash Business Review, 2 (3), 1-10.

Publisher – Google Scholar

Tsang, A. H. C. (2002). “Strategic Dimension of Maintenance Management,” Journal of Quality in Maintenance Engineering, 8 (1), 7-39.

Publisher – Google Scholar

Werhane, P. H. (2002). “Moral Imagination and Systems Thinking,” Journal of Business Ethics, 38, 33-42.

Publisher – Google Scholar

Zhang, Z., Li, Z. & Huo, Z. (2006). “CMMS and its Application in Power System,” International Journal of Power & Energy Systems, 26 (1), 75-82.

Publisher – Google Scholar

Zigurs, I. & Buckland, B. K. (1998). ‘A Theory of Task/Technology Fit and Group Support,’ Management Information system research Centre, University of Minnesota, 22 (3), 313-334.