Introduction

Today’s market and competitive pressures require companies to develop and maintain a high level of coherence between their strategy, action programmes, practices and performance. Rapidly changing competitive environments also put new demands on organizations. In order to meet these demands or stay ahead of competition, companies need to drive growth in the face of growing competition. They are finding that the key to keeping and acquiring customers is Operational Excellence.

Hayes and Wheelwright (1985) cited in Flynn et al. (1999) used the term “world class manufacturer” to describe organizations which achieved a global competitive advantage through the use of their manufacturing capabilities and competencies as a strategic weapon. For example, Toyota has turned operational excellence into a strategic weapon. This operational excellence is based in part on tools and quality improvement methods made famous by Toyota in the manufacturing world, such as just-in-time, kaizen, one-piece-flow, jidoka, and heijunka (that make up the Toyota Production System).

When review the development in the world business market such as the issues of globalization, fierce competition and technology advancements, Mokhtar and Yusoff (2009) suggest that manufacturing organisations in Malaysia need to have an ability to adjust and change to survive the challenging business environment. Organizations need to have a new set of capabilities to ensure their survival and growth in the market. Managers in a firm need to build its own internal competencies to deal with organization issues, change, and strategizing.

Operational excellence is not just a matter of cost reduction and quality improvement, but also being smart about how to handle people and resources. It requires solid change management capability and strong leadership to become operational excellence. Operational excellence is also very much dependent on employees’ empowerment, ownership and a culture of continuous improvement. Its adoption and introduction usually confronts a company with the need to change the way its employees think and act. Providing leadership for operational excellence comes down to balancing and combining control and individual autonomy and responsibility, and requires a very high level of employee commitment (Van Assen, 2011).

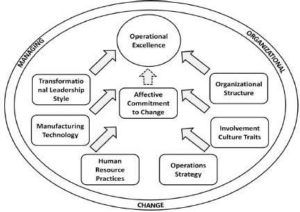

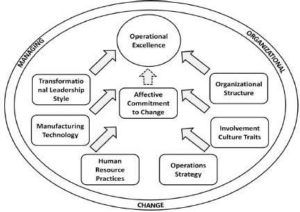

This paper adds to the slowly building body of knowledge on the managing organizational change (MOC). The approaches take to incorporate leadership style, manufacturing technology, human resource, organizational structure, organizational culture and operations strategy under the MOC. While adopting managing change is quite challenging as there are still many gaps in the understanding of each element. Therefore, the paper aims to quantify how well the electrical and electronics (E&E) companies in Malaysia fare with MOC and defining MOC as the practices used by, and having significant effect on the Operational Excellence (OPX) of companies. Furthermore, the authors will analyse the effect of affective commitment to change (CTC) in the relationship between MOC and OPX.

Problem Statement

In the past studies, operational performance measured quality, flexibility, speed and cost (Voss, 1995a; Yusuff, 2004; Laugen, et al., 2005; Kuruppuarachchi & Perera, 2010) which have focused mostly on economic measures of corporate performance. Studies in the area of social performance are still lacking (Muogboh & Salami, 2009). Therefore, the conceptual paper highlights how to overcome the perceived performance gap of implementing managing organizational change (MOC) in sustaining business excellence. The discussions on the literature review suggest to include both economic and non-economic measures (Elkington, 1997; Hubbard, 2009) that have an important impact on an organization’s long-term sustainability (Elkington, et al., 1999).

Operational management and performance have been an issue in both academia and industry for over three decades. The literature on operational excellence is growing, but Malaysian manufacturing industry is often lacking in these discussions. This study also attempts to understand further of Malaysia electrical and electronics firms managing change pertaining to operational excellence. In fact, the electrical & electronics (E&E) industry is the leading sector in Malaysia’s manufacturing sector, contributing significantly to the country’s manufacturing output (26.94 per cent), exports (48.7 per cent) and employment (32.5 per cent) (MIDA, 2012).

While change management depends on leadership to be enacted, specifically, the leadership style that is primarily concern with the capabilities required enacts change successfully (Eisenbach, et al., 1999, Burke & Church, 1993; Idris & Ali, 2008). Most of the research on the leadership paradigms has focussed on its relationship to followers (Bass & Avolio, 1994; Burns, 1978; Shin & Zhou, 2003); the success of TQM programs (Waldman, 1993; Choi and Behling, 1997); organizational outcomes such team performance (Sauer, 2011; Mannheim & Halamish, 2008); and financial performance (Idris & Ali, 2008). However, there were limited literatures done on leadership styles and its impact on operational excellence in manufacturing industry, especially in the Malaysian setting (Lo, et al., 2009).

