Introduction

Supply Chain Management (SCM) is an effective business philosophy that has gained a tremendous amount of attention from academics, consultants, practitioners and business managers in the recent years in order to help enterprises survive under continuous pressures and achieve the common goal of enhanced customer satisfaction. Over the last decade of evolution of SCM, a steady stream of researches dealing with supply chain performance measurement (SCPM) has been published. As an indispensable management tool and the vehicle to achieving success, performance measurement enables supply chain to strategically manage and continuously control achieving of objectives. It provides the necessary assistance for performance improvement in pursuit of supply chain excellence.

In this paper, we focus on the studies and articles published on SCPM. The paper’s primary concern is not just the advancements in theory in the field, but rather to contribute in providing taxonomy for mapping and evaluation of researches conducted under this topic according to the criteria of measurement. Such taxonomy is believed to be needed as an aid to both: classification of research in the field and as a means of providing a framework for the identification of key content of the subject. The main purposes of this study are as follows:

- Review the literature available on SCPM. Highlight strengths and limitations of existing frameworks;

- Present a framework for classification and analysis;

- Identify the possible gaps and pose future research directions accordingly.

The rest of this paper is organized as follows: Section 2 is an introductory overview of SCPM in which important definitions are provided. In section 3, the evolution of supply chain performance measurement topic is discussed. Then in section 4, the common frameworks and approaches available in literature for this purpose are classified into nine different groups and demonstrated in terms of history, criteria of measurement, advantages and drawbacks. And in section 5, further analysis and exploration are reported and insights from the conducted review are illustrated and discussed. Finally in section 6, summary, conclusion and possible extensions of the currently existing approaches are provided.

Supply Chain Performance Measurement

Performance measurement is generally defined as the process of quantifying the efficiency and effectiveness of action (Neely et al., 1995). Effectiveness is the extent to which customer’s requirements are met, while efficiency measures how economically a firm’s resources are utilized to achieve a predetermined level of customer satisfaction. Based on Neely et al.’s assertions (Neely, 1998; Neely, 2005), only when you can measure something and express it in numbers, you have good background and knowledge about it. Otherwise, your knowledge about it is limited and unsatisfactory. According to Bhagwat and Sharma (2007), performance measurement describes the feedback on operations which are geared towards customer satisfaction, strategic decisions and objectives. They further point out that performance measurement reflects the need for improvement in operational areas which are referred to as bottlenecks in performance measures.

Performance measurement is an important aspect of successful SCM. Gunasekaran et al. (2001) described effective performance measurement as necessary for SCM. Lai et al. (2002) further asserted that the lack of adequate performance measurement is one of the major obstacles to efficient SCM. According to Abu-Suleiman et al. (2004), the importance of performance measurement systems can be summarized in the following reasons:

a. Drive Organizational Actions

Performance measurement drives actions in two respects: First, monitored measures get high visibility within an organization and people strive to achieve high performance with respect to these measures. Second, measured metrics drive actions by identifying areas of improvement. Once identified poor, management should take corrective actions to address such issues.

b. Framework for Decision Making

Measurement provides basis to evaluate alternatives and set decision criteria. The structure of the measurement system drives decisions and actions at the strategic, tactical and operational levels. Hence, a relevant performance management system targets optimizing the performance across multiple objectives.

c. Closed Loop Control

Feedback is an integral part of any process. An effective performance management system provides necessary feedback information to reveal progress, diagnose problems, identify potential opportunities for improvement, facilitates inter-understanding and communication among supply chain members and tests the effect of different strategies.

Holmberg (2000) and Eccles and Pyburn (1992) define SCPM as a system that provides a formal definition of supply chain performance model based on mutually agreed on goals, metrics and measurement methods that specify procedures, responsibilities and accountability of supply chain participants and the regulation of the system by them.

As the vehicle to organizational change, the design and development of a SCPM system is a critical issue. It has been tackled and discussed in numerous researches in which authors and experts in the field suggested various desirable characteristics. However, they all (Beamon, 1999; Keebler, 2001; Gunasekaran et al., 2004; Tangen,, 2004; Ramaa et al., 2009; Akyuz, and Erkan, 2010; Kurien and Qureshi , 2011) agreed that an effective SCPM system should be characterized by:

- Inclusiveness: Covers all aspects and processes of a supply chain

- Universality: Allows for comparison under different operating conditions

- Measurability: Output is quantitative and can be measured

- Consistency: Metrics are compatible with supply chain goals

The selection of right performance metrics is another crucial issue. The appropriate measures do not only offer a means of tracking how far an organization is from achieving its objectives, but also provide a means of communicating strategy and encouraging its implementation.

Several researchers have addressed this problem and discussed the features and requirements of appropriate measures (Lai et al., 2002;, Beamon, 1999; Keebler, 2001; Gunasekaran et al., 2004; Parker, 2000; Lapide, 2000; Chan and Qi, 2003; Chan, 2003; Simchi-Levi et al., 2002; Basu, 2001; Beamon and Ware, 1998; Bourne et al., 2000; Bourne et al., 2002; Dasgupta , 2003; De Toni and Tonchia, 2001; Gunasekara et al., 2005; Gunasekaran, and Kobu, 2007; Harrison and New, 2002; Kaplan and Norton, 2006; Kennerley and Neely, 2002; Kennerley and Neely, 2003; Kim, 2006; Kleijnen and Smits, 2003; Koh et al., 2007; Landeghem and Persoons, 2001; Li et al.,2005; Li et al., 2007; Lummus et al.,2003; Maskell, 1992; Martinez and Kennerley, 2005; Melynk et al., 2004; Najmi et al.,2005; Petroni and Panciroli , 2002; Ren , 2008; Sahay, 2006; Shepherd and Gunter , 2006; Stewart, 1995; Suwignjo et al., 2000; Talluri and Sarkis , 2002; Tian et al., 2003 ; Vereecke and Muylle , 2006; Zhaofang et al., 2006; Venkata,, 2007; Öztaysi and Uçal,, 2009; Agami et al., 2011.; Cirtita and Glaser-Segura, 2012; Tan et al., 2011; Hall and Saygin, 2012; Agarwal and Shanka, 2005; Sarode et al., 2009). They stated that performance measures have to be measurable, non-conflicting and clearly defined across the chain along with many other characteristics. Gunasekaran et al. (2004) for instance, have recently emphasized that supply chain performance measures should mainly be balanced (financial vs. non-financial) and should be classified at the strategic, tactical and operational management levels.

Evolution of SCPM

As stated earlier, measurement is important as it directly affects the behavior that impacts supply chain performance. Thus, SCPM provides the means by which a company can assess whether its supply chain has improved or degraded. Both quantitative and qualitative performance indicators were put forward. However, to track and measure their performance, companies traditionally relied solely on financial accounting metrics, many of which date back to the 19th century and even earlier. At that time, performance measures were in the form of: cost per yard, cost per metric ton and so on. Then at the beginning of the 20th century, diversification induced the reformation of performance measurement, and DuPont Company in 1903 had executed the “Rate of Return on Investment” (ROI) to appraise the performance of different units and developed the “DuPont System Scale” which was widely adopted afterwards. Since then, financial indicators became systematic (Parker, 2000). After World War II, the nature of the environments surrounding enterprises changed and became full of uncertainty and variation which called for the necessity to balance the relations of marketing, research and development, human resources and finance (Kurien and Qureshi, 2011). Hence, companies shifted their priorities and started to use financial and non-financial indicators, i.e., the mixed approach.

