Introduction

The issue of knowledge used in the enterprise has been addressed in many works and scientific research (Kogut and Zander, 1992; Grant, 1996; Nonaka and Peltokorpi, 2006; Dayan, et al., 2017) which only emphasize its importance for the functioning of modern enterprises. However, the conducted research also indicates that it remains a resource that is not sufficiently used in everyday business practice (Dayan, et al., 2017). This is emphasized also by J. R. Pfeffer and Sutton (2002) who believe that in the everyday functioning of enterprises there is a significant divergence between possessed knowledge and skill of its applications (Gierszewska, 2003). The reason for this may be the lack of proven models and procedures that can be directly used to manage knowledge (Gierszewska, 2003). The knowledge of the enterprise is perceived as an element of business management (Dayan, et al., 2017), a source of permanent competitive advantage (Nonaka and von Krogh, 2009), the determinant of innovation and the main factor of socio-economic development.

Knowledge integration in organizations may occur through organizational routines (Schuitz, 1999), direction (Conner and Prahalad, 1996), or processes involving the sharing of explicit or implicit knowledge (Grant, 1996). Effective knowledge management (KM) is considered key to the success of contemporary organizations (Dayan, et al., 2017). Some authors view organizations as distributed knowledge systems (Tsoukas, 1997), streams of knowledge (Von Krogh, et al. 1994), and systems of distributed cognition (Boland and Tenkasi, 1995), wherein individuals act autonomously while understanding their interdependence with others.

Despite the high interest in the problems of knowledge, there is still a lack of clear, unified foundations in KM. In the study, authors will focus on the production enterprise that uses additive technologies (AM). Despite the fact that AM technology has been known since the 1980s, there is a lack of research and development on KM in such a specific, ever-growing productive branch. The dynamic development of this technology makes that knowledge in such enterprises is usually individualized and difficult to specify. The research will be described in the form of a case study. The aim of the article is the analysis of the process of KM at the operational level in the manufacturing enterprise of high-tech sector, which produces machine parts using additive technology (AM).

Knowledge in the Enterprise – the Theoretical Basis

Despite many studies on knowledge, it has not yet been clearly defined. Nonaka (2006) proves that knowledge is definitely different from data and information (Nonaka and Peltokorpi, 2006). Data can be classified as raw numbers, images, words, and sounds derived from observation or measurement (Nonaka, Peltokorpi, 2006). The information contains data that are logically ordered. Therefore, in this case knowledge is understood as a combination of experiences, beliefs, engagement and information in a specific context (contextual information) and experts’ opinions (expert insight) (Nonaka and Peltokorpi, 2006; Tzortzaki and Mihiotis, 2014). Brooking (1996) advances academic insight by defining knowledge as information based upon which action is taken (Tzortzaki and Mihiotis, 2014). Knowledge will define what information is needed for this. In enterprises, knowledge is often reflected in the habits, practices or processes performed by employees, but also in documentation (Tzortzaki and Mihiotis, 2014).

The complex nature of knowledge has resulted in the creation of many taxonomies aimed at understanding the essence of this issue (Nonaka and Peltokorpi, 2006; Tzortzaki and Mihiotis, 2014). A very commonly used knowledge approach is the classification developed by Ryle (1949) dividing knowledge into knowledge-that, allowing knowledge of facts and rules, and knowledge-how, as the ability to take action (Kogut and Zander, 1992). Despite the high interest in the problems of knowledge, there is still a lack of clear, unified foundations in KM. In the study, authors will focus on the production enterprise that uses additive technologies (AM). Despite the fact that AM technology has been known since the 1980s, there is a lack of research and development on KM in such a specific, ever-growing productive branch. The dynamic development of this technology makes that knowledge in such enterprises is usually individualized and difficult to specify. The research will be described in the form of a case study. The aim of the article is the analysis of the process of KM at the operational level in the manufacturing enterprise of high-tech sector, which produces machine parts using additive technology (AM).

