Introduction

Every day, organisations operating in the market face the challenge of meeting the expectations of their customers, employees, shareholders or further environment. On the one hand, they still want to improve their efficiency in performing routine activities, on the other, managers are aware of the need for continuous development and introduction of changes. This is urged by an increase in the level of employees’ qualifications and access to knowledge about new trends in management or technology. According to Fryer and Ogden (2014), many researchers believe that a modern organisation cannot build a high level of performance without a key ingredient that is, Continuous Improvement (CI). Swinehart, Miller and Hiranyavasit (2000) describe CI as the final ultimatum for building an organisation belonging to the ‘a World-Class’ group, while research on the application of the concept of continuous improvement in countries such as Japan, Australia, Sweden, Great Britain, Spain, Belgium or China confirm that it is implemented in enterprises worldwide, see Boer and Gertsen (2003), Marin-Garcia et al. (2008) and Dabhilkar et al. (2007). The introduction of improving technical, organisational and commercial changes means that to achieve them, it is necessary to implement well-organized and efficiently implemented new unique projects. Therefore, according to Bukłaha, Juchniewicz (2019), organisations increasingly combine two categories of activity: operational activities – process and routine, and project activities – related to innovation, change and transformation. The implementation of such projects requires special and time-limited organisational solutions within the existing structure of the organisation or outside of it, see Trocki (2012), which requires building an organisational capacity to find a balance between a repetitive activity and project activity called ‘ambidexterity’, see Zakrzewska-Bielawska (2016). Routine activity ensures its business continuity, and a design approach allows the transformation and development of the organisation, which must result from the adopted strategy. In the past, project management (PM) was closely associated with the civil and built environment and the defence industries. Nowadays, it is in common use in virtually all sectors of the economy, such as information technology (IT) and information systems, manufacturing (product innovation), finance and service industries, and arts and culture (events), see Abbasi, Jaafari (2018).

In this article, attention has been focused on organisations operating in the production industry, focused on the development based on the concept of continuous improvement. Its use entails the introduction of methodologies such as (e.g.): Kanban, Total Productive Maintenance (TPM), 5S and Total Quality Management (TQM), or further: Lean Manufacturing, Six Sigma and Lean Six Sigma. Organisations deciding to implement these types of methods require organisational support that will lead to coherent and logical actions at the stage of introducing and developing numerous new initiatives. This can be done by using project management methods and techniques. However, as the results of research conducted by Spałek (2014) among domestic enterprises operating in the engineering industry show, about 90% of them have only reached the second level of maturity in project management in individual areas of assessment, i.e. methods and tools, human resources, the design environment and project knowledge management. Although the area of methods and tools has proven to be the most mature, in 79% of the cases, it was similarly the second level. In the surveyed foreign enterprises, the area of methods and tools was also the most mature, in 55% of the cases, it was level 3. The level of application of project management and project tools was also examined in a group of small and medium enterprises operating in Europe. Conclusions from the conducted research indicate that such organisations require simplified versions of project management and uncomplicated sets of project management tools. According to Turner and Ledwith (2018), smaller companies indicate the need to use project management procedures adapted to smaller projects, while medium-sized enterprises most often use techniques such as: computer support through the use of the Microsoft (MS) Project software, Gantt charts, Critical Path Method (CPM) and value analysis.

Research Questions and Article Purposes

Continuous improvement of the organization requires the introduction of numerous changes of varying degrees of novelty and complexity. In this article, the authors decided to answer the following research questions: What are improvement initiatives projects? What are their characteristics? Which project management tools are useful for managing them?

The article aims to define and classify improvement projects and indicate techniques recommended in their management, and to present the role which they play in implementing the assumptions of continuous improvement in manufacturing companies. It is an important topic allowing for the elaboration of guidelines which would reduce the risk of errors in implementing improvement projects.

Research was conducted in two steps: using a literature review and reference to a case study (example) in which direct observation, a document analysis and a partially structured interview were applied. This approach results from the need for an in-depth analysis of the issue related to managing improvement projects especially in reference to empirical studies. Case studies are rarely found in subject literature. The example presented in the article aims to analyse improvement projects in a production enterprise pursuing the rules of CI and supplementing their characteristics and classification presented in the literature.