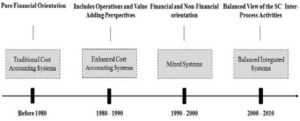

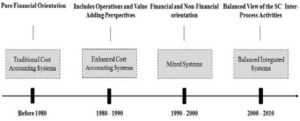

With the evolution and maturity of business organization concept in the late 1990s, performance measurement systems have changed completely to balanced integrated approach (Parker, 2000). Figure 1 illustrates the evolution of SCPM systems on a timeline that is split into four eras.

Before the 1980s, traditional cost accounting systems with pure financial orientation were used. They relied solely on generic quantitative financial metrics, ignoring any other important strategic none financial ones such as customer loyalty or service quality. In the first decade afterwards, those cost accounting systems were enhanced whereby the scope of financial indicators extended to cover different functions and specific operations within the supply chain. In the early 1990s, Kaplan and Norton (1992) developed the Balanced Scorecards (BSC) approach which constituted the introduction of the mixed systems concept for the first time. Their approach addressed explicitly the importance of monitoring and evaluating none-financial indicators as well. During the last decade, integrated online systems concept as well as e-commerce has strongly been evolving in an attempt to enable information sharing and facilitate the whole measurement process across the different supply chain perspectives.

Fig 1. SCPM Evolution Timeline

Financial measures are critically important in assessing whether or not operational changes are improving the financial health of an organization. However, as highlighted and emphasized in literature (Kurien and Qureshi, 2011; Lapide, 2000), they are insufficient to measure supply chain performance for the following reasons:

- They tend to be short-term, internally focused and historically oriented,

- They do not relate to important strategic, non-financial performance indicators such as customer satisfaction and product quality,

- They do not directly tie to operational effectiveness and efficiency.

In response to the deficiencies of traditional accounting methods for measuring the performance of supply chains, a variety of measurement systems and approaches have been developed as discussed comprehensively in the next section.

Common SCPM Frameworks: Review and Classification

The literature on SCPM is relatively huge (Ramaa et al., 2009; Akyuz and Erkan, 2010; Kurien and Qureshi, 2011; Estampe and Lamouri , 2011; Lauras et al., 2011). Several attempts have been made to measure supply chain performance using conventional approaches. Surveying the literature revealed that there are generally two classes of SCPM systems: Financial and Non-financial. Each class is explained in details below.

Financial Performance Measurement Systems (FPMS)

Financial performance measurement systems are generally referred to as traditional accounting methods for measuring supply chain performance. They mainly focused on financial indicators and hence were always criticized for being inadequate because they ignore important strategic non-financial measures as explained in the previous section. In literature (Lapide, 2000), two FPMS methods highlighted as very popular are:

Activity-Based Costing (ABC)

The ABC approach was developed in 1987 by Kaplan and Bruns (1987) in attempt to tie financial measures to operational performance. It involves breaking down activities into individual tasks or cost drivers while estimating the resources, such as time and costs, needed for each one. Costs are then allocated based on these cost drivers rather than on traditional cost accounting methods such as allocating overhead either equally or based on less relevant cost drivers. The approach was designed in such a way to allow for better assessment of the true productivity and costs of a supply chain process. However, it still suffered the major limitation of relying only on pure financial metrics.

Economic Value Added (EVA)

The EVA is an approach for estimating a company’s return on capital or economic value added. It was developed in 1995 by Stern et al. (1995) in order to correct the deficiency of traditional accounting methods which focused only on short-term financial results providing little insights into the success of an enterprise towards generating long-term value to its shareholders. EVA approach is based on the premise that the shareholder’s value is increased when a company earns more than its cost of capital. The EVA measure attempts to quantify the value created by an enterprise basing it on operating profits in excess of capital employed (through debt and equity). Though useful for assessing high level executive contributions and long-term shareholder value, EVA metrics fail to reflect operating supply chain performance since it only considers pure financial indicators.

Non-Financial Performance Measurement Systems (NFPMS)

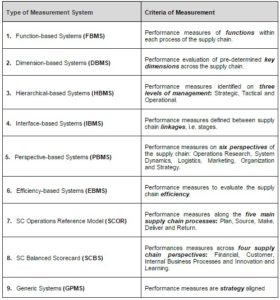

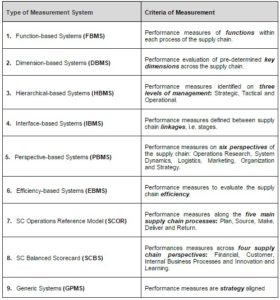

Upon reviewing the literature in the field of SCPM (Ramaa et al., 2009; Akyuz and Erkan, 2010; Kurien and Qureshi, 2011; Estampe and Lamouri, 2011; Lauras et al., 2011; Cuthbertson and Piotrowicz, 2011), the researchers believe that currently available non-financial SCPM approaches can be classified into nine different types grouped according to their criteria of measurement. Very few attempts (Ramaa et al., 2009) were made earlier for the same purpose but were narrower in scope, limited to certain approaches and didn’t provide a clear comparison that demonstrates the key differences between groups. The identified groups are discussed in the next nine sub-sections.

Supply Chain Balanced Scorecard (SCBS)

In 1992, Kaplan and Norton (1992) introduced the Balanced Scorecard (BSC) as an indispensible performance management tool. Since then, it has been recognized as the leading tool for performance measurement in both research and industry. It enables managers to observe a balanced view of both operational and financial measures at a glance. The authors proposed four basic perspectives that managers should monitor as follows: Financial, Customer, Internal Business Processes and Innovation and Learning perspectives. A graphical illustration can be found in Kaplan and Norton (1992). Bearing these four perspectives in mind, managers can translate strategies into specific measures that can monitor the overall impact of a strategy on the enterprise.

The goals and measures in each perspective are extracted from the enterprise strategy. Brewer and Speh (2000) demonstrate how a supply chain management framework is linked to the balanced scorecard.

BSC is powerful in providing managers with a comprehensive picture of the enterprise performance (Abu-Suleiman et al., 2004; Kaplan and Norton, 1992). However, it suffers two basic limitations as discussed in literature. First, it is a top-down approach. Therefore, it is not participative and might fail to detect existing interactions between different process metrics. According to Lohman et al. (2004), BSC is a static approach which when applied in corporate setting does not provide an opportunity to develop, communicate and implement strategy. Second, although powerful and widely used in industry, BSC provides a conceptual framework only. That is, it lacks an implementation methodology and thus deviates from the merit of concept itself.

Supply Chain Operations Reference Model (SCOR)

SCOR model was created by the Supply Chain Council (Stephens, 2001; Huang et al., 2004; Lockamy and McCormack, 2004). The first version was developed in 1996. It is a framework for examining the supply chain in detail through defining and categorizing the processes that make up the chain, assigning metrics to such processes and reviewing comparable benchmarks. The SCOR model framework can be found in Huang et al. (2004). It is the only integrated cross-functional framework that links performance measures, best practices and software requirements to a detailed business process model.