It seems important to pay special attention to its explicit and tacit division proposed by Michael Polanyi (1967), (Nonaka and von Krogh, 2009). Explicit[i] knowledge in the enterprise is precise and systematic knowledge (Grudzewski and Hejduk, 2002). It takes the form of documents, databases or information, which are used to manage the enterprise. It is relatively easy to pass it on to other employees. Tacit[ii] knowledge, despite the fact that it is dominant in enterprises, is often difficult to specify. And its transfer takes place verbally, usually in small groups through personal contacts (Grudzewski and Hejduk, 2002).

The Management of knowledge

Knowledge management in an enterprise, as well as knowledge itself, should be considered in many aspects, as they are fields covering various disciplines of science. For this reason, there is no uniform definition of this issue in the literature. Probst et al., (2002) define KM as an integrated set of actions that aim to properly shape knowledge resources (Proust, et al., 2002). While Bukowitz and Williams (2000) capture knowledge management in the context of a process that enables an enterprise to generate value from intellectual assets or other resources based on knowledge (Baxter, et al., 2007).

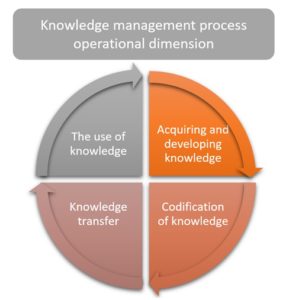

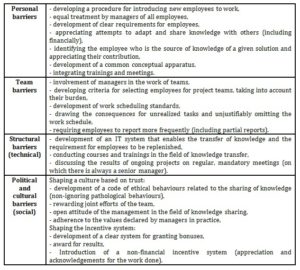

Knowledge management in an enterprise should be considered in both the strategic and operational aspects. The strategic dimension of KM includes primarily the construction of a knowledge-based organization, while the operational dimension is the acquisition of knowledge, its absorption and development (Mikuła, 2007). The knowledge management process presents figure 1.

[i] Also called a formal, objective, rational, conscious.

[ii] Called a quiet, intuitive, unconscious.

Fig. 1: Knowledge management process

Source: Own elaboration based on Mikuła, B. (2007), Od strategicznego do operacyjnego zarządzania wiedzą, Zarządzanie wiedzą. Wybrane problemy, Leja, K. and Szuwarzyński, K. (eds.), Wydawnictwo Katedra Zarządzania Wiedzą i Informacją, Politechnika Gdańska, Gdańsk.

Acquiring knowledge includes both activities focused inside and outside the organization. The internal streams of knowledge include analysis, reconstruction, synthesis, codification, modelling and organization of knowledge (Mikuła, 2007), or creating knowledge, externalization, selection, sharing, collecting, adopting, identifying (Mikuła, 2007).

Such knowledge is often obtained through the analysis of documentation, databases, books as well as contacts with co-operator. External orientation on acquiring knowledge will be related to the flow of knowledge from the environment to the enterprise, using cash flows and non-monetary flows – e.g. unpaid inter-organizational cooperation, competitions announced on the Internet, platforms for collecting ideas. Acquiring knowledge is also done through participation in training, conferences and symposia, as well as informally during contacts with other people (Mikuła, 2007).

The codification of knowledge by giving it a proper form will consist in gathering knowledge (notes, databases, archives, and electrical media) in order to make it available later to interested employees. This is currently of particular importance due to the increasing mobility of knowledge workers (laboratory employees, research and development departments, laboratories) often possessing key knowledge for the functioning of enterprises.

Knowledge transfer usually takes place through cooperation and communication between employees. The effectiveness of this process depends on the organizational culture prevailing in the company, including the level of mutual trust and the system of organizational language and the degree to which it is distributed among people (Mikuła, 2007).

The use of knowledge takes place in the company practically every day. In addition, the acquired knowledge can be used in the process of generating innovation.

Effectively conducted KM process may result in the increase of competences and skills of employees (Mikuła, 2007), saving time, human and financial resources (Dayan, et al., 2017 ) and increase in efficiency of management and innovation of the company (Dayan, et al., 2017).

