Introduction

The process of diversifying production should be properly planned and realized in a controllable way. It is important to find an appropriate business reason and develop a strategy for actions, which should precede and shape the planning of operational activities. Success on new markets is accompanied by a high risk of failure; therefore, it is extremely significant to carry out a detailed analysis of all factors of varying impact on actions and to properly manage all major threats (Chauhan et al., 2018). The aim of the present research was to identify and assess the risk of implementing a product innovation in an enterprise from the oil production industry, as well as to plan actions related to unacceptable risks.

Risk Management

It is commonly believed that most actions are taken in the uncertain circumstances of changeability and unpredictability of the organization’s context (Korombel, 2017). Moreover, it is also assumed that uncertainty is a type of a concrete risk (DSDM Consortium, 2010). The ISO 31000 standard defines risk as the effect of uncertainty on objectives and emphasizes the role of managing diverse risks (ISO 31000). On the other hand, within agile management, risk is understood as an occurrence or a set of uncertain occurrences, which, if materialized, have a negative impact on achieving the planned objectives. It is also important that risk related to the actions taken by the organization does not only generate threats, but also creates opportunities (Hopkin, 2018). Thus, not only does risk assessment support managerial decisions within mitigating risks but also helps to identify the strengths of the project. It is commonly assumed that risk is a combination of the likelihood of an expected event’s occurrence (both negative and positive) and the scale of the potential impact on objectives (Hillson, 2009).

The conception of risk management was initiated by the insurance industry at the turn of 1940s and 1950s and was gradually adapted in other areas of management, which is confirmed by numerous publications from this period (Beck da Silva Etges and Cortimigila, 2019; Cagliano, Grimaldi and Rafele, 2014; Cole,Gine and Vickery, 2017; Hoseini, Hertogh and Bosch-Rekveldt, 2019; Shah, Etienne, Siadat and Vernadat, 2017). The core of risk management is the systematic, punctual and structured decision-making in uncertain circumstances, which consists in the identification of possible threats, as well as taking preventive and corrective actions. Therefore, risk management requires the elasticity of realized actions, adapting to the ongoing changes of structures, processes and knowledge level.

All these measures aim at minimizing negative effects of threats related to the actions taken by the organization (Aven, 2016). Managing risk in a project is commonly divided into six basic stages, including (1) risk management planning, (2) risk identification, (3) quality risk analysis, and (4) quantity risk analysis, (5) planning risk mitigation actions, (6) risk monitoring and controls (Hopkin, 2018; Hoseini, Hertogh and Bosch-Rekveldt, 2019). It is also reflected in the risk management model described in the ISO 31000 standard, which states that risk management should embrace determining the context, risk assessment (risk identification, analysis and evaluation) and risk treatment (ISO 31000). The risk assessment process should result in selecting a specific strategy for risk treatment mainly from the following options:

- avoidance – changing the conception of operation,

- transfer – delegating the realization of certain actions to external entities,

- mitigation – taking proper actions, which aim at reducing negative effects of the materialized risk,

- acceptance – accepting the existing risk and acting in uncertain circumstances (Crispim, Silva and Rego, 2019).

The complex and correct risk management in a project or an organization brings many tangible benefits. The most obvious of them include increasing the likelihood of achieving business objectives, improving the decision-making process, and boosting the efficiency of resource allocation. Consequently, risk management should be reflected in cost reduction, shorter time of implementing changes, bigger sense of control over subsequent stages of the project, and preparedness for the occurrence of potential threats (Aven, 2016; Hillson, 2009).