Literature Review

The link between Project Management and Continuous Improvement

According to Marin-Garcia, Pardo del Val and Bonavía Martín (2008), the CI concept is treated as a way to maintain and improve the organisation’s competitiveness by using the knowledge and commitment of all its employees. An analysis of the definition of ‘continuous improvement’ allows to conclude that it is connected with building a culture of lasting improvement, see Bhuiyan and Baghel (2005), as well as with launching a number of procedures enabling the organisation to improve what it is currently doing, see Bessant, Caffyn (2001). Brunet and New (2003), on the other hand, indicate that CIs are ubiquitous and continuous activities, beside the standard roles of the participants to identify and achieve results that contribute to achieving organisational goals. Bhuiyan and Baghel (2005) describe CI as an improvement initiative that increases success and reduces errors. The terms appearing here: ‘a number of procedures’, ‘activities outside the standard roles’ or ‘initiatives’ indicate the link between CI and the need to launch various types of projects that allow the implementation of the concept’s assumptions. Despite the fact that the definitions also emphasize that CIs are minor changes which do not require large investments, experience shows that a large amount of work and an organisational effectiveness are needed to launch a new way of thinking and the organizational capacity which could be obtained through the use of project management.

This need is undoubtedly enhanced after analysing a set of specific values, principles and numerous techniques recognized as basic CI practices. Sua´rez-Barraza, Ramis-Pujol and Kerbache (2011) listed the most important principles and values of CI:

- Maintaining and improving standards,

- Focus on processes,

- Improvement at Gemba level,

- Participation of all employees,

- Commitment of top management,

- Discipline and constancy of purpose,

- Ability to conduct experiments,

All of that in addition to the most important techniques: Total Productive Maintenance (TPM), Total Quality Control (TQC), autonomy, Single Minute Exchange of Die (SMED), PDCA (Plan-Do-Check-Act) cycle, SDCA (Standard-Do-Check-Action) cycle, activity of small employee groups, as well as so-called improvement teams, Kanban and Just in Time, Total Flow Management (TFM), inter-departmental management, 5S and elimination of waste, Gemba and visual management, Hoshin Kanri and zero defects.

They require the introduction of solutions that, in many cases, constitute a new challenge for organisations, e.g. TPM, Single Minute Exchange of Die (SMED) or Just in Time. Their implementation constitutes a sequence of unique, complex and related tasks with a common goal. The management’s intention should be to introduce them within a fixed time limit, without exceeding the set budget and, of course, in accordance with the assumed requirements.

This basic characteristic allows to recognise that these are projects which, before they become a permanent practice, must be wisely initiated and defined, planned, organized and implemented. Organisational errors at the implementation stage of these programmes are particularly risky, primarily due to the simultaneous development of the organisational culture and work environment, which in effect, can have a positive and negative impact on the environment.

However, it also turns out that research to identify errors of CI initiatives in manufacturing environments has shown that many of them relate to project management.

The results of the study carried out in enterprises which apply the design approach in improvement activity indicate that the most common errors are:

- Poor selection, see Gijo (2011) and Keim (2011) and project resources, see Snee (2010),

- Project selection is not aligned with the enterprise’s strategy, see Kornfeld and Kara (2013),

- Too large scope, see Hariharan (2006),

- Selection of inappropriate methods, see Kornfeld and Kara (2013),

- Assessment concerning the number of implemented projects as a measure of success, see Hariharan (2006),

- Slow pace of the project’s team work, interruptions in operation, poor selection and application of methods or tools, see McLean, Antony and Dahlgaard (2017),

- Duration of more than six months, infrequent team meetings or little technical support from Master Black Belt (or equivalent), see Snee (2010),

- Lack of analysis of the connection between the implemented project and the environment, see McLean, Antony and Dahlgaard (2017).

Further obstacles are identified in the project’s resources area:

- Selection of such people for the project teams who do not have enough time for this job, see Keim (2011),

- Too many project teams, see Snee (2010),

- Lack of involvement presented by team members, leadership deficiencies in the project or withdrawal of key people due to the pressure of current tasks, see Hariharan (2006),

- Team members’ turnover and shortage of access to key data, see McLean, Antony, and Dahlgaard (2017).

This means that introducing improvement initiatives is not an easy task, and that the errors mentioned are linked to many aspects of managing this type of project. Therefore, in order to enhance organization improvement, it is necessary to develop guidelines related to the management of improvement projects. However, it must be preceded by their characteristics and classification. This is an important task since it will facilitate the selection of methods and techniques appropriate to the scale and nature of the implemented project.