Manufacturing technology has come from many sources. For example, flexible manufacturing system (FMS) (Roth et al, 1991), enterprise resource planning (ERP) (Mabert & Venkataramanan, 2000) office automation (OA) (Beaumont et al. 2002), computer, all of which are focused on doing things better, faster, more efficiency, and more cheaply. But the field is rather scattered with many articles focusing on one or a limited set of new technologies, while the reasons why these technologies are considered best are often not accounted for. Moreover, why these technologies, not others, the authors regard the set as comprehensive remains unclear. Therefore, having realized that there is lack of integrated manufacturing technologies on this area, it has driven the authors to make comparison of the manufacturing technology deployment among firms.

Kalyani and Sahoo (2011) argue Human Resource (HR) is an intellectual asset, the sum total of the knowledge, skills and competencies that an organization processes and channelizes for sustained organizational excellence. Court (2011) suggests the future role of the HR function should focus on helping their organization to learn how to build a capability to change. To bridge the flaws and gaps in the recent literatures, authors attempts to examine how firms sustaining operational excellence are influenced by firm managing change in human resource practices such as recruitment and selection, training and development, compensation systems and performance appraisal (Ferguson & Reio Jr., 2009; Gurbuz & Mert, 2011; Kalyani & Sahoo, 2011; Stavrou-Costea, 2004; Dimba, 2010; Khan, 2010) in broad range of manufacturing firms.

Ashkenas et al. (1995) argue almost every organization experimented with some kind of structural change process. In order to match up with environmental changes, organizations must adopt optimum innovative organization design (structure) leads to superior performance. Recent research, Mansoor et al. (2012) suggest that organic structure works well under dynamic or change environmental condition, especially in private sector in terms of performance as well as effectiveness where employees are involved in decision making. However, little empirical research has been carried out into the role of managing change in organizational structure to predict organizational performance or operational excellence. In author opinion, this is a serious deficiency because organizational structure is the basic mechanism available to the organization and their members for making decision and improves performance.

Changing to a culture of continuous improvement usually requires a paradigm shift. This change requires taking risks, opening up the firm culture and a great capacity to learn (Markovic, 2008). You et al. (2010) suggest that a link between corporate culture traits such as consistency, mission, involvement, and adaptability and business performance exits. Thus, this study helps to test a link between corporate culture traits and operational excellence in Malaysia, with its unique culture and concentred business environment. This paper helps fill this gap in the literature using the electrical and electronics industry.

Operations strategy has often been written as an entity within itself, aside of the strategy or business mainstream. The monitoring mechanisms include operations strategy construct consists of four dimensions (i.e. flexibility strategy, quality strategy, delivery strategy, and cost strategy) used by Skinner (1974) and Schniederjans and Cao (2009). In this study, a focus will be on change in operations strategy to predict operational excellence in quality, flexibility, time, cost (Brown, et al., 2010) and sustainability (Muogboh & Salami, 2009).

Change initiatives involve people. An employee commitment to change (CTC) might create as impact either positively or negatively (Herscovitch and Meyer, 2002; Peus, et al., 2009; Jaros, 2010) on an organization. Huy (2002) find that the most prevalent factor contributing to failed change projects is a lack of commitment by the people. Despite its presumed importance, and it commonly identified as an essential element for the effective implementation of organizational change, however, little empirical evidence exists to support this claim (Herscovitch & Meyer, 2002; Meyer, et al., 2007). Hence, the moderating effect of CTC to be examined in this study. Yet, previous study on MOC has not included the impact of CTC per se as a factor that is able to moderate the operational excellence.

Overall, literatures indicate that firm managing organizational change is vital in ensuring competitive advantage to the firms (Kanter, 1985; Kotter, 2007). In essence, effective approaches in organizational change will involve not only one element but also have to understand other relevant elements of entire organization. Moreover, managing organizational change (MOC) and these six elements have not being integrated in any research which develop new knowledge in the study of operational excellence. In addition, employees’ commitment to change is also important (Herscovitch & Meyer, 2002; Peus, et al., 2009; Jaros, 2010; Herold, et al., 2008) as it influences the change successful in the relationship between MOC and OPX. Integrating MOC maturity with associated CTC efforts in order to remain competitive, is absent in most Operational Excellence initiatives.

Literature Review

Operational Excellence

According to Hillman (1994), assessment of excellence is the process of evaluating an organization against a model for continuous improvement in order to highlight what has been achieved and what needs improving. European Foundation for Quality Management (EFQM guidelines, 1999) defines excellence as ‘‘outstanding practice in managing the organization and achieving results”.

In this study, results from application of operational excellence are focused operational performance and organizational sustainable performance. Operational performance reflects the performance of internal operations of a company in terms of quality improvements, flexibility improvement, delivery improvement, productivity improvement, cost and waste reduction. The organizational sustainable performance indicator measures in present study are environment performance and social performance, while the financial measures such as sales growth, profit growth, return on equity (ROE), return on assets (ROA) and gearing (Hubbard, 2009) will be ignored. In fact, many E&E manufacturing firms in Malaysia are owned by foreign investors and may listed in the their home country, thus the respondents may not be privy to the information and data related to financial performance. Although performance can be measured either as financial performance or as operational performance, operational priorities are more relevant than financial goals at the plant level (Venkatraman and Ramanujam, 1986; Brown, 2007).