Risk Management in The Food Industry

The food product market undergoes constant evolutionary changes. Even the best-prepared and realized expense and price strategy stops bringing the expected results due to the decreasing role of price as a determinant of consumers’ purchasing decision. Consumers’ awareness and knowledge are incessantly growing, which is accompanied by the rising expectations towards food products reflected best in the cyclical consumption trends (GlobalFoodForums®, 2019; Giampietr et al., 2018). The crucial condition of gaining competitive advantage is innovativeness. However, it is mostly evolutionary (and not revolutionary), which means that the food market is full of similar products, differing in flavor, form of sales and packaging. The analysis of specific segments of the food industry seems to indicate that the oil production industry is an area resistant to revolutionary changes. The biggest changes within the production technology and new products in this industry could be witnessed in 1990s and now the room for changes within raw material usage is very limited (Boczor and Błażejczyk-Majka, 2018; Chauhan et al., 2018).

The domestic market of edible oils, especially the cold pressed ones, has shown a growing tendency for the last decade, which has triggered considerable interest of researchers. Relevant studies include the quality evaluation of raw materials and final products, as well as increasingly often of byproducts (OECD/FAO, 2016). During the process of cold pressing a significant amount of pomace, i.e. the remaining part of oily raw materials from which the proper oil has been extracted by means of mechanical methods, is created. Numerous studies indicate that oil production waste is a rich source of nutrients and can be successfully used in other branches of the food industry, e.g. in bakery and confectionary, without any threat to health (Coelho & Salas-Mellado, 2015).

Among the main advantages of the further use of pomace as byproducts, we may point out the reduction of post-production waste treatment costs and the potential profit from selling press cakes as pomace flour. Sales of this product relate to entering new segments of the market and attracting new consumer groups. Such projects amount to an opportunity (and sometimes even a necessity) for small, family oil mills balancing on the verge of profitability (Bińczak, 2019).

Adapting production to the needs of the new undertaking does not have to be costly, yet, as any new project, entails some risk of failure. Therefore, it calls for the cluster analysis of all relevant factors and taking account of its results in the process of making managerial decisions.

Market risk in the food industry is mostly analyzed in the context of the assessment of the product’s impact on consumers’ mood and health. It is common to carry out the analysis of exposure to a given nutrient, its biological, chemical and physical safety, as well as to manage risk in the supply chain, i.e. from harvest to the final consumer’s purchase (Wrzosek et al., 2017). The approach to risk in the food industry is regulated by law, including the Regulation (EC) no. 178/2002 of the European Parliament and Council of 28 January 2002, which establishes general principles and requirements of the food law, as well as creates the European Food Safety Authority (EFSA). The regulation also contains food safety procedures related to risk analysis that guarantees the minimization of chemical, physical and biological threats of products (Rozporządzenie 178/2002). However, it should be noted that complex risk management of introducing a new product onto the market has been conspicuously absent in research.

Proper Research

The analysis was focused on a family enterprise from the oil production industry, which operates in the Kujawy-Pomerania Voivodeship and specializes in natural edible oils (a statistical oil company in Poland). The company described is J.A.W Łącz Przetwórstwo Roślin Oleistych-Nasiennictwo Ltd. It is a family company in the oil industry producing natural vegetable oils since 1992. The organization has full control over the production process, from sowing plants to harvesting raw material, oil pressing and distribution. The company specializes in cold pressing of edible oils from flax, hemp, sunflower and rapeseed. In addition, it produces oil cake, deoiled meal and firewood briquettes. It is a member of various organizations for organic, traditional and regional food producers. The amount of oil production is: rapeseed oil about 100,000 l, linseed oil about 20,000 l, sunflower 12,000 l, hemp oil about 2,000 l. Production structure: approx. 34% oil and 66% oil cake (data for 2017). Its offer includes both pressed oils – linseed oil, sunflower oil, hemp oil – and refined rape oil. The oils are sold in containers from 250 ml in the case of pressed oils to 5 l in the case of refined rape and sunflower oils. The average annual production volume reaches 20.000 l of linseed oil, 12.000 l of sunflower oil, and approx. 2.000-4.000 l of hemp seed. The efficiency of production is 30%. So far pomace has been sold to local farmers for approx. 4,70-10,70 PLN (1,10-2,50 EUR), while the price of raw materials was approx. 7,00-25,60 PLN (1,65-6,00 EUR). The average price of the enterprise’s products was approx. 34,10 PLN (8,00 EUR) for sunflower oil, approx. 64,00 PLN (15 EUR) for linseed oil, and approx. 170,00 PLN (40 EUR) for hemp oil. The oil mill is not dependent on suppliers – raw materials are mostly obtained from farms belonging to the owners of the mill. Retail sales prevail and are realized through phone orders and the Internet service. The enterprise cooperates with several shops located in the same voivodeship in addition to its own shop.