Knowledge management in a production enterprise – a case

A case study approach was adopted in this research. According to Gerring and McDermott (2007), the case study approach represents an analysis in which one or a few units are studied in detail in order to provide insight to a broader class of units (Gerring and McDermott, 2007). The analyzed enterprise operates on the Polish market in the sector of small and medium enterprises for 19 years. It deals with the production of parts for the customer’s order using additive technologies (AM). At the enterprise’s request, its name will not be disclosed in the study. The analysis used the method of observation, analysis of documentation and interviews. In total 8 interviews took place, 6 with designers and machine operators to describe the part design process as it is actually used in an enterprise. Two interviews were conducted with production manager in order to obtain information on the logistics chain and work organization of the production department. Observation of the technological process from design to shipment took 7 days. The analysis also covered the available documentation on materials, machines, production processes, etc. It allowed to identify the existing knowledge in the enterprise, ways of its codification and transfer between employees and to identify problems in connection with its management. The researched entity specializes in plastic and metal prototyping products, through the processing methods of CNC machining, 3D printing (Selective Laser Sintering – SLS, Selective Laser Melting – SLM) and all kinds of post process treatments. The company’s international reach allows for the creation of innovative applications of additive technologies in the manufacturing industry.

Additive Technologies – Overview

Additive technologies (AM) consisting in the production of parts layer by layer through: melting of metal powders, sintering of polymers, extrusion of polymers, photo polymerization, etc. On the basis of the 3D computer model, layers corresponding to a fragment of a given thickness object are generated (Housholder, 1981; Kurzynowski, et al., 2010; Kurzynowski, et al., 2009; Madeja, 2014; Murr, et al., 2012). The digital layer model is passed to the AM machine control system. Then the material is applied to the model plate and locally remelt, in accordance with the shape of the generated cross-section. After completing this stage, the platform is lowered and the process is repeated until the complete model is created.

These technologies were initially used mainly for the production of prototypes designed to implement the concepts of designers and constructors. Along with their development and the development of new technical and material solutions, resulting in an increase in their universality, they began to be used in various industries such as medicine, art, architecture and the clothing industry. AM in many cases replace processes such as casting, machining, injection molding, etc. In manufacturing applications, AM is used in both unitary and small-volume production.

Description of the Manufacturing Process used in the Enterprise

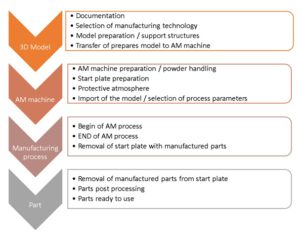

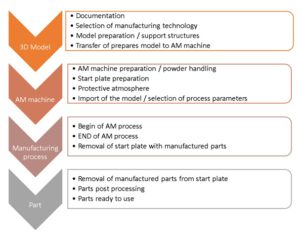

The process of manufacturing parts using AM (Fig. 2) begins with the customer providing a digital version, 3D model, of part. Depending on customer requirements, AM (SLS or SLM) technology is selected, as well as post-process machining. After selecting the technology, the model is converted to a file format accepted by the manufacturing device, checked for possible geometry errors, and modified if necessary. Modifications are always consulted with the client. After initial preparation of the model, it is virtually oriented and set in the working space of the AM device. Then, supporting structures are generated if required. The supporting structures have the task of maintaining the produced model in the working space of the device, reducing its deformation and also draining excessive heat.

The employee of the company selects the location and type of structures. In the next step, the file with model and supporting structures is transferred to the AM device. Parallel to this process, an AM machine is prepared.

The preparation process is as follows:

- determination of the available and required amount of material,

- preparation and loading of material to the device,

- preparation of a model platform and its installation in the working chamber,

- Preparation of a protective atmosphere.

After completing the preparation stage, the files with the model and supporting structures are imported to the device, then the correctness of their import is checked, and the files with the process parameters are selected for the models.