Van Assen (2011) argues that operational excellence is not just a matter of cost reduction and quality improvement, but also being smart about how to handle people and resources. It requires solid change management capability and strong leadership to become operational excellence. Operational excellence is also very much dependent on employees’ empowerment, ownership and a culture of continuous improvement. Its adoption and introduction usually confronts a company with the need to change the way its employees think and act.

This paper discusses the performance indicators (i.e. quality, time, flexibility, cost and sustainability) may use to measure firm performance in achieving operational excellence. More specific, the dependent variable, operational excellence will be operationalized by quality, flexibility, speed, cost, social and environmental in present study. Moreover, managing people, technology, leadership, strategy, structure, culture and employees’ commitment to change are important variables affect the operational excellence.

Evolution of Excellence

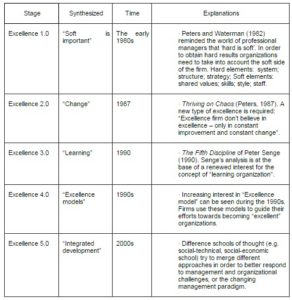

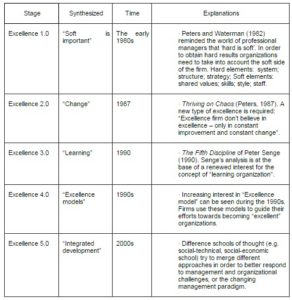

During the last 30 years, both definition and sustainability of excellence evaluations have undergone repeated changes. Hermal and Pujol (2003) have synthesized ‘excellence’ into five main stages and defining each excellence stage in details in literature. The synthetic conclusion of excellence is shown in Table 1.1.

Table 1.1: Synthetic Conclusion of Excellence

Source: Adapted from Hermal and Pujol (2003)

Hermal and Pujol (2003) further explain that the series of excellence stages proposed are only tentative and could certainly be disposed in many different ways. They just hope that the different points addressed are at the base of production debate.

Managing Organizational Change

Due to the fact that the future and success of every organization depends on how well manager handle change (Kalyani and Sahoo, 2011; Peus, et al., 2009), therefore, discussion on this report is assessing the relationship between managing organizational change (MOC) and operational excellence. MOC means planning and realizing changes that concern organization’s strategic success factors. These success factors might be the meaning of it, its policies, competencies and the capability of renewal. The firm critical success factors that influence organizational changes also identify through the empirical evidence.

Leadership Style

Leadership is the other key component of successful change. Leadership is the first criterion of the European Foundation for Quality Management (EFQM) Excellence Model, a model of organizational excellence which is used by more than 30,000 organizations across Europe (EFQM, 2010).

Leadership has been recognized as a major factor on organization success and this has been empirically validated throughout many fields. However, a leadership style in the context of managing organizational change and its impact on operational excellence in manufacturing industry has not been as widely research. While managing organizational change is depends on leadership to be enacted, particularly; the leadership style that is primarily concern with the capabilities required enacts change successfully (Eisenbach, et al., 1999; Burke & Church, 1993; Idris & Ali, 2008). Moreover, a transformational style of leadership is perceived can produce positive organizational change and create exceptional performance (Bass, 1985; Boehnke, et al., 2003; Burke & Church, 1993). In the present study, we are interested in examining the positive impact of transformational leadership style on operational excellence. Hence, the researchers offer the following statement of proposition:

P1: The inclination towards the transformational leadership style leads to an operational excellence.

Manufacturing Technology

Modern technology is playing a key role in the ability of manufacturing companies to compete as world-class enterprises. Therefore, new manufacturing technologies are needed to assist in compressing the production time to move products to the market more quickly and efficiently than competitors (Chuang, et. al, 2009). Indeed, acquiring and implementing new technologies are perceived as high-risk investments and determinants of competition.

Most of the literature review has found manufacturing technologies such as AMT, TQM, JIT, and ERP have shown to have significant on firm performance. Overall, the literature indicates that manufacturing technologies should be incorporate with a change measuring framework.

Therefore, it is agreed that the manufacturing technology management construct consist of selection, acquisition and exploitation, is based on three out of five technology management assessment indicators in the study of Kuruppuarachchi & Perera (2010). This justifies that even the organizations are capable of selection and acquisition of new technology, lack of technology exploitation or enhancement would lower down the performance dimensions, especially quality, cost, delivery, flexibility and sustainability. Thus, the following proposition captures the relationship between manufacturing technology and operational excellence.

P2: The use of the manufacturing technology leads to a favorable impact on the operational excellence.