In light of the growing competition and limited technological capacity not allowing to enlarge the present production volume, the enterprise looks for new forms of activity, including the ones involving the rational use of treating byproducts that cannot be transferred to local farmers and breeders. The enterprise has already made the decision about broadening its product portfolio with pomace flours created in the process of milling press cakes, which are obtained in pressing oils. Moreover, the enterprise plans to continue the strategy of selling products in its online shop.

The aim of the present research was to identify and assess the risk of implementing a product innovation in an enterprise from the oil production industry, as well as to plan actions related to unacceptable risks.

Research Method

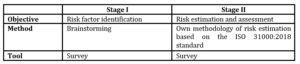

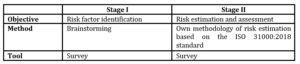

The research was carried out in two stages (Table 1). The first stage consisted in brainstorming in the group of 10 persons (top management, relevant employees and the present paper’s authors). In this way the risk factors of commercializing a new product in the oil production industry were identified. The process was founded on the determined context of the organization, its experience, market observations and relevant professional literature. Next (stage 2), the risks attached to each of the identified factors was estimated with the use of our own methodology prepared in accordance with the ISO 31000 standard. This stage aimed at determining risk gradation, indicating priorities in relation to mitigation actions and opportunities.

Table 1: Research characteristics

Source: own research

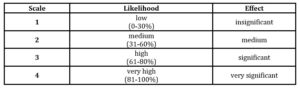

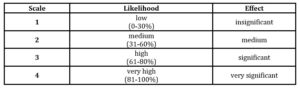

In the present study, we calculated risk by multiplying the likelihood of a detected event’s occurrence and the size of its impact on realizing the planned objectives (effect) by each other. Due to the fact that the ISO 31000 standard does not define a specific methodology of attaching value to risks, i.e. guidelines for risk criteria and their values, in the present study we used the matrix method for risk estimation with the use of the scale ranging from 1 to 4 (Table 2.).

Table 2: Risk estimation measures

Source: own research

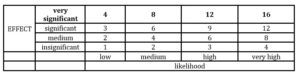

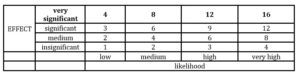

Risk levels for specific factors were calculated by multiplying Likelihood and Effect of the occurrence by each other (Table 3).

Table 3: Risk estimation matrix

Source: own research

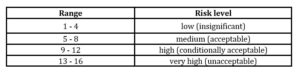

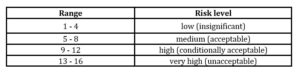

Next, on the basis of the obtained value the risks were classified into one of the four groups – insignificant, acceptable, conditionally acceptable, and unacceptable (Table 4.).

Table 4: Classification of risks according to importance

Source: own research

The statistical analysis of the results was carried out with the use of IBM SPPS Statistica. Basic statistical measures, including the average and standard deviation, were calculated.

Research Results

Risk Factor Identification

The basis for identifying the main risk factors of expanding production and entering a new market segment was the SWOT analysis, which was used to determine and classify all internal and external factors with impact on the current and future situation of the organization taking account of the organization’s market position and its micro- and macrocontext. While defining internal factors, the following aspects were considered: groups of resources, i.e. personnel, financial resources, knowledge and infrastructure, sales, customer service, logistics, the applied technology, capacity for development, and business process realization tools.