The SCOR model defines a supply chain as being composed of five main integrated processes: Plan, Source, Make, Deliver and Return. Performance of most processes is measured from 5 perspectives: Reliability, Responsiveness, Flexibility, Cost and Asset. As the model spans the chain from supplier’s supplier to customer’s customer aligned with operational strategy, material, work and information flows, it is considered an exhaustive system that requires a well-defined infrastructure, fully dedicated managerial resources and continuous business process re-engineering to align the business with best practices.

Dimension-based Measurement Systems (DBMS)

DBMS concept is based on the premise that any supply chain can be measured on dimensions (Ramaa et al., 2009). Initially in 1999, Beamon (1999) identified three types of measures as necessary components in supply chain performance measurement systems, namely: Resources (R), Output (O) and Flexibility (F). She believed that each of these types is vital to reflect the overall performance success of a supply chain and that the result of each type affects the others.

Examples of resource performance measures are manufacturing cost, inventory cost and return on investment (ROI). Output measures include total sales, on-time deliveries and fill rate, whereas flexibility measurements measure volume changes and new product introduction.

Another example of DBMS is that identified by Hausman (2003) who suggests that a supply chain needs to perform well on three key dimensions: Service, Assets and Speed. Service related to the ability to anticipate, capture and fulfil customer demands. Assets involve anything with financial value such as inventory and cash, while speed includes metrics that are time-related to track responsiveness and velocity of execution. DBMS are generally simple, flexible and easy to implement; however, they don’t reflect the performance of internal functions and operations within the chain since they only focus on top level measures.

Interface-based Measurement Systems (IBMS)

IBMS was primarily put forward in 2001 by Lambert and Pohlen (2001). They proposed a framework in which performance of each stage is linked within the supply chain. The framework begins with the linkages at the focal company and moves outward one link at a time. This link by link approach provides a means for aligning performance from point of origin to point of consumption with the overall objective of maximizing the shareholder value for the entire supply chain as well as for each individual company. The IBMS approach theoretically looks good but in actual business setting, it requires openness and total sharing of information at every stage which is eventually difficult to implement (Ramaa et al., 2009).

Perspective-based Measurement Systems (PBMS)

PBMS look at the supply chain in all possible perspectives and provides measures to evaluate each of them (Ramaa et al., 2009). They were developed in 2003 by Otto and Kotzab (2003) who identified six main perspectives as follows: System Dynamics, Operations Research, Logistics, Marketing, Organization and Strategy. The authors presented six unique sets of metrics, one for each perspective, to measure performance of supply chains.

An example of a PBMS is the Logistics Scoreboard (Lapide, 2000) in which recommended performance measures focus only on logistical aspects of the supply chain. They fall into the following general categories: logistics financial performance measures (ex: expenses and return on assets), logistics productivity measures (ex: orders shipped per hour), logistics quality measures (ex: shipment damage) and logistics cycle time measures (ex: order entry time).

PBMS provides different vision to evaluate the supply chain performance. However, there might be a trade-off between measures of one perspective with measures of other perspectives.

Hierarchical-based Measurement Systems (HBMS)

In 2004, Gunasekaran et al. (2004) developed HBMS in which measures are classified as strategic, tactical or operational. The main idea was to assign measures where they can be best dealt with by the appropriate management level, thus facilitating quick and appropriate decisions (Ramaa et al., 2009). The metrics are further distinguished as financial or non-financial. Such systems tie together the hierarchical view of supply chain performance measurement and maps the performance measures specific to organization goals. However in such systems, a clear guide cannot be made to put the measures into different levels that can lead to reduced levels of conflict among the different supply chain partners.

Function-based Measurement Systems (FBMS)

FBMS is one in which measures are combined to cover the different processes in a supply chain (Ramaa et al., 2009). It was originally developed in 2005 by Christopher (2005) to cover the detailed performance measures applicable at different linkages of the supply chain. Though easy to implement and targets can be dedicated to individual departments, it does not provide top level measures to cover the entire supply chain. FBMS are generally criticized for viewing the separate supply chain functions in isolation with the overall strategy and hence results in localized benefits that may harm the whole supply chain.

Efficiency-based Measurement Systems (EBMS)

EBMS are systems that measure the supply chain performance in terms of efficiency. Several approaches were developed in this context (Ramaa et al., 2009; Chan and Qi, 2003; Chan, 2003; Charan, et al., 2007; Sharma and Bhagwa, 2007; Chen and Paulraj, 2004]. Wong and Wong (2007) provided a framework to study supply chain performance by developing a Data Envelopment Analysis (DEA) model for the internal supply chain performance efficiency using case study applications.

Chen et al. (2006) investigated the efficiency existing between two supply chain members. They proposed several DEA-based supply chain efficiency functions aimed at identifying the inefficiency among the chain members by developing two efficiency functions. They established the existence of several Nash1 equilibriums in the supplier-manufacturer game.

1 Nash equilibrium is a solution concept in game theory proposed by John Nash. For any game involving two or more players, a Nash equilibrium exists when each player is assumed to know the equilibrium strategies of the other players, and no player has anything to gain by changing only his own strategy unilaterally.

Liang et al. (2006) developed a new DEA-based approach to measure the supply chain efficiency when intermediate measures are built into the evaluation scheme. It aimed at correcting the inadequacies of the conventional DEA model when evaluating multi-member supply chain operations directly. Berrah and Cliville (2007) developed a framework which linked elementary performance expression to the overall performance of a supply chain. Aggregation was done using the Choquet integral Operator. Their approach allowed for the comparison of situations conventionally considered incomparable.

Most of the EBMS are DEA-based. Despite being very useful, they suffer the main limitations of the conventional DEA approaches in any other context. The efficiency measured is only a relative one. It determines the efficiency of different units within the supply chain relative to each other and not versus a previously set target value or a best practice. This might sometimes be misleading to managers and stakeholders.

Generic Performance Measurement Systems (GPMS)

Since the early 1980s, a number of generic performance measurement models and frameworks, i.e. not necessarily specific to supply chains, have been developed. Each of which has its respective benefits and limitations. However, the literature review indicates that only very few of them (Tangen,, 2004; Kurien and Qureshi , 2011) are widely cited and referred to as discussed below.

i. Performance Prism

The performance prism is a performance measurement framework that suggests performance should be measured across five distinct, but linked, perspectives of performance as indicated by Neely et al. (2001): stakeholder satisfaction, strategies, processes, capabilities and stakeholder contributions.

The performance prism has a much more comprehensive view of different stakeholders than other frameworks. The major strength of this conceptual framework is that it first questions the company’s existing strategy before the process of selecting measures is started. Hence, it ensures that the performance measures have a strong foundation.

The performance prism also considers new stakeholders (such as employees, suppliers, alliance partners or intermediaries) who are usually neglected when forming performance measures. Although the performance prism extends beyond traditional performance measurement, a main drawback is that it offers little about how the performance measures are going to be identified and selected (Tangen, 2004; Kurien and Qureshi , 2011).

ii. Performance Pyramid

The purpose of the performance pyramid is to link an organization’s strategy with its operations by translating objectives from the top down (based on customer priorities) and measures from the bottom up (Kurien and Qureshi , 2011; Lynch and Cross, 1991). This framework includes four levels of objectives that address an organization’s external effectiveness (left side of the pyramid) and its internal efficiency (right side of the pyramid) as demonstrated in Tangen (2004). The development of a company’s performance pyramid starts with defining an overall corporate vision at the first level, which is then translated into individual business unit objectives. The second-level business units are short-term targets of cash flow and profitability and long-term goals of growth and market position. The business operating system bridges the gap between top-level and day-to-day operational measures such as customer satisfaction, flexibility and productivity. Finally, four key performance measures: quality, delivery, cycle time and waste, are used at departments and work centers on a daily basis.