Human Resource

Any change program would revolve around people, changing their mind set, behaviour and motivational level. HR has always been central to organizations, to-day it has taken on an even more central role in building a firm’s competitive advantage. Success increasingly depends on “people-embodied know-how”. Thus, includes the knowledge, skills, and abilities imbedded in an organization’s member (Kalyani & Sahoo, 2011). HR is an intellectual asset, the sum total of the knowledge, skills and competencies that an organization processes and channelizes for sustained organizational excellence. Excellence is surpassing on outstanding achievement, achievable by the use of HR strategies and practices as tool.

Very little attention has been paid to address the impact of managing human resource change on operational excellence. The universal use of HR practices such as recruitment and selection, training and development, performance appraisal, and compensation and benefits (Ferguson & Reio Jr., 2009; Gurbuz & Mert, 2011; Kalyani & Sahoo, 2011; Stavrou-Costea, 2004; Dimba, 2010; Khan, 2010) could be explored in present study to predict operational excellence. New knowledge generate from this study could inform theory building efforts in the HR field, particularly as it related to human resource-based view to meaningful organization outcomes and in due course excellence. Therefore, we suggest that human resource practices lead to positive impact to operational excellence.

P3: Effectiveness of human resource practices leads to positive impact on the operational excellence.

Organizational Structure

The major dimensions that characterize an organization’s structure are its degree of centralization of decision making, and the formalization of rules and procedures. In order to achieve higher performance, appropriate structure is needed which suits best in changing organization’s demand. The choice of an appropriate structure highly depends upon the condition in which an organization is operating (Mansoor, et al., 2012). For instant, stable and change environment cannot be treated equally.

Rather than using the dichotomy proposed by Burns and Stalker (1961), which considers the level of formalization and centralization, this research focuses on formalization and decentralization. It describes an organic structure as having formal rules and procedures that encourage creativity, autonomous work, learning, and decentralization of decision making to the greatest extent possible (Daft, 1995; Nahm, et al., 2003). Therefore, it will be interesting to explore this organic structure have significant relationship on operational excellence in Malaysia E&E industry. The proposition proposes as follows:

P4: The implementation of an organic structure will have a better impact on operational excellence.

Organizational Culture

Operational excellence is an enterprise culture that improves the way a corporation delivers products and services to its customers. Operational excellence calls for more than subject matter expertise and a talented internal team. It requires a deep commitment and a culture of change.

The current perspective embraces on managing change and focus on internal organization, therefore, the involvement trait (Internal Focus) is the best dimension to evaluate its effecting desired change within organization (Denison et al., 2003; You et al., 2010). This trait is measured by the three indices namely empowerment, team orientation and capability development. In addition, Denison (1990) found empirical support for the involvement view of culture, higher levels of employee participation were correlated with better organizational performance. Whilst organizational culture has been researched worldwide, little research has been done in Malaysia, with its unique culture and concentred business environment. This leads to the following proposition:

P5: Higher levels of individual involvement cultural trait leads to a positive impact on operational excellence.

Operations Strategy

Operations strategy literature has often been contextualised within manufacturing paradigms (Brown, et al., 2010). They summarized that firm’s operations were linked to specific modern manufacturing terms which included mass customization, flexible specialisation, lean production and lean supply, agile manufacturing, strategic manufacturing.

An analysing of the literature reveals there are gaps in the previous literature including the specific links between change capability and operations strategy; and the links between these two entities and performance measures at manufacturing. To surpass this shortcoming, a new focus will be on change capability in operations strategy to predict operational excellence in quality, flexibility, time, cost (Brown, et al., 2010) and sustainability (Muogboh & Salami, 2009). Additionally the change capability in operations strategy is based on Skinner’s (1969) initial framework.

‘Managing organizational change’ appears a simple enough term. However, no common ontological assumption underlies either the notion of ‘managing organizational’ or that of ‘organizational change’. Drawing lessons from the extensive literatures review, the authors establishes the link between managing organizational change and operational excellence. In this paper, we identify six critical organizational factors that will be incorporated under managing organizational change (MOC) to predict outcomes from operational excellence. Thus, we focus the six elements commonly associated with managing organizational change namely leadership, manufacturing technology, human resource, organizational structure, organizational culture, and operations strategy. In view of this, this research assumes that:

P6: Well defined of an operations strategy leads to an operational excellence.

Commitment to Change

There are a number of moderators that have impact on the perception of change; organizational commitment has been identified as a moderator (Vakola & Nikolaou, 2005). These moderators affect the individual’s commitment to cope with the change event. In addition to the main effects of the three components of commitment, Meyer and Allen (1991) also emphasized the importance of studying their moderating or interactive effects.

Although commitment researchers (e.g. Meyer & Allen, 1991; Herscovitch & Meyer, 2002) have identified three types of commitment: affective, normative, and continuance. This study will only focus on affective commitment has moderating effect for three reasons.