Fig. 2: Flow chart of manufacturing process used in the enterprise

Source: Own elaboration

After completing the preparation stage, the files with the model and supporting structures are imported to the device, then the correctness of their import is checked, and the files with the process parameters are selected for the models. The completion of this stage allows starting the manufacturing process. The device carries out the manufacturing process automatically until the complete part is made. After the process is completed, the following steps are carried out: removal of the powder from the chamber and the part, removal of the platform with the part produced, preparation of powder and equipment for the next process. Part is removed from the platform. In next step, also supporting structures are removed to prepare part for post-processing operations. For example, it could be machined according to the previously prepared machining plan in order to meet the requirements specified according to the documentation provided by the customer.

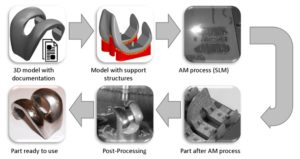

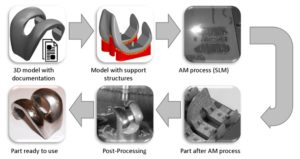

Figure 3 presents stages of preparation of part for the AM process (Madeja 2017). The first step in the manufacturing process was analysis of the documentation. It showed that the part must be made of a medical grade titanium alloy and also have high surface quality and high geometric accuracy. To meet the requirements related to this part, SLM technology and additional methods of post-processing, milling and grinding were selected. Additional post-processing steps were required because, despite that SLM technology allows producing complex shape part out of various metal alloys e.g. titanium, aluminium, steel, copper, cobalt, surface quality of produced parts is low (Ra 5-20µm) and also geometrical accuracy is in many cases insufficient (±0,5mm). In next step, the part was prepared to be manufactured in SLM technology. After completion of all stages related to SLM production, the part was milled and ground to obtain the final surface quality and geometric accuracy.

Fig. 3: Steps of manufacturing process on example of knee implant

Source: own elaboration based on Madeja, M. (2017), Wytwarzanie funkcjonalnych części maszyn za pomocą technologii generatywnych z uwzględnieniem obróbki powierzchniowej, Doctoral thesis

Analysis of Knowledge Management Status

Despite such a specific and innovative manufacturing process (requiring strict control and protection against competition), there are practically no knowledge management procedures at the operational level in the examined enterprise. The middle management staff does not engage in KM, leaving it to individual implementation for employees. There are also no formal solutions to save, collect, update and share knowledge about the processes being carried out. The problem is the organizational culture, focused on rivalry between teams and allowing theft or abuse (assigning the effects of the work of others). There is also a lack of the necessary infrastructure for sharing knowledge and the related incentive system.

The analysis of the generative process in terms of operational KM in the surveyed enterprise was presented below:

- Acquiring and development knowledge – this stage is important in many stages of the production process, i.e. choice of manufacturing technology, selection of process parameters and support structures, AM machine preparation and powders. In the analyzed enterprise device operation can be performed by a technician who acquires knowledge mainly through education and work experience. The choice of parameters is performed by the R&D department, which conducts its own research and acquires knowledge from outside, through participation in trainings and conferences initiated by the employee. He also uses professional literature. Acquired knowledge is individual and tacit.

- Codification of knowledge (following in the stage: choice of AM technology, selection of process parameters, supporting structures, process start, post-processing) – The codification of knowledge is performed primarily in the form of a register of activities performed on the device as well as reports and technical documentation after the completed process. However, the primary function of these documents is to inspect employees and possibly take consequences for an error, rather than sharing knowledge. The R&D Department also develops procedures for the selection of technologies and parameters, to maintain standardization and the appropriate quality of parts. However, it is knowledge available only to some employees of the department.

- Knowledge transfer (the whole process) – The transfer of knowledge takes place through regular meetings of employees regarding experience (and not procedures) from which no documentation is kept. The interested employees acquire knowledge individually to a different degree and scope. It is also not verified later.