Ghalayini and Noble (1996) suggest that the main strength of the performance pyramid is its attempt to integrate corporate objectives with operational performance indicators. However, this approach also does not provide any mechanism to identify key performance indicators, nor does it explicitly integrate the concept of continuous improvement.

iii. Medori and Steeple’s Framework

In 2000, Medori and Steeple (2000) developed and presented an integrated framework for auditing and enhancing performance measurement systems. The graphical framework of their approach is presented in Medori and Steeple (2000). It consists of six detailed stages. Similar to most frameworks, the starting point begins with defining the company’s manufacturing strategy and success factors. In the next stage, the primary task is to match the company’s strategic requirements from the previous stage with competitive priorities. Then, the selection of the most suitable measures takes place in the following stage. After the selection of measures, the existing performance measurement system is audited to identify which existing measures will be kept. An essential activity is the actual implementation of the measures. The last stage is based around the periodic review of the company’s performance measures. An important advantage is that it can be used both to design a new system and to enhance an existing one. It also contains a unique description of how performance measures should be selected. Its limitations are mainly located in the second stage, where a performance measurement grid is created in order to give the system its basic design. Little guidance is given in this stage and the grid is only constructed from six competitive priorities whereas performance measures can be divided into many other categories (Kurien and Qureshi, 2011; Medori and Steeple, 2000).

In an earlier literature survey on SCPM, Ramaa et al. (2009) have previously classified SCPM systems into seven distinct types. However in this review, other two novel groups are added to their classification, namely: EBMS and GPMS. The first refers to the performance measurement systems that aimed at measuring the efficiency of supply chains and groups them into one category, while the latter is composed of the common performance measurement frameworks available in literature that can be used for SCPM, however not specifically developed for this purpose. Exceptionally excluding the BSC which Ramaa et al. (2009) considered as one distinct category because of the numerous researches conducted on its use for SCPM. A summary of the Non-Financial Performance Measurement Systems (NFPMS) with their criteria of measurement is given in Table 1.

Table 1 – Summary of NFPMS and Their Criteria of Measurement

As discussed in this section, several methods and frameworks have been developed for measuring supply chain performance. However, contributions of the majority of the existing performance measurement systems in SCM context are discounted by the existence of too many limitations that can be highlighted and summarized as follows (Bhagwat and Sharma., 2007; Akyuz, and Erkan, 2010; Lapide, 2000; Estampe and Lamouri , 2011; Chan and Qi, 2003; Chan, 2003; Van and Remko, 1998; Tracey and Tan, 2001; Simchi-Levi et al., 2002; Bernard and Gianni , 2003; Ren et al., 2004; Fynes et al., 2005; Saad and Patel, 2006; Fabbe-Costes and Jahre, 2007):

- Not connected with strategy;

- Incompleteness and inconsistencies in performance metrics;

- Lack of balanced approach that incorporates financial and non-financial measures;

- Lack of holistic approach, i.e. a supply chain must be viewed as one whole entity and measured widely across the whole;

- Being static and short-term, profit-oriented;

- Encourages local optimization and thus, fails to support continuous improvement.

- Being too inward looking;

- Insufficient focus on customers and competitors; and

- Large number of metrics, making it difficult to identify critical few among trivial many.

The previous deficiencies clearly illustrate the problems of today’s performance measurement systems. With all these problems highlighted, there seems to be no universal consensus regarding the definition of appropriate SCPMS; and commonly implemented ones are still, to a great extent, fragmented. Many of them lack strategy alignment, a balanced approach and systems thinking and thus have difficulty in systematically identifying the most relevant metrics (Akyuz, and Erkan, 2010).

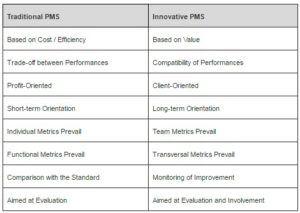

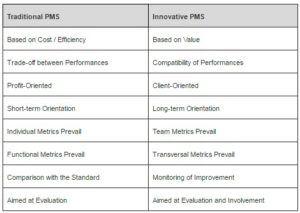

In the work done by Cai et al. (2009), they also state that current SCPM systems do not provide definite cause-effect relationship among numerous hierarchical individual performance indicators. The fact that such systems are static is also mentioned and emphasized. McCormack et al. (2008) compare the traditional and innovative Performance Measurement Systems (PMS) as outlined in Table 2 highlighting the necessary changes over traditional ones.

Table 2 – Traditional Vs. Innovative PMS

Several studies also emphasized the need for determining the right type of metrics that clearly reflect the true performance of the supply chain (Lai et al., 2002;, Beamon, 1999; Keebler, 2001; Gunasekaran et al., 2004; Parker, 2000; Lapide, 2000; Chan and Qi, 2003; Chan, 2003; Simchi-Levi et al., 2002; Basu, 2001; Beamon and Ware, 1998; Bourne et al., 2000; Bourne et al., 2002; Dasgupta , 2003; De Toni and Tonchia, 2001; Gunasekara et al., 2005; Gunasekaran, and Kobu, 2007; Harrison and New, 2002; Kaplan and Norton, 2006; Kennerley and Neely, 2002; Kennerley and Neely, 2003; Kim, 2006; Kleijnen and Smits, 2003; Koh et al., 2007; Landeghem and Persoons, 2001; Li et al.,2005; Li et al., 2007; Lummus et al.,2003; Maskell, 1992; Martinez and Kennerley, 2005; Melynk et al., 2004; Najmi et al.,2005; Petroni and Panciroli , 2002; Ren , 2008; Sahay, 2006; Shepherd and Gunter , 2006; Stewart, 1995; Suwignjo et al., 2000; Talluri and Sarkis , 2002; Tian et al., 2003 ; Vereecke and Muylle , 2006; Zhaofang et al., 2006; Venkata,, 2007; Öztaysi and Uçal,, 2009; Agami et al., 2011.; Cirtita and Glaser-Segura, 2012; Tan et al., 2011; Hall and Saygin, 2012; Agarwal and Shanka, 2005; Sarode et al., 2009).They attempted to outline and describe different performance measures across and between organizations using various approaches, such as simulation, (spreadsheet, system dynamics, discrete-event and business games), Balanced Scorecards (BSC), Fuzzy Logic (FL), mathematical modeling (DEA, linear programming and multi-attribute decision making methods) (Chan and Qi, 2003; Wong and Wong , 2007; Venkata,, 2007; Öztaysi and Uçal, 2009; Agami et al., 2011; Ainapour et al., 2011; Sobrino et al., 2011) and empirical studies.

With the aforementioned flaws, an effective SCPM method remains under considerable debate and requires further research and exploration (Marwah et al., 2012).