First, affective commitment best reflects alignment with, or positive attitude toward, a change effort, which is commonly referred to as “buy-in”. Employees who are affectively committed to an organization are more likely to exhibit constructive behaviors such as better work performance (Shum, et al., 2008). Second, among the three dimensions of commitment to change, affective commitment is the core component of employees’ commitment models (Herold, et al. 2008; Solinger et al., 2008). Solinger et al. (2008) further suggested that affective commitment is especially relevant when employees are expected to adjust to organizational change and to help organizations to achieve superb performance. Third, the present study of managing organizational change focus on widely recommended strategies for implementing change such as transformation, training, participation and empowerment are likely to impact on support for, and identification with, the change and thus influence by employees’ affective commitment to change (Herscovitch amd Meyer, 2002).

On this basis of argument, we expected to see greater effect of affective commitment on the relationship between MOC and OPX. Therefore, we assume that employees’ affective commitment moderates the relationship between MOC and OPX. From these reviews, the proposition reflecting the moderating influence of CTC on the relationship between MOC and OPX are derived as follows;

P7: Affective commitment to change has influence the relationship between the management of change and operational excellence.

Integration with Resource-based View (RBV) for Research Framework

The RBV is the dominant theory being used in the empirical literature on organization’s internal resources or capabilities and performance (Barney and Arikan, 2001; Ray, et al., 2004). The RBV deals with the competitive environment facing the organization but takes an ‘inside-out’ approach. Its starting point is the organization’s internal environment.

The primary objective emerges from the literature review for the future study to explore how firm manages its resources in relation to the operational excellence. The gaps in the literature review recommended that the holistic view and an integrative approach in internal environment, within the organization that involve change is need to be explored further. Therefore, RBV is appropriate to integrate the firm’s resources like strategy, leadership, technology, human resource, structure and culture to predict the outcomes, i.e. organizational excellence.

A research framework is used to outline possible course of action or to present a preferred approach to an idea or thought. By referring to the empirical review, the present study develops a conceptual framewotk that incorporate the important of MOC factors for OPX. The relationship among the various factors discussed in this literature is depicted in a framework as shown in Figure 1 below. Based on the literatured syntheses, the authors develops a linkage that the MOC factors and are likely to contribute positively to the OPX of the organization only in situations where the employees’ committed to change in the MOC efforts.

Figure 1: Conceptual Framework

Therefore, the propositions are developed based on the literature review, is to focus on research and provide direction and it is a vital component of a future study. The relationships are conjectured from the network of relationship illustrated by the propositions below:

P1: The inclination towards the transformational leadership style leads to an operational excellence.

P2: The use of the manufacturing technology leads to a favorable impact on the operational excellence.

P3: Effectiveness of human resource practices leads to positive impact on the operational excellence.

P4: The implementation of an organic structure will have a better impact on operational excellence.

P5: Higher levels of individual involvement cultural trait leads to a positive impact on operational excellence.

P6: Well defined of an operations strategy leads to an operational excellence.

P7: Affective commitment to change has influence the relationship between the management of change and operational excellence.

Review of the literature identifies the gaps in the methodology where it leans more towards a causal is vital for the future study. It is necessary to identify cause-and-effect relationship among variables when there is a connection established from the previous studies (Zikmund, 2003). The future study is also appropriate to consider the manager who involved in the manufacturing operations to give inputs on the subject matter, since as highlighted in the previous studies that they are the appropriate resource person for the OPX.

Discussion and Conclusion

The paper provides the conceptual understanding on the effect of managing organizational change and affective commitment to change on operational excellence. The literature review leads to the development of a conceptual framewotk that incorporate the influence of management of change to the oprational excellence. The paper organises the burgeoning management of change literature into six main elements: leadership style, manufacturing technology, human resource, organizational culture, organizational structure and operations strategy. The paper describes a linkage that the management of change factors and are likely to contribute positively to the operational excellence of the organization only in situations where the employees’ committed to change in the management of change efforts. This gaps in the literature also shows that there is a need for a study in the context of the Malaysian Electrical and Electronics (E&E) industry. The target of respondents who are suitable to answer the research questions concerns are the top managers and those closely linked to manufacturing operations including the General Manager, Operation Manager, Factory Manager, Production Manager, Engineering Manager, Manufacturing Manager, Planning Manager, Materials Manager, Lean Manager and Project Manager (involve in Change Management or Continuous Improvement programs).

The conceptual understanding highlighted in this paper is in three folds. First, managers of manufacturing may adopt change management to achieve operational excellence objectives of company. Second, the focus on five competitive priorities which are included quality, delivery, flexibility, cost (Voss, 1995a; Yusuff, 2004; Laugen, et al., 2005; Kuruppuarachchi & Perera, 2010) and sustainability (Elkington, et al., 1999; Muogboh & Salami, 2009), present actionable guidelines for managers. Managers may start formulation of manufacturing strategy even with regular demand of products. Third, adoption of change management practices will improve infrastructural decision areas of manufacturing strategy such as benchmarking, best practices, quality practices and HR policies. In contrast to most previous studies identified each of element separately, this paper demonstrates that the integration of organizational factors under managing organizational change would help in improving the operational excellence. From the theoretical perspective, it is discovered that the resource-based view provides significant insight into manufacturing operations and change management theories.