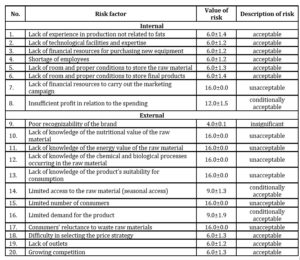

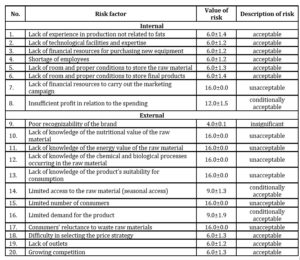

The first stage resulted in the list of 20 risk factors referring to the market situation, the product’s specificity and the enterprise’s experience (Table 5).

Risk Estimation

The risk factors defined at the first stage of the research were then subjected to assessment in the context of the likelihood of occurrence and the impact scale. The estimation was carried out within the same team of 10 persons, who identified the factors. The discussed results amount to the average of values given by each research participant (Table 5).

Table 5: Risk factors for the process of implementing a product innovation

Source: own research

Respondents displayed large consistency of estimation despite the fact that the assessment was carried out individually. Seven risks were identified as unacceptable, 3 – as conditionally acceptable, 9 – as acceptable, and 1 – as insignificant. The low level of consumers’ and food producers’ awareness of the nutritional values of pomace flours was considered the most important and dangerous factor for the project’s success. The expected effect of it is reluctance to the designed product and the fear of lack of demand that would assure the return of the incurred costs and obtaining income at the assumed level. The factors related to the lack of the enterprise’s knowledge and experience were considered important. For example, they included difficulty with estimating the expiry date of the product, the necessity to adjust production and employ new workers, which can be problematic when balancing on the verge of the existing production’s profitability. The factors linked with the internal adaption of the enterprise to the new production technology were considered less significant due to the fact that it is relatively simple and the enterprise has some resources, as it sells press meal for fodder.

Mitigation Actions

In professional literature it is hard to find any information on the complex risk estimation in the food industry in the context of commercializing new products. It can stem from the interdisciplinary character of our research and the focus on the product itself (and not the accompanying factors). However, the necessity to carry out risk assessment in relation to product quality, including its safety and availability, is strongly emphasized in relevant papers. In order to minimize risk and increase the probability of the project’s success, the enterprise should launch cooperation with a research unit, which is able to conduct complex research in the nutritional and energy value of press cakes as well as to assess their suitability for consumption and the dynamics of chemical and biological processes occurring during storage. This knowledge may become a major asset in advertising campaigns and will allow to reduce costs related to conducting research with the use of one`s own resources, including employing new personnel. In addition to nutritional aspects, the advertising campaigns should stress the environment-friendliness of using press cakes, as consumers increasingly often take it into account. Not only does the cooperation with a research unit boost credibility but also allows for presenting the product at conferences and finding its new applications.

The factors, which were considered crucial in the context of the project’s success, mainly stem from the demand for the product at the insufficient level and, consequently, the relevant low income from sales. It seems that at initial stages the enterprise should focus on intensified marketing and advertising activity targeted on its existing clients. Making better use of the enterprise’s website and social media accounts appears to be a highly efficient and cost-free tool in such a situation. These communication channels allow for the direct contact with the consumer, personalized messages and publications. In order to strengthen the message and credibility it is useful to invite a person, who is involved in research in nutrition, and an expert, whose studies focus on the use of waste in the food production, to join the advertising campaign. Once the product is established in the consumers’ awareness and the number of rival products is bigger, the enterprise should reconsider the expense and price strategy based on the in-depth analysis.

It should be noted that the general risk related to the production and implementation of pomace flours can be automatically reduced by the changes on the food market and in the consumers’ awareness. For the last several years, we have observed a shift from the highly-processed food to natural products of high nutritional value. The demand for new gluten-free raw materials (as well as interest in them) has also been growing (GlobalFoodForums®, 2019). Moreover, the need to implement eco-friendly actions, e.g. rational waste treatment (in compliance with the zero-waste policy) and minimization of food waste, has been increasingly emphasized.