Analysis and Suggested Research Directions

Throughout the previous section, the researchers reviewed and classified the available literature under the topic of SCPM into nine different groups. In order to achieve that objective, a database containing the bibliographical sources consulted was created. Two methods were used to identify citations: First, using abstracting and online services. And second, through citation search in existing journals, conferences, working papers and theses. The reference list to this paper includes more than 100 references constituting the publications examined. However in this section, the researchers attempt to further explore and analyze the different methods and frameworks explained in the complementary bodies of literature under the topic of SCPM. The papers were analyzed according to two criteria:

- Methodology Type: Be it theoretical or empirical as originally devised by Croom et al. (2000)

- Nature of the Framework: Where it can be categorized on two dimensions: Time and Level. The former indicates whether the measurement framework is dynamic or static, whereas the latter represents the level on which performance is measured. It can either be the entity level (individual organization) or the system level (the whole supply chain).

Methodology Type – Criterion:

In order to understand the theory development in SCPM, the literature under this topic had to be analyzed and classified. In accordance, the approach devised earlier by Croom et al. (2000) that suggested categorizing the literature as theoretical or empirical was followed. To the researchers’ knowledge, this classification is novel in the domain of SCPM. It represents a form of literature analysis with which most researchers are familiar. However, the distinction here is for the topic under which literature is classified, i.e., SCPM. The researchers differentiate between theoretical works which set out to define scientific concepts, provide explanations or propose new frameworks structure and empirical works which focus on reporting practices and real life applications. The main concern is to understand and analyze the development of research on SCPM and hence, identify opportunities for further advancements in this research direction.

The findings of this analysis indicate that the literature under the topic of SCPM is almost balanced between being theoretical and empirical. Related publications are almost divided equally; 50% for each. However, it is worth mentioning that in the last couple of years, tendency is higher towards empirical advancements where researchers focus on reporting the results of real practices in various application domains.

Nature of the Framework – Criterion:

One of the main challenges while analyzing the literature under a specific topic is how to address the various aspects of the works done. For instance, one can choose to classify the frameworks available in literature as either quantitative or qualitative. One might also classify the frameworks and approaches developed according to the dimensions based on which KPIs are identified and defined. However, the researchers decided to adopt a two-dimensional approach for describing the frameworks and methodologies developed for SCPM as follows:

Dimension One: Time

The literature associated with SCPM is huge. However in this review, the works done for this purpose are classified as static or dynamic to simplify the analysis as a first dimension. Static refers to the absence of a regular feedback component and thus the lack of continual improvement. Once systems are established, they are rooted and remain unchanged for a long time. While dynamic refers to the continuous monitoring of improvement to ensure organizations are actually measuring the most relevant business drivers, and hence enabling not only performance measurement and evaluation, but also performance management through setting strategies for improvement.

Dimension Two: Level

The second dimension of analysis relates to the level on which the developed frameworks measure performance. Some approaches are designed to measure the performance of specific individual organizations within the supply chain.

These approaches are referred to as entity level performance measurement ones. Other approaches suggest measuring performance of the whole supply chain including all sub entities. Such approaches are referred to as system level performance measurement methods.

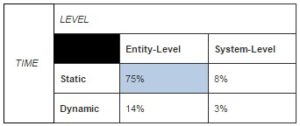

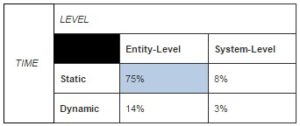

Results are reported in the matrix illustrated in table 3. The researchers summarize the analysis findings combining the two dimensions. However, the results of each dimension are also discussed separately. On the first dimension, 83% of the published researches coming mainly from the SCBS category discuss static frameworks versus only 17% discussing dynamic ones. Whereas results on the second dimension emphasize that the literature under SCPM topic is dominated by entity-level performance measurement approaches constituting 90% of the publications. The remaining 10% discussing system-level frameworks mainly focus on measuring the performance of green supply chains.

Table 3 – Classification of Literature on SCPM according to “Nature of the Framework” Criterion

Findings and Discussion:

The analysis of literature on SCPM explained earlier shows that the literature under this topic is almost balanced between theoretical and empirical efforts with a higher tendency in the recent years towards empirical developments. The results shown in table 3 indicate that the literature is primarily static – entity levelled. That is, the majority of the developed frameworks are static and designed to measure performance on the entity-level rather than the system-level. Even the dynamic approaches are mostly biased towards entity-level measurement as well. These findings emphasize the main limitations of currently existing SCPM systems illustrated earlier at the end of section 4; specifically points 4 and 5 (lack of holistic approach and being static).

In addition, throughout the analysis, it was also recognized that further developments in the area of SCPM require multi-disciplinary approach in order to address the different limitations. Hence, a number of key disciplines crucial to SCPM research are identified as follows: systems thinking, strategic planning and optimization.

Suggested Research Directions

Future contributions to the area of SCPM are possible and essential. They may come specifically from further research on the following as already initiated by Agami et al. (2011):

- Dynamic, system-level framework development efforts on both: theoretical and empirical fronts.

- Further elaboration on performance measurement to assess the degree of strategic fit.

- Developing performance measurement systems in the form of new maturity models supported by SCOR to enable benchmarking.

- Integrated methodology that addresses the holistic performance of complex supply chains using balanced appropriate KPIs.

- Shifting focus from performance measurement to its management and continuous improvement

Summary and Conclusion

This study reveals that the area of SCPM is growing in importance and scope. Both researchers and practitioners have been increasingly focusing on how to design and implement performance measurement systems for supply chains to cope with the continuous changes in their nature, context and requirements.

Throughout the different sections of this paper, the importance of performance measurement systems was initially explained and the evolution of SCPM systems over time was discussed. Then the literature in terms of common frameworks and approaches used for SCPM was reviewed and classified into nine distinct types according to their criteria of measurement. Finally, the criteria and findings of further literature analysis were explained.

It shows that most of the already existing SCPM systems are inflexible and lack continual improvement. Immaturity of the frameworks and models developed for this purpose is evident in this survey. And hence, SCPM is still a flourishing research area since a gap still exists between the research and potential application of current systems. Further research development efforts, as discussed in the last section of this paper, and future advancements are still needed.

(adsbygoogle = window.adsbygoogle || []).push({});

References

Abu-Suleiman, A., Boardman, B. & Priest, J. W. (2004). “A Framework for an Integrated Supply Chain Performance Management System,” Industrial Engineering Research Conference, Houston, TX.

Publisher – Google Scholar

Agami, N., Saleh, M. & Rasmy, M. (2011). ‘A Hybrid Dynamic Framework for Supply Chain Performance Improvement,’ IEEE Systems Journal, (in press).

Agarwal, A. & Shankar, R. (2005). “Modeling Supply Chain Performance Variables,” Asian Academy of Management Journal, 10(2), 47-68.

Publisher – Google Scholar

Ainapour, B., Singh, R. & Vittal, P. R. (2011). “TOC Approach for Supply Chain Performance Enhancement,” International Journal of Business Research and Management, 2(4), 163-178.

Publisher – Google Scholar

Akyuz, G. A. & Erkan, T. E. (2010). “Supply Chain Performance Measurement: A Literature Review,” International Journal of Production Research, 48(17), 5137-5155.