(adsbygoogle = window.adsbygoogle || []).push({});

References

Ashkenas, R., Ulrich, D., Jick, T. & Kerr, S. (1995). “The Boundaryless Organization Breaking the Chains of Organizational Structure,” San Francisco, Jossey-Bass.

Publisher

Barney, J. B. & Arikan, A. M. (2001). “The Resource-Based View: Origins and Implications,” In Handbook of Strategic Management, Hitt MA, Freeman RE, Harrison JS (eds), Blackwell: Oxford, U.K. Pp. 124-188.

Publisher – Google Scholar

Bass, B. M. (1985). “Leadership and Performance beyond Expectations,” New York: Free Press.

Publisher – Google Scholar

Bass, B. M. & Avolio, B. J. (1994). ‘Introduction: Improving Organizational Leadership,‘ Sage Publications, London.

Beaumont, N., Schroder, R. & Sohal, A. (2002). “Do Foreign-Owned Firms Manage Advanced Manufacturing Technology Better,” International Journal of Operations & Production Management 22 (7), 759-771.

Publisher – Google Scholar

Boehnke, K., Bontis, N., DiStefano, J. J. & DiStefano, A. C. (2003). “Transformational Leadership: An Examination of Cross-National Differences and Similarities,” Leadership & Organization Development Journal 24 (1). 5-15.

Publisher – Google Scholar

Brown, S., Squire, B. & Blackmon, K. (2007). “The Contribution of Manufacturing Strategy Involvement and Alignment to World-Class Manufacturing Performance,” International Journal of Operations & Production Management 27 (3), 282-302.

Publisher – Google Scholar

Brown, S., Squire, B. & Lewis, M. (2010). “The Impact of Inclusive and Fragmented Operations Strategy Processes on Operational Performance,” International Journal of Production Research 48 (3), 4179-4198.

Publisher – Google Scholar

Burke, W. W. & Church, A. H. (1993). “Managing Change, Leadership Style, and Intolerance to Ambiguity: A Survey of Organization Development Practitioners,” Human Resource Management 31 (4), 301-318.

Publisher – Google Scholar

Burns, J. M. (1978). ‘Leadership,’ New York: Harper and Row.

Google Scholar

Burns, T. & Stalker, G. M., (1961). “The Management of Innovation,” Tavistock, London.

Publisher – Google Scholar

Choi, T. Y. & Behling, O. C. (1997). “Top Managers and TQM Success: One More Look after All these Years,” Academy of Management Executives. 11 (1), 37-47.

Publisher – Google Scholar

Chuang, M., Yang, Y. S. & Lin, C. T. (2009). “Production Technology Selection: Deploying Market Requirements, Competitive and Operational Strategies, and Manufacturing Attributes,” International Journal of Computer Integrated Manufacturing, 22 (4), 345-355.

Publisher – Google Scholar

Court, T. (2011). “How the HR Function Can Build the Capacity to Change,” Development and Learning in Organizations, 25 (1), 16-18.

Publisher

Daft, R. L. (1995). Organization Theory and Design, 5th ed. West Publishing Company, St. Paul, MN.

Publisher

Denison, D. R. (1990). Corporate Culture and Organizational Effectiveness, New York, John Wiley & Sons.

Publisher – Google Scholar

Denison, D. R., Haaland, S. & Goelzer, P. (2003). “Corporate Culture and Organizational Effectiveness: Is There a Similar Pattern around the World?,” Advances in Global Leadership, 3 (2), 205-227.

Publisher – Google Scholar

Dimba, A. D. (2010). “Strategic Human Resource Management Practices: Effect on Performance,” African Journal of Economic and Management Studies, 1 (2), 128-137.

Publisher – Google Scholar

EFQM (European Foundation for Quality Management) (1999). ‘The Excellence Model,’ EFQM, Brussels.

EFQM (European Foundation for Quality Management) (2010). ‘The Excellence Model,’ EFQM, Brussels.

Eisenbach, R., Watson, K. & Pillai, R. (1999). “Transformational Leadership in the Context of Organizational Change,”Journal of Organizational Change Management, 12 (2), 80-88.

Publisher – Google Scholar

Elkington, J. (1997). ‘Cannibals with Forks: The Triple Bottom Line of 21st Century Business,’ Capstone, New Society. Google Scholar

Elkington, J. et al. (1999). ‘Triple Bottom Line Revolution: Reporting for the Third Millennium,’ Australian CPA, 69 (11), 75-77.

Google Scholar

Ferguson, K. L. & Reio Jr. T. G. (2009). “Human Resource Management Systems and Firm Performance,” Journal of Management Development, 29 (5), 471-494.