The abovementioned questions of designing and implementing innovation on the food market should not be discussed only in the context of maintaining the nutritional and health safety of the new product, as it is recommended to take into account all factors that have impact on the whole project from planning to commercializing and selling the product. The analysis of professional literature within the scope risk management in the food industry indicates two main trends. The first one relates directly to the risk of maintaining the food product’s safety, including allergens, durability, vulnerability to microbiological, physical and chemical contamination, as well as the risk in the supply chain (Prakash et al., 2017; Kassie et al., 2014). The other trend is centered on the last phase of the project, i.e. the risk assessment of consumers’ reluctance to accept the product, failing against the strong competition of substitute products, and the insufficiently long (in comparison with expectations) product life cycle (Białoskurski, 2018; Fuller, 2016). In addition, some papers touch upon the questions of risk management in projects linked with the implementation of new technologies and machinery, which engages the enterprise’s resources and requires large spending (Arrenvalagan and Mohamed, 2016, Rezaee et al., .2018). In spite of different aims of applying risk assessment in the food industry projects, they share the common (and analogical to the results obtained in the present study) notion that efficient risk management in new projects is necessary to achieve goals in an efficient and effective way. Moreover, it allows for taking actions in controlled circumstances throughout the whole period of realizing the new project, as well as for taking immediate corrective actions or timely preventive actions (Beck da Silva Etges and Cortimiglia, 2019).

Summary

The process of commercializing a product innovation in an organization is always burdened with a high risk of failure, which calls for in-depth assessment, analysis and management. In the case of the discussed enterprise the biggest threat seems to be the origin of the raw material, which can discourage consumers, the uncertainty of outlets, or the limited human and financial resources, which significantly hinder efficient and memorable advertising campaigns on the national scale. Broadening the product portfolio preceded by risk assessment allows for taking account of all potential difficulties at the stage of planning. It enables the enterprise to properly prepare and increase its chances to succeed. The research also depicts that risk assessment does not have to engage a team of interdisciplinary experts, as it can be founded on the knowledge and experience of employees and careful observations of the macro- and microcontext of the organization.

References

- Arrenvalagan, K and Mohamed, Z. (2016), ‘Risk management in a large scale project of manufacturing industry,’ Proceedings of the 1st Master Symposium on Engineering Business Management, 13 December, 101-108.

- Aven, T. (2016), ‘Risk assessment and risk management: review of recent advances on their foundation’ European Journal of Operational Research 253, 1-13.

- Beck da Silva Etges, AP, and Cortimiglia MN. (2019), ‘A systematic review of risk management in innovation-oriented firms.’ Journal of Risk Research 22 (3), 364-381.

- Białoskurski, B. (2018), ‘Wizerunek a innowacyjność współczesnych produktów żywnościowych,’ Handel wewnętrzny 3 (37), 59-69.

- Bińczak, O. (2019), Stabilność oksydacyjna frakcji tłuszczowej wytłoków z orzecha włoskiego w kontekście jego wykorzystania w przemyśle spożywczym. Praca doktorska. Poznań: Uniwersytet Ekonomiczny w Poznaniu.

- Boczor, P., Błażejczyk-Majka, L. (2018), ‘Konsumenci oleju rzepakowego a konsumenci oleju słonecznikowego w Polsce,’ Handel wewnętrzny 2 (373), 90-103.

- Cagliano, A.C., Grimaldi, S. and Rafele, C. (2014) ‘Choosing project risk management techniques. A theoretical framework,’ Journal of Risk Research 18 (2), 232-248.

- Chauhan, A.S., Nepal, B., Soni, G and Rathore, PS. (2018), ‘Examining the State of Risk Management Research in New Product Development Process,’ Engineering Management Journal 30, 85-97.