Publisher – Google Scholar

Basu, R. (2001). “New Criteria of Performance Management: A Transition from Enterprise to Collaborative Supply Chain,” Measuring Business Excellence Journal, 5(4), 7-12.

Publisher – Google Scholar

Beamon, B. M. (1999). ”Measuring Supply Chain Performance,” International Journal of Operations and Production Management, 19(3), 275-292.

Publisher – Google Scholar – British Library Direct

Beamon, B. M. & Ware, T. M. (1998). “A Process Quality Model for the Analysis, Improvement and Control of Supply Chain Systems,” Journal of Logistics Information Management, 11(2), 105–113.

Publisher – Google Scholar – British Library Direct

Berrah, L. & Chivlle, V. (2007). ‘Towards an Aggregation Performance Measurement System Model in a Supply Chain Context,’ Journal of Computers and Industrial Engineering, 58, 709-719.

Bhagwat, R. & Sharma, M. K. (2007). “Performance Measurement of Supply Chain Management: A Balanced Scorecard Approach,” Journal of Computers and Industrial Engineering, 53(1), 43-62.

Publisher – Google Scholar

Bititci, U., Suwignjo, P. & Carrie, A. (2000). “Quantitative Models for Performance Measurement System,” International Journal of Production Economics, 63(1-3), 231-241.

Publisher – Google Scholar

Bourne, M., Mills, J., Wilcox, M., Neely, A. & Platts, K. (2000). “Designing, Implementing and Updating Performance Measurement Systems,” International Journal of Operations and Productions Management, 20(7), 754-71.

Publisher – Google Scholar – British Library Direct

Bourne, M., Neely, A., Platts, K. & Mills, J. (2002). “The Success and Failure of Performance Measurement Initiatives: Perceptions of Participating Managers,” International Journal of Operations and Productions Management, 22(11), 1288-310.

Publisher – Google Scholar – British Library Direct

Brewer, P. C. & Speh, T. W. (2000). “Using the Balanced Scorecard to Measure Supply Chain Performance,” International Journal of Business Logistics, 21(1), 75-93.

Publisher – Google Scholar – British Library Direct

Cai, J., Liu, X., Xiao, Z. & Liu, J. (2009). “Improving Supply Chain Performance Management: A Systematic Approach to Analyzing Iterative KPIs Accomplishment,” Journal of Decision Support Systems, 46(2), 512-521.

Publisher – Google Scholar

Chan, F. T. S. (2003). “Performance Measurement in a Supply Chain,” International Journal of Advanced Manufacturing Technology, 21, 534 – 48.

Publisher – Google Scholar – British Library Direct

Chan, F. T. S. & Qi, H. J. (2003). “An Innovative Performance Measurement Method for Supply Chain Management,” Supply Chain Management: An International Journal, 8(3-4), 209 – 223.

Publisher – Google Scholar – British Library Direct

Charan, P., Shankar, R. & Baisya, R. (2007). ‘Selection of Supply Chain Performance Measurement System Using AHP Approach,’ POMS 18th Ann.

Google Scholar

Chen, I. J. & Paulraj, A. (2004). “Understanding Supply Chain Management: Critical Research and a Theoretical Framework,” International Journal of Production Research. 42(1), 131-63.

Publisher – Google Scholar – British Library Direct

Chen, Y., Liang, L. & Yang, F. (2006). “A DEA Game Model Approach to Supply Chain Efficiency,” Annals of Operations Research, 145(1), 5-13.

Publisher – Google Scholar – British Library Direct

Christopher, M. (2005). Logistics and Supply Chain Management: Creating Value-Adding Networks, FT Prentice Hall, London.

Publisher – Google Scholar

Cirtita, H. & Glaser-Segura, D. A. (2012). “Measuring Downstream Supply Chain Performance,” Journal of Manufacturing Technology Management, 23(3), 299-314.

Publisher – Google Scholar

Croom, S., Romano, P. & Giannakis, M. (2000). “Supply Chain Management: An Analytical Framework for Critical Literature Review,” European Journal of Purchasing and Supply Management, Vol. 6, 67 -83.

Publisher – Google Scholar – British Library Direct

Cuthbertson, R. & Piotrowicz, W. (2011). “Performance Measurement Systems in Supply Chains: A Framework for Contextual Analysis”, International Journal of Productivity and Performance Management, 60(6), 583-602.

Publisher – Google Scholar

Dasgupta, T. (2003). “Using the Six-Sigma Metric to Measure and Improve the Performance of a Supply Chain,” Total Quality Management Journal, 14(2), 355-366.

Publisher – Google Scholar – British Library Direct

De Toni, A. & Tonchia, S. (2001). “Performance Measurement Systems: Models, Characteristics and Measures,” International Journal of Operations and Production Management, 21(1-2), 46-70.

Publisher – Google Scholar – British Library Direct

Eccles, R. G. & Pyburn, P. J. (1992). ‘Creating a Comprehensive System to Measure Performance,’ Journal of Management Accounting, 41– 44.

Google Scholar

Estampe, D. & Lamouri, S. (2011). ‘A Framework for Analyzing Supply Chain Performance Evaluation Models,’ International Journal of Production Economics, (in press).

Fabbe-Costes, N. & Jahre, M. (2007). “Supply Chain Integration Gives Better Performance – The Emperor’s New Suit?,” International Journal of Physical Distribution and Logistics Management, 37(10), 835-55.

Publisher – Google Scholar – British Library Direct

Fynes, B., Voss, C. & de Búrca, S. (2005). “The Impact of Supply Chain Relationship Dynamics on Manufacturing Performance,” International Journal of Operations and Production Management. 25(1), 6 – 19.

Publisher – Google Scholar

Ghalayini, A. M. & Noble, J. S. (1996). “The Changing Basis of Performance Measurement,” International Journal of Operations and Production Management. 16(8), 63-80.

Publisher – Google Scholar – British Library Direct

Gunasekaran, A. & Kobu, B. (2007). “Performance Measures and Metrics in Logistics and Supply Chain Management: A Review of Recent Literature (1995–2004) for Research and Applications,” International Journal of Production Research, 45(12), 2819 – 2840.

Publisher – Google Scholar – British Library Direct

Gunasekaran, A., Patel, C. & McGaughey, R. E. (2004). “A Framework for Supply Chain Performance Measurement,” International Journal of Production Economics, 87(3), 333- 347.

Publisher – Google Scholar

Gunasekaran, A., Patel, C. & Tittiroglu, E. (2001). “Performance Measures And Metrics in a Supply Chain Environment,” International Journal of Operations and Production Management, 2(1-2), 71–87.

Publisher – Google Scholar – British Library Direct

Gunasekaran, A., Williams, H. J. & McGaughey, R. E. (2005). “Performance Measurement and Costing System in New Enterprise,” Journal of Technovation, 25(5), 523–33.

Publisher – Google Scholar

Hall, D. C. & Saygin, C. (2012). “Impact of Information Sharing on Supply Chain Performance,” The International Journal of Advanced Manufacturing Technology, 58(1-4), 397-409.

Publisher – Google Scholar

Harrison, A. & New, C. (2002). “The Role of Coherent Supply Chain Strategy and Performance Management in Achieving Competitive Advantage: An International Survey,” Journal of the Operational Research Society, 53(3), 263-271.