Publisher – Google Scholar

Flynn, B. B., Schroeder, R. G. & Flynn, E. J. (1999). “World Class Manufacturing: An Investigation of Hayes and Wheelwright’s Foundation,” Journal of Operations Management. 17 (3), 249-269.

Publisher – Google Scholar

FMM Directory of Malaysian Industries (2012). Federation of Malaysian Manufacturers (FMM).

Gurbuz, S. & Mert, I. S. (2011). “Impact of the Strategic Human Resource Management on Organizational Performance: Evidence from Turkey,” The International Journal of Human resource Management, 22 (8), 1803-1822.

Publisher – Google Scholar

Hermal, P. & Pujol, F. R. (2003). “An Evolution of Excellence Some Main Trends,” The TQM Magazine, 15 (4), 230-243.

Publisher – Google Scholar

Herold, D. M., Fedor, D. B., Caldwell, S. & Liu, Y. (2008). “The Effects of Transformational and Change Leadership on Employees’ Commitment to a Change: A Multilevel Study,” Journal of Applied Psychology. 93 (2), 346-357.

Publisher – Google Scholar

Herscovitch, L. & Meyer, J. P. (2002). “Commitment to Organization Change: Extension of a Three-Component Model,” Journal of Applied Psychology. (3), 474-487.

Publisher – Google Scholar

Hillman, G. P. (1994). “Making Self Assessment Successful,” The TQM Magazine, 6 (3), 29-31.

Publisher – Google Scholar

Hubbard, G. (2009). “Measuring Organizational Performance: Beyond the Triple Bottom Line,” Business Strategy and the Environment, 19, 177-191.

Publisher – Google Scholar

Huy, Q. N. (2002). “Emotional Balancing of Organizational Continuity and Radical Change: The Contribution of Middle Managers,” Administrative Science Quarterly, 47 (1), 31–69.

Publisher – Google Scholar

Idris, F. & Ali, K. A. M. (2008). “The Impacts of Leadership Style and Best Practices on Company Performances: Empirical Evidence from Business Firms in Malaysia,” Total Quality Management. 19, Nos. 1-2, 163-171.

Publisher – Google Scholar

Jaros, S. (2010). “Commitment to Organizational Change: A Critical Review,” Journal of Change Management. 10 (1), 79-108.

Publisher – Google Scholar

Kalyani, M. & Sahoo, M. P. (2011). “Human Resource Strategy: A Tool of Managing Change for Organizational Excellence,” International Journal of Business and Management. 6 (8), 280-286.

Publisher – Google Scholar

Kanter, R. (1985). “The Change Masters: Corporate Entrepreneurs at Work,” Unwin Paperbacks,’ London. 84-87, 304-306.

Publisher

Khan, M. A. (2010). ‘Effects of Human Resource Management Practices on Organizational Performance – An Empirical Study of Oil and Gas Industry in Pakistan,’ European Journal of Economics, Finance and Administrative Sciences, (24), 157-175.

Google Scholar

Kotter, J. P. (2007). ‘Leading Change Why Transformation Efforts Fail,’ Harvard Business Review, 85 (1), 96-103.

Google Scholar

Laugen, B. T., Acur, N., Boer, H. & Frick. J. (2005). “Best Manufacturing Practices: What Do the Best Performing Companies Do?,” International Journal of Operation & Production Management, 25, 131-150.

Publisher – Google Scholar

Lo, M. C., Ramayah, T. & Min, H. W. (2009). “Leadership Styles and Organizational Commitment: A Test on Malaysia Manufacturing Industry,” African Journal of Marketing Management. 6, 133-139.

Publisher – Google Scholar

Mabert, V., A. S. & Venkataramanan, M. (2000). ‘Enterprise Resource Planning Survey of U.S. Firms,’ Production and Inventory Management Journal, 41 (2), 52–58.

Markovic, M. R. (2008). “Managing the Organizational Change and Culture in the Age of Globalization,” Journal of Business Economics and Management, 9 (1), 3-11.

Publisher – Google Scholar

Mansoor, N., Aslam, H. D., Barbu, C. M., Capusneanu, S. & Lodhi, M. A. (2012). ‘Organizational Structure as Determinant of Organizational Performance: Uncovering Essential Facts of Organic and Mechanistic Structure,’ American Journal of Scientific Research, (55), 48-55.

Meyer, J. P. & Allen, N. J. (1991). “A Three-Component Conceptualization of Organizational Commitment,” Human Resource Management Review, 1 (1), 61-89.

Publisher – Google Scholar

Meyer, J. P., Srinivas, E. S., Lai, J. B. & Topolnytsky, L. (2007). “Employee Commitment and Support for an Organization Change: Test of the Three Component Model in Two Cultures,” Journal of Occupational and Organizational Psychology, 80, 185-211.

Publisher – Google Scholar

MIDA (Malaysian Investment Development Authority) (2012). [Online] [Retrieved November 21, 2012]. Available: http://1web.mida.gov.my/env3/index.php?page=ee

Mokhtar, S, S, M. & Yusoff, R. Z. (2009). “Exploring the Relationship of Key Strategic Orientation towards Sustainable Organizational Performance,” International Journal of Business and Management Science, 2 (1), 79-87.