- The use of knowledge (the whole process) – Knowledge is mainly used by machine operators and R&D department, which adapts the process to the clients’ requirements. The sellers who have direct contact with the client do not use the process knowledge because it is incomprehensible to them.

Individual employees of the enterprise acquire or create knowledge on their own. The most necessary knowledge for the efficient implementation of the manufacturing process is developed internally by the research and development department. R&D staff perceive knowledge as an element closely related to the competencies of a particular unit, which is why they do not pass it on. This results in the accumulation of knowledge that could be useful also in other departments (sales department, customer service, production department). Employees do not use each other’s experiences, incurring significant financial outlays and work to acquire the knowledge already accumulated in the enterprise. The knowledge codification stage is practically non-existent. Employees save documentation of completed projects on individual computers, using technical language, incomprehensible for other departments. There are no formal solutions to translate specialist knowledge into a language comprehensible to other departments. Transfer of knowledge takes place at team meetings, where mainly errors and future projects are discussed. Interested employees make their own notes. The acquired knowledge is used throughout the entire production process. The processes are relatively standardized due to the time and quality of manufactured parts. The problem is, however, to conduct the manufacturing process according to the individualized requirements of the clients or when the new solution is implemented on the market Appearing failures or complications are usually solved individually by the operators, only long-term stagnation of the device forces the inclusion of other employees of the company’s employees or servicemen from external organizations in solving the problems.

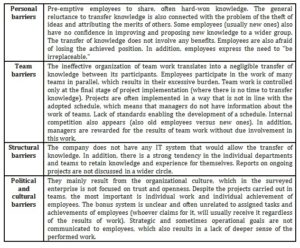

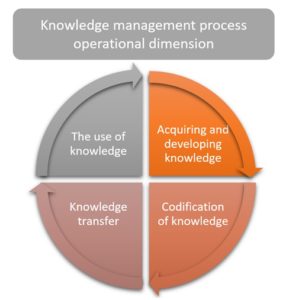

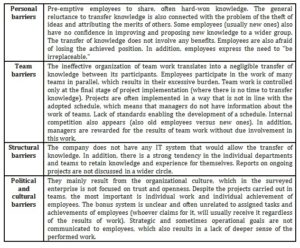

Analysing the KM process in a production enterprise, it is possible to identify several barriers and gaps in the flow of knowledge (Table 1).

Tab. 1: Barriers and gaps in knowledge management in the unit under study

Source: Own elaboration based on Kowalczyk, A. and Nogalski, B. (2007), Zarządzanie wiedzą, Koncepcja i narzędzia, Difin, Warszawa.

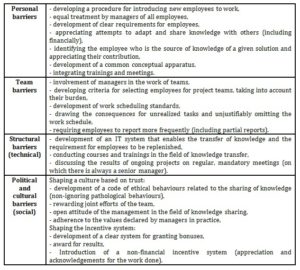

The operational level of knowledge management in enterprises is closely related to its strategic level. Therefore, most of the presented barriers result from improperly shaped organizational culture (unfavourable to expanding and sharing knowledge, lack of openness in communication) and organization of work (lack of incentive system and system for transferring knowledge, criticism of behaviour, theft of ideas that do not meet the reprimand from the superiors) of the company under study. Therefore, by constructing recommendations and guidelines to eliminate barriers, the strategic level of KM cannot be omitted (Table 2).

Tab. 2: Recommendations to eliminate barriers

Source: Own elaboration

The most important change should start with the attitudes and behaviors of the company’s managers. According to the principle that “the example goes from above”, they should be primarily consistent in their activities but also involved in the work of teams, because they are rewarded for the results of their work.

Research Findings

The globalization processes and the resulting growing customer requirements as well as dynamic market changes cause that the main goal of enterprises is to gain a competitive advantage. In addition, the turbulence of the environment causes changes in conditions for new products or innovations, especially in technology, which begin to largely be based on knowledge from the environment adapted to the enterprise. In these conditions, especially for small and medium-sized enterprises, KM (possessed and acquired) becomes crucial. The ability of enterprises to generate, collect, adapt new knowledge often determines its survival or development, which is why KM is included in the strategy of enterprises. Properly managed knowledge will be a source of permanent competitive advantage (Nonaka, von Krogh, 2009) or the determinant of innovation. However, this is not the case for the surveyed enterprise, where managers do not yet see the potential of knowledge management.