Publisher – Google Scholar – British Library Direct

Hausman, W. H. (2003). Supply Chain Performance Metrics, In: T. P. Harrison, H. Lee and J. J. Neale, ed. The Practice of Supply Chain Management: Where Theory and Application Converge, New York, Springer Science and Business, 61-7.

Publisher – Google Scholar – British Library Direct

Holmberg, S. (2000). “A Systems Perspective in Supply Chain Measurement,” International Journal of Physical Distribution and Logistics Management, 30(10), 847-68.

Publisher – Google Scholar – British Library Direct

Huang, S. H., Sheoran, S. K. & Wang, G. (2004). “A Review and Analysis of Supply Chain Operations Reference (SCOR) Model,” Supply Chain Management: An International Journal. 9(1), 23 – 29.

Publisher – Google Scholar – British Library Direct

Kaplan, R. S. & Bruns, W. (1987). ‘Accounting and Management: A Field Study Perspective,’ Harvard Business School Press.

Google Scholar

Kaplan, R. S. & Norton, D. P. (1992). “The Balanced Scorecard – Measures that Drive Performance,” Harvard Business Review, 70(January-February), 71-9.

Publisher – Google Scholar

Kaplan, R. S. & Norton, D. P. (2006). Alignment: Using the Balanced Scorecard to Create Corporate Synergies, Boston, MA: Harvard Business School Press.

Publisher – Google Scholar

Keebler, J. S. (2001). ‘Measuring Performance in the Supply Chain,’ Journal of Supply Chain Management, SAGE Publications, California.

Google Scholar

Kennerley, M. & Neely, A. (2002). “A Framework of the Factors Affecting the Evolution of Performance Measurement Systems,” International Journal of Operations and Production Management, 22(11), 1222-1245.

Publisher – Google Scholar – British Library Direct

Kennerley, M. & Neely, A. (2003). “Measuring Performance in a Changing Business Environment,” International Journal of Operations and Production Management, 23(2), 213-29.

Publisher – Google Scholar – British Library Direct

Kim, S. W. (2006). “Effects of Supply Chain Management Practices, Integration and Competition Capability on Performance,” Supply Chain Management: An International Journal. 11(3), 241-8.

Publisher – Google Scholar – British Library Direct

Kleijnen, J. P. & Smits, M. T. (2003). “Performance Metrics in Supply Chain Management,” Journal of the Operational Research Society, 54(5), 507-14.

Publisher – Google Scholar – British Library Direct

Koh, S. C. L., Demirbag, M., Bayraktar, E., Tatoglu, E. & Zaim, S. (2007). “The Impact of Supply Chain Management Practices on Performance of SMEs,” Industrial Management and Data Systems Journal, 107(1), 103-124.

Publisher – Google Scholar – British Library Direct

Kurien, G. P. & Qureshi, M. N. (2011). “Study of Performance Measurement Practices in Supply Chain Management,” International Journal of Business Management and Social Sciences, 2(4), 19-34.

Publisher – Google Scholar

Lai, K., Ngai, E. W. T. & Cheng, T. C. E. (2002). “Measures for Evaluating Supply Chain Performance in Transport Logistics,” Journal of Transportation Research: Part E, 38(6), 439-456.

Publisher – Google Scholar

Lambert, D. M. & Pohlen, T. L. (2001). “Supply Chain Metrics,” International Journal of Logistics Management, 12(1), 1 – 19.

Publisher – Google Scholar – British Library Direct

Lapide, L. (2000). “What about Measuring Supply Chain Performance?,” AMR Research, ASCET – White Paper, 2(15), 287-297.

Publisher – Google Scholar

Lauras, M., Lamothe, J. & Pingaud, H. (2011). “A Business Process Oriented Method to Design Supply Chain Performance Measurement Systems,” International Journal of Business Performance Management, 12(4), 354-376.

Publisher – Google Scholar

Liang, L., Feng, F., Cook, W. D. & Zhu, J. (2006). “DEA Models for Supply Chain Efficiency Evaluation,” Annals of Operations Research, 145(1), 35-49.

Publisher – Google Scholar – British Library Direct

Li, S., Rao, S. S., Ragu-Nathan, T. S. & Tagu-Nathan, B. (2005). “Development and Validation of a Measurement Instrument for Studying Supply Chain Practices,” Journal of Operations Management, 23, 618-41.

Publisher – Google Scholar

Li, Z., Xu, X. & Kumar, A. (2007). “Supply Chain Performance Evaluation from Structural and Operational Levels,” IEEE Conference on Emerging Technology and Factory Automation, (ETFA), 1131-1140.

Publisher – Google Scholar

Lockamy III, A. & McCormack, K. (2004). “Linking SCOR Planning Practices to Supply Chain Performance: An Exploratory Study,” International Journal of Operations and Production Management, 24(11-12), 1192-1218.

Publisher – Google Scholar – British Library Direct

Lohman, C., Fortuin, L. & Wounters, M. (2004). “Designing a Performance Measurement System a Case Study,” European Journal of Operational Research, 156(2), 267-86.

Publisher – Google Scholar

Lummus, R. R., Duclos, L. K. & Vokurka, R. J. (2003). “Supply Chain Flexibility: Building a New Model,” Global Journal of Flexible Systems Management, 4(4), 1-13.

Publisher – Google Scholar

Lynch, R. & Cross, K. (1991). ‘Measure Up – The Essential Guide to Measuring Business Performance,’ Mandarin, London.

Marr, B. & Schiuma, G. (2003). “Business Performance Measurement ± Past, Present and Future,” Journal of Management Decision, 41(8). 680-687.

Publisher – Google Scholar – British Library Direct

Martinez, V. & Kennerley, M. (June: 19-22, 2005). ‘Impact of Performance Management Reviews: Evidence from an Energy Supplier,’ EUROMA Conference, Operational and Global Competitiveness, Budapest, Hungry.

Marwah, A. K., Thakar, G. & Gupta, R. C. (2012). “Implications of Performance Measurement Approaches on Supply Chain Performance,” National Conference on Emerging Challenges for Sustainable Business, 1731-1760.

Publisher – Google Scholar

Maskell, B. H. (1992). ‘Performance Measurement for World Class Manufacturing: A Model for American Companies,’ Productivity Press, Cambridge, MA.

Google Scholar

McCormack, K., Ladeira, M. B. & de Oliviera, M. P. V. (2008). “Supply Chain Maturity and Performance in Brazil,” Supply Chain Management: An International Journal, 13(4), 272-282.

Publisher – Google Scholar

Medori, D. & Steeple, D. (2000). “A Framework for Auditing and Enhancing Performance Measurement Systems,” International Journal of Operations and Production Management, 20(10), 1119-1145.

Publisher – Google Scholar – British Library Direct

Melynk, S. A., Stewart, D. M. & Swink, M. (2004). “Metrics and Performance Measures in Operations Management: Dealing with the Metrics Maze,” Journal of Operations Management, 22, 209- 17.

Publisher – Google Scholar

Najmi, M., Rigasm J. & Fan, I.- S. (2005). “A Framework to Review Performance Measurement Systems,” Business Process Management Journal, 11(2), 109-122.

Publisher – Google Scholar

Neely, A. (1998). Measuring Business Performance, Economist Books, London.