Publisher

Muogboh, O. S. & Salami, A. (2009). “A New Perspective on the Manufacturing Strategy: Performance Relationship,” International Journal of Business Research, 9 (3), 114-126.

Publisher

Nahm, A. Y., Vonderembse, M. A. & Koufteros, X. A. (2003). “The Impact of Organizational Structure on Time-based Manufacturing and Plant Performance,” Journal of Operations Management. 21, 281-306.

Publisher – Google Scholar

Perera, H. S. C. & Kuruppuarachchi, D. (2010). “Impact of TQM and Technology Management on Operations Performance,” Journal of Operations Management, 23-47.

Publisher – Google Scholar

Peus, C., Frey, D., Gerkhardt, M., Fischer, P. & Traut-Mattausch, E. (2009). “Leading and Managing Organizational Change Initiatives,” Management Review, 20 (2), 158-175.

Publisher – Google Scholar

Ray, G., Barney, J. B. & Muhanna, W. A. (2004). “Capabilities, Business Processes and Competitive Advantage: Choosing the Dependent Variable in Empirical Test of Resource-Based View,” Strategic Management Journal, 25, 23-37.

Publisher – Google Scholar

Roth, A.V., Gaimon, C. & Krajewski, L. (1991). “Optimal Acquisition of FMS Technology Subject to Technological Progress,” Decision Sciences. 22, 308–334.

Publisher – Google Scholar

Sauer, S. J. (2011). “Taking the Reins: The Effects of New Leader Status and Leadership Style on Team Performance,” Journal of Applied Psychology, 96 (3), 574-587.

Publisher – Google Scholar

Schniederjans, M. & Cao, Q. (2009). “Alignment of Operations Strategy, Information Strategic Orientation, and Performance: An Empirical Study,” International Journal of Production Research, 47 (10), 2535-2563.

Publisher – Google Scholar

Shin, S. J. & Zhou, J. (2003). “Transformational Leadership, Conservation, and Creativity: Evidence from Korea,” Academy of Management Journal, 46 (6), 703-714.

Publisher – Google Scholar

Shum, P., Bove, L. & Auh, S. (2008). “Employees’ Affective Commitment to change: The Key to Successful CRM Implementation,” European Journal of Marketing. 42 (11), 1346-1371.

Publisher – Google Scholar

Skinner, W. (1969). “Manufacturing: the Missing Link in Corporate Strategy,” Harvard Business Review. 47, 136–145.

Publisher

Skinner, W. (1974). The Focused Factory, Harvard Business Review. 3, 113-119.

Publisher – Google Scholar

Solinger, O. N., van Olffen, W. & Roe, R. A. (2008). “Beyond the Three Component Model of Organizational Commitment,” Journal of Applied Psychology. 93 (1), 70–83.

Publisher – Google Scholar

Stavrou-Costea, E. (2004). “The Challenges of Human Resource Management towards Organizational Effectiveness: A Comparative Study in Southern EU,” Journal of European Industrial Training. 29 (2), 112-134.

Publisher – Google Scholar

Vakola, M. & Nikolaou, I. (2005). “Attitudes towards Organizational Change: What is the Role of Employees’ Stress and Commitment?,” Employee Relations, 27 (2), 160-174.

Publisher – Google Scholar

Van Assen, M. F. (2011). “Operational Excellence for Services,” Center of Operational Excellence,”[Online]. [Retrieved February 29, 2012]. Available at: http://www.vanassen.info/wp-content/uploads/Position-paper-Operational-Excellence-for-Services.pdf

Publisher – Google Scholar

Venkatraman, N. & Ramanujam, V. (1986). “Measurement of Business Performance in Strategy Research: A Comparison of Approaches,” Academy of Management Review. 11, 801-814.

Publisher – Google Scholar

Voss, C. A. (1995a). “Alternative Paradigms for Manufacturing Strategy,” International Journal of Operations & Production Management, 15 (4). 5-16.

Publisher – Google Scholar

Waldman, D. A. (1993). “Designing Performance Measurement Systems for Total Quality Implementation,” Journal of Organizational Change Management. 7 (2), 31–44.

Publisher – Google Scholar

You, C. L. K., Coulthard, M. & Petkovic-Lazarevic, S. (2010). “Changing Corporate Culture to Improve Business Performance: Case of the Australian,” Journal of Global Strategic management, 7, 53-63.

Publisher

Yusuff, R. M. (2004). “Manufacturing Best Practices of the Electrical and Electronic Firms in Malaysia,” Benchmarking: An International Journal. 11, 361-369.

Publisher

Zikmund, W. G. (2003). Business Research Methods (7th ed.). Ohio: Thomson South Western.

Publisher – Google Scholar