The aim of the article was the analysis of the process of KM at the operational level in the manufacturing enterprise of high-tech sector, which produces machine parts using additive technology (AM). A further intention was to find barriers and gaps in knowledge management at the operational level (as part of a specific process) and ways to overcome them. It should also be noted that the research did not analyze the quality of information or knowledge, which is of great importance at the time of using the knowledge already collected and decidedly less during its transfer.

The results of the research indicated a number of problems in four, adopted by the authors of the study, categories of barriers: personal, team, structural, political and cultural barriers. The most important of them are the limitations resulting from the organizational culture and management (social and technological barriers). This is also confirmed by numerous studies stressing that the success of initiatives related to knowledge management will depend on the cultural, structural and technological aspects of the culture, centralization structure and IT support (Oufkir L., et.al., 2017, Ale , et al., 2014: Wong et, al., 2013).

Conclusion

Despite the fact that knowledge management in the studied enterprise was to be analysed only at the operational level, its strategic level cannot be neglected. This level will include mainly changes in organizational culture and management. The operational level of knowledge management requires, above all, the development and implementation of a computer system that enables the collection and transfer of knowledge between the company’s cells. Knowledge management at the operational level requires a significant involvement of mid-level managers (Mikuła, 2007) in this process. Their role is above all to support employees and provide them with adequate infrastructure for communication and exchange of experience. In the literature on the subject there are many proposals for IT systems enabling the exchange of knowledge among others Guerra-Zubiaga and Young (2008); Young et al., (2007); Maropoulos et al., (2002); Baxter, et al., (2009). However, one of the most suitable systems for the studied enterprise is the solution proposed by Bruno et al., (2016) used to collect, store and transfer knowledge concerning only the production process (and all subprocesses necessary to implement it) (Bruno, et al., 2018). It therefore covers the operational level of the company. The proposed IT system will enable the collection of three types of knowledge: process knowledge, product knowledge, and task knowledge (Baxter, et al., 2007). Product knowledge concerns the best way of designing and manufacturing ordered parts, taking into account the client’s requirements. In this case, a thorough knowledge of the product, its purpose and experience in the design and realization of the production process is required. The sequence of activities to produce the required product function in the most effective way includes knowledge of relationships between product components, parameters, and materials. In the case of product knowledge, information and data on its geometry, expected parameters and purpose will be necessary. Knowledge of tasks includes formal design documentation and catalogues with the product specification. Such an IT system will ensure data consistency, enable obtaining them from previous production processes and re-use them.

In the surveyed company, employees share knowledge occasionally and reluctantly. This is directly related to the organizational culture prevailing in the company, which is not conducive to building trust and open social relations (there were thefts of ideas, which did not meet with the reaction of the superiors). Knowledge management in an enterprise is informal and, in principle, the stage of knowledge codification is omitted. This results in cost and time-consuming in re-discovering once acquired knowledge.

Properly managed knowledge will be a source of permanent competitive advantage (Nonaka and von Krogh, 2009) or the determinant of innovation. Therefore, it is extremely important to manage this aspect of the company’s operation, especially in sectors with rapid technological development, in which the interruption on the market is often determined by the use of emerging opportunities.

The research results of the authors of the study are important in two aspects: firstly, through the analysis of knowledge management elements in the additive manufacturing process (allow manufacturing complicated parts, process hard-to-machine materials, etc.), which may contribute to building a knowledge management model in the future enterprises using this technology; secondly, filling the gap in the literature on the lack of practical guidance for managers of high-tech companies, which will indicate that KM is a socio-technical process. Therefore, shaping the appropriate organizational culture and the implementation of a functional IT system is necessary for this management. In addition, properly developed guidelines for KM will have practical implications for an increasingly numerous group of companies using AM processes in production. The difficulty in KM is in this case the process itself, which covers issues related to the design of parts, metallurgy, metal processing, machining, postprocessing, etc. and the evolutionary nature of knowledge.