Publisher – Google Scholar

Neely, A. (2005). “The Evolution of Performance Measurement Research: Development in the Last Decade and a Research Agenda for the Next,” International Journal of Operations and Production Management, 25(12), 1264-1277.

Publisher – Google Scholar – British Library Direct

Neely, A., Adams, C. & Crowe, P. (2001). “The Performance Prism in Practice,” Journal of Measuring Business Excellence, 5(2), 6 -13.

Publisher – Google Scholar – British Library Direct

Neely, A., Gregory, M. & Platts, K. (1995). “Performance Measurement Systems Design: A Literature Review and Research Agenda,” International Journal of Operations and Productions Management, 15(4), 80-116.

Publisher – Google Scholar – British Library Direct

Otto, A. & Kotzab, H. (2003). “Does Supply Chain Management Really Pay? Six Perspectives to Measure the Performance of Managing a Supply Chain,” European Journal of Operational Research, 144(2), 306-320.

Publisher – Google Scholar

Öztaysi, B. & Uçal, İ. (2009). “Comparing MADM Techniques for Use in Performance Measurement,” Proceedings of the International Symposium on the AHP.

Publisher – Google Scholar

Parker, C. (2000). “Performance Measurement,” Work Study, 49(2), 63-66.

Publisher – Google Scholar – British Library Direct

Petroni, A. & Panciroli, B. (2002). “Innovation as a Determinant of Suppliers’ Roles and Performances: An Empirical Study in the Food Machinery Industry,” European Journal of Purchasing and Supply Management, 8, 135-149.

Publisher – Google Scholar

Ramaa, A., Rangaswamy, T. & Subramanya, K. (2009). “A Review of Literature on Performance Measurement of Supply Chain Network,” 2nd International Conference on Emerging Trends in Engineering and Technology, 802-807.

Publisher – Google Scholar

Ren, C., Chan, Y. & Liu, Y. (2004). “Active Performance Management in Supply Chains,” IEEE International Conference on Systems, Man and Cybernetics.

Publisher – Google Scholar

Ren, T. (2008). “Application of Supply Chain Performance Measurement Based on SCOR Model,” This paper appears in: 4th International Conference on Wireless Communications, Networking and Mobile Computing.

Publisher – Google Scholar

Saad, M. & Patel, B. (2006). “An Investigation of Supply Chain Performance Measurement in the Indian Automotive Sector,” Benchmarking: An International Journal, 13(1-2), 36-53.

Publisher – Google Scholar – British Library Direct

Sahay, B. S., Gupta, J. N. D. & Mohan, R. (2006). “Managing Supply Chains for Competitiveness: The Indian Scenario,” Supply Chain Management: An International Journal, 11(1), 15- 24.

Publisher – Google Scholar – British Library Direct

Sarode, A., Sunnapwar, V. & Khodke, P. (2009). ‘A Literature Review for Identification of Performance Measures for Establishing a Framework for Performance Measurement in Supply Chains,’ International Journal of Applied Management and Technology, 6(3), 241-273.

Sharma, M. K. & Bhagwat, R. (2007). “An Integrated BSC-AHP Approach for Supply Chain Management Evaluation,” Journal of Measuring Business Excellence. 11(3), 57-68.

Publisher – Google Scholar – British Library Direct

Shepherd, C. & Günter, H. (2006). “Measuring Supply Chain Performance: Current Research and Future Directions,” International Journal of Production and Performance Management. 55(3-4), 242-258.

Publisher – Google Scholar – British Library Direct

Simchi-Levi, D., Kaminsky, P. & Simchi-Levi, E. (2002). ‘Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies,’ 2nd – New York: McGraw-Hill Higher Education.

Sobrino, D., Caganova, D. & Cambal, M. (2011). ‘Supply Chain Performance Measurement: Proposal of an Integral Indicator with a Multiple Criteria Approach For Supporting Decision Making,’ World Academy of Science, Engineering and Technology, 59, 148-154.

Stephens, S. (2001). “Supply Chain Operations Reference Model Version 5.0: A New Tool to Improve Supply Chain Efficiency and Achieve Best Practice,” Information Systems Frontiers, 3(4), 471-476.

Publisher – Google Scholar – British Library Direct

Stern, J. M., Stewart, G. B. & Chew, D. H. (1995). “The EVA® Financial Management System,” Journal of Applied Corporate Finance, 8(2), 32-46.

Publisher – Google Scholar – British Library Direct

Stewart, G. (1995). “Supply Chain Performance Benchmarking Study Reveals Keys to Supply Chain Excellence,” Journal of Logistics Information Management, 8(2), 38 – 44.

Publisher – Google Scholar – British Library Direct

Supply Chain Council. (2008). “SCOR Overview: Version 9.0.,” www.supply-chain.org, Supply-Chain Operations Reference-model.

Publisher

Talluri, S. & Sarkis, J. (2002). “A Model for Performance Monitoring of Suppliers,” International Journal of Production Research, 40(16), 4257-69.

Publisher – Google Scholar – British Library Direct

Tangen, S. (2004). “Performance Measurement: From Philosophy to Practice,” International Journal of Production and Performance Management, 53(8), 726-737.

Publisher – Google Scholar – British Library Direct

Tan, W. Z., Ting, Y. T. & Liu, Y. (2011). “Business Excellence Measurement of Supply Chains Based on Collaboration Degree and Service Level,” Advanced Materials Research, 339, 349-352.

Publisher – Google Scholar

Tian, C., Chai, Y., Liu, Y. & Ren, S. (2003). “Performance Management in Supply Chain,” This paper appears in: IEEE International Conference on Systems, Man and Cybernetics, 5, 4934- 4939.

Publisher – Google Scholar – British Library Direct

Tracey, M. & Tan, C. L. (2001). “Empirical Analysis of Supplier Selection and Involvement, Customer Satisfaction, and Firm Performance,” Supply Chain Management: An International Journal. 6(4), 174 – 188.

Publisher – Google Scholar – British Library Direct

Van Hoek, R. I. (1998). “Measuring the Unmeasurable – Measuring and Improving Performance in the Supply Chain,” Journal of Supply Chain Management, 3(4), 187-192.

Publisher – Google Scholar

Van Landeghem, R. & Persoons, K. (2001). “Benchmarking of Logistical Operations Based on a Causal Model,” International Journal of Operations and Production Management, 21(1-2), 254 – 267.

Publisher – Google Scholar – British Library Direct

Venkata, R. (2007). ‘Decision Making in the Manufacturing Environment,’ Chapter 3: Introduction to Multi Attribute Decision-making (MADM) Methods.

Google Scholar

Vereecke, A. & Muylle, S. (2006). “Performance Improvement through Supply Chain Collaboration in Europe,” International Journal of Operations and Production Management, 26(11), 1176 -1198.

Publisher – Google Scholar – British Library Direct

Wong, W. P. & Wong, K. Y. (2007). “Supply Chain Performance Measurement System Using DEA Modeling,” Journal of Industrial Management and Data Systems Information, 107(3). 361-381.

Publisher – Google Scholar – British Library Direct

Zhaofang, M., Xiaomei, L. & Fu, J. (2006). “A New Approach of Supply Network Performance Measurement Based on Supporting Level and Operational Level,” This paper appears in: Technology and Innovation Conference, 1537-1545.

Publisher – Google Scholar