- Coelho, M. S. and Salas-Mellado, M.D.L.M. (2015), ‘Effects of substituting chia (Salvia hispanica L.) flour or seeds for wheat flour on the quality of the bread,’ Food Science and Technology 60, 729-726.

- Cole, S. X. Gine, and J. Vickery. 2017. ‘How does risk management influence production decisions? Evidence from a field experiment.’ The Review of Financial Studies 30 (6): 1935-1970.

- Crispim, J. Silva, LH. and Rego, N. (2019), ‘Project risk management practices: the organizational maturity influence,’ International Journal of Managing Projects in Business 12 (1), 187-210.

- DSDM Consortium, 2010. Agile Project Management. Handbook, Headley Brothers Limited, United Kingdom.

- Fuller, G.W. (ed). 2016. New food product development. From Concept to Marketplace. Third Edition. London: CRC Press Taylor & Francis Group.

- Giampietri, E., Verneau, F., Del Giudice, T., Carfora V. and Finco, A. (2018), ’A theory of planned behavior perspective for investigating the role of trust in consumer purchasing decision related to short food supply chains,’ Food Quality and Preference, 64, 160-166.

- GlobalFoodForums® https://www.globalfoodforums.com [Retrieved July 13, 2019].

- Hillson, D. (ed). 2009. Managing risk in project. London: Routledge [Online]. Doi: https://doi.org/10.4324/9781315249865

- Hopkin, P. (2018). Risk Management. Understanding, evaluating and implementing effective risk management. Croydon: CPI Group (UK).

- Hoseini E., Hertogh, . and Bosch-Rekveldt, M. (2019), ‘Developing a generic risk maturity model (GRMM) for evaluating risk management in construction project,’ Journal of Risk Research, 1-20.

- ISO 31000:2018. Risk management – Principles and guidelines. International Standard Organisation.

- Kassie, M., Teklewold, H., Marenya, P., Jaleta M. and Erenstein, O. (2014), ‘Production risk and food security under alternative technology choice in Malawi: application of multinominal endogenous switching regression,’ [Online] Journal of Agricultural Economics doi: https://doi.org/10.1111/1477-9552.12099

- Korombel, A. (2017), ‘Identyfikacja korzyści z zarządzania ryzykiem I wyznaczania apetytu na ryzyko w małych I średnich przedsiębiorstwach,’ Zeszyty Naukowe Politechniki Śląskiej. Organizacja i zarządzani 114, 231-24.

- OECD/FAO. (2016), ‘Oilseeds and Oilseed Products’. in: OECD-FAO Agricultural Outlook 2016-2025, 101-125. Paris: OECD Publishing.

- Rezaee, M.J., Yousefi, S., Valipour, M. and Dehdar, MM. (2018), ‘Risk analysis of sequential proces in food industry integrating mulit-stage fuzzy cognitive map and proces failure mode and effects analysis,’ Computer & Industrial Engineering 123, 325-337.

- Rozporządzeniem (WE) nr 178/2002 Parlamentu Europejskiego i Rady z dnia 28 stycznia 2002 r. ustanawiającego ogólne zasady i wymagania prawa żywnościowego, powołującego Europejski Urząd ds. bezpieczeństwa Żywności oraz ustanawiającego procedury z zakresy bezpieczeństwa żywności.

- Shah, L.A., Etienne, A., Siadat, A. and Vernadat, F. (2017), ‘Process-oriented risk assessment methodology for manufacturing proces evaluation,’ International Journal of Production Research 55 (15), 4516-4529.

- Wrzosek, M., Bilska, B., Kołożyn-Krajewska D. And Krajewski. K. (2017), ‘Zastosowanie analizy ryzyka do opracowania innowacyjnego systemu ograniczania strat i marnowania żywności w handlu detalicznym (system MOST),’ Żywność. Technologia. Jakość 24 (2), 140-155.