The study is limited due to its scope (one enterprise and one type of process) and the methodology of data collection, which is why the collected results cannot be generalized. Future research should be carried out more comprehensively (analyzing the strategic, tactical and operational level of KM in an enterprise). In addition, the analysis should cover a larger number of enterprises from the high-tech sector, which will enable statistical analysis. Only such a result will give a generalized view of this phenomenon. In addition, the direction of future research should also be to confirm the effectiveness of the proposed ways of overcoming the observed barriers.

(adsbygoogle = window.adsbygoogle || []).push({});

References

- Ale, M., Toledo, CM., Chiotti, O. and Gali, MR. (2014), ‘A Conceptual Model and Technological Support for Organizational Knowledge Management,’ Science of Computer Programming, 95 (1), 73–92.

- Baxter, D., Gao, J., Case, K., Harding, J., Young, B., Cochrane, S. and Dani S. (2007), ‘An Engineering Design Knowledge Reuse Methodology Using Process Modelling,’ Research in Engineering Design 18 (1), 37-48.

- Baxter, D., Roy, R., Doultsinou, A., Gao, J. and Kalta M. (2009), ‘A knowledge management framework to support product-service systems design,’ International Journal of Computer Integrated Manufacturing, 22 (12), 1362-3052.

- Bruno, G., Taurino, T. and Villa, A. (2018), ‘An approach to support SMEs in manufacturing knowledge organization,’ Intell. Manuf. 29, 1379–1392.

- Boland, R.J. and Tenkasi, R.V. (1995), ‘Perspective making and perspective taking in communities of knowing,’ Organimtion Science 6 (4), 350-372.

- Bukowitz, W.R. and Williams, R.L. (2000), The Knowledge Management Fieldbook. Financial Time, Prentice Hall, London.

- Conner, K.R. and Prahalad, C.K. (1996), ‘A resource-based theory of the firm: knowledge versus opportunism,’ Organization Science 7 (5), 477-501.

- Dayan, R., Heisig, P. and Matos, F. (2017), ‘Knowledge management as a factor for the formulation and implementation of organization strategy,’ Journal of Knowledge Management 21 (2), 308-329.

- Gerring, J. and McDermott R. (2007), ‘An Experimental Template for Case Study Research,’ American Journal of Political Science 51 (3), 688–701.

- Gierszewska, G. (2003), Budowanie strategii zarządzania wiedzą w przedsiębiorstwach, Zarządzanie wiedzą we współczesnych organizacjach, Kisielnicki J. (ed.), Wyższa Szkoła Handlu i Prawa im. Łazarskiego. Monografie i Opracowania (4), 62-88, Warszawa.

- Grant, R.M. (1996), ‘Prospering in dynamically-competitive environments: organizational capability as knowledge integration,’ Organization Science 7 (4), 375-387.

- Grudzewski, W.M. and Hejduk, I.K. (2002), Kreowanie systemów zarządzania wiedzą podstawą dla osiągnięcia przewagi konkurencyjnej współczesnych przedsiębiorstw, Przedsiębiorstwo przyszłości – wizja strategiczna, Grudzewski, W.M. and Hejduk, I.K. (eds.), Difin, Warszawa (2002).

- Householder, R. (1981), Molding process. [Online]. US Patent 4247508, Filed 3 December (1979), published 27 January [8.10.2018]. Available: https://patents.google.com/patent/US4247508B1/en.

- Kogut, B. and Zander, U. (1992), ‘Knowledge of the Firm, Combinative Capabilities, and the Replication of Technology,’ Organization Science 3 (3), 383-397.

- Kowalczyk, A. and Nogalski, B. (2007), Zarządzanie wiedzą, Koncepcja i narzędzia, Difin, Warszawa.

- Kurzynowski, T., Chlebus, E. and Dybała, B. (2010), Manufacturing customized products using selective laser melting technology, Kurzynowski, T., Chlebus, E. and Dybała B. (eds.), Anyagvizsgálók Lapja 4, 133-141.

- Kurzynowski, T., Chlebus, E., Kuznicka, B. and Dybała, B. (2009), SLM processing of metal powders. [Online]. Conference Proceedings ICMR09, The University of Warwick UK Management [8.10.2018]. Available: https://www.researchgate.net/publication/288571492_SLM_processing_of_metal_powders.

- Madeja, M. (2014), Wytwarzanie mechanizmów w technologii selektywnej laserowej mikrometalurgii proszków metali, Interdyscyplinarność badań naukowych, Szreka J. (ed.), Oficyna Wydawnicza Politechniki Wrocławskiej, 231-236, Wrocław.

- Madeja, M. (2017), Wytwarzanie funkcjonalnych części maszyn za pomocą technologii generatywnych z uwzględnieniem obróbki powierzchniowej, Doctoral thesis.

- Mikuła, B. (2007), Od strategicznego do operacyjnego zarządzania wiedzą, Zarządzanie wiedzą. Wybrane problemy, Leja, K. and Szuwarzyński, K. (eds.), Wydawnictwo Katedra Zarządzania Wiedzą i Informacją, Politechnika Gdańska, Gdańsk.

- Murr, L.E., Martinez, E., Amato, K.N., Gaytan, S.M., Hernandez, J., Ramirez, D.A., Shindo, P.W., Medina, F. and Wicker, R.B. (2012), ‘Fabrication of Metal and Alloy Components by Additive Manufacturing: Examples of 3D Materials Science,’ Mater. Res. Technol. 1 (1), 42–54.

- Nonaka, I. and Peltokorpi, V. (2006), ‘Objectivity and Subjectivity in Knowledge Management: A Review of 20 Top Articles,’ Knowledge and Process Management 13 (2), 73-82.

- Nonaka, I. and von Krogh, G. (2009), ‘Tacit Knowledge and Knowledge Conversion: Controversy and Advancement in Organizational Knowledge Creation Theory,’ Organization Science 20 (3), 635-652.

- Oufkir, L., Fredj, M., and Kassou , I. (2017). Performance Measurement for Knowledge Management: Designing a Reference Model [Online]. Journal of Organizational Knowledge Management [8.10.2018]. Available: https://ibimapublishing.com/articles/JOKM/2017/733562/733562.pdf.

- Probst, G., Raub, S. and Romhardt, K. (2002), Zarządzanie wiedzą w organizacji, Oficyna Ekonomiczna, Kraków.

- Schuitz, U. (1999), Investigating the contradictions in knowledge management, Information Systems: Current Issues and Future Changes, Larsen, T.J., Levine, L. and De Gross J.I. (eds.), Laxenburg, Austria.

- Stankiewicz, M. J. (2006), Zarządzanie wiedzą jako kluczowy czynnik międzynarodowej konkurencyjności przedsiębiorstwa, Towarzystwo Naukowe Organizacji i Kierownictwa “Dom Organizatora”, Toruń.

- Tsoukas, H. (1997), ‘The firm as a distributed knowledge system: a constructionist approach,’ Strategic Management Journal 7, 11-25.

- Tzortzaki, A. and Mihiotis, A.(2014), ‘A Review of Knowledge Management Theory and Future Directions,’ Knowledge and Process Management 21 (1), 29-41.

- Von Krogh, G., Roos, J. and Slocum, K. (1994), ‘An essay on corporate epistemology,’ Strategic Management Journal 5, 53-71.

- Wong, K.Y., Tan, L.P., Lee,SC. and Wong WP. (2013), ‘Knowledge Management performance measurement: measures, approaches, trends and future directions,’ Information Development, 31 (3), 239–257.