An organization operating in line with the CI concept quite often implements several improvement projects simultaneously, which also requires the use of techniques supporting the management of a project program. Martinsuo and Lehtonen (2007), in their research, noticed that the performance of a single project influences the final outcome of the group of projects realised in the company. There are factors which could be associated with managing a number of projects in parallel, which is more connected with project program management. The scope of project program management includes: creating a program strategy, project evaluation and creating a hierarchy, followed by the selection and management of active projects (projects which have been awarded funds). Therefore, according to Spałek (2012), it is necessary to select and use appropriate tools supporting the management of several projects simultaneously, which is the role of the project management office in enterprises operating in a multi-project environment. Techniques supporting project program management include: a dashboard, Gantt chart, task management, reporting, timesheets and planning. The most important task of each project is to achieve one basic goal and specific goals. The main goal must result from the adopted CI strategy and all projects should be implemented in a specific order. Undoubtedly, a project approach can be a great support in minimising the above-mentioned errors.

Definition and Characteristics of Improvement Projects

In the book by Kisielnicki (2011), a project is a broad concept and includes both the activity of creating new facilities and the modernisation of existing ones. It relates to organisational and technological changes, as well as those related to the introduction of new products to the market. Pawlak (2007) narrows this concept and presents the project as an undertaking implemented within a specific organisation, which is new, unusual and different from routine activities. Projects implemented by organisations operating in the socio-economic environment are characterized by very large diversity and at the same time there are many criteria according to which they can be classified. In the literature on the subject, among others, they were divided according to: fields, specifics, significance, scope, origin, result, innovation, range of size and orientation, see Trocki (2012), see Marek-Kołodziej and Łapuńka et al. (2017). Referring to the earlier definition of the project by Pawlak (2007), it was assumed that an improvement project is a unique undertaking, aimed at achieving the goal of improving the organisation and its processes; it is a sequence of completed and related activities. It is planned in time and has allocated resources necessary for its implementation. According to Wyrozębski (2014), it should be taken into account that a project is not a task that is too simple; it is a continuous activity that has no clearly defined purpose or scope and is part of an existing process. Therefore, it is worth specifying whether routine tasks or projects are discussed; a model is proposed in the literature to distinguish between them.

According to Jonsdottir, Ingason and Jonasson (2014), each statement for: limitations, execution and environment is given a grade from 1 to 10 and a total sum is calculated to discern if the subject is a project or not.

Statement for limitations:

- “There is ample time” or “There are time constraints”,

- “The subject is repetitive” or “The subject is unique”,

- “Not all phases are within the time frame from start to finish” or “All phases will happen within the timeframe from start to finish”.

Statement for execution:

- “The organisation’s processes are sufficient for handling this” or “Specific and appropriate processes are required”,

- “Participants have a similar background” or “Participants have a different background”,

- “All necessary knowledge is in one place” or “Extensive co-operation is needed”.

Statement for environment:

- “There is a low risk and predictability is high” or “There are multiple types of risk and/or opportunities”,

- “It will lead to minimal changes” or “It will lead to extensive changes”,

- “The environment has little effect on the results” or “The results are very much affected by the environment”

- “Those involved will be few and known” or “Many will be involved and not all known”.

If the total outcome is 60 or higher, there is a strong possibility that this is a project and PM methods need to be used.

The model indicates that the initiatives implemented under CI in many cases meet the project criteria since they correspond to the description in the right column of the table.

Classification of Improvement Projects

The analysis of literature on projects implemented as part of organisational improvement has allowed the selection of the following classification criteria:

- Project initiator,

- Improvement strategy adopted,

- Type of problem being solved,

- Organisation maturity, company age and process maturity and standardisation.

Projects may be initiated by top management, by middle management or by line employees.

In the book by Hamrol (2015), the division, adapted to the adopted improvement strategy and the type of issue, distinguishes four groups of improvement projects:

- Cleaning, oriented to organising the overall mess and organising the management system, recommended in TQM, Kaizen and Lean concepts,

- Eliminating waste, oriented to shortening the transition time, reduction of in-process stock or elimination of other types of waste, recommended in Lean concept,

- Quality improvement oriented to elimination of problems with meeting quality requirements, recommended in Six Sigma and Kaizen concepts,

- Searching for opportunities oriented to being better, recommended in Kaizen and Six Sigma projects.

The classification of projects is focused on improvement strategies such as: quality management (TQM, Six Sigma), Lean Management and Kaizen. However, when it comes to the types of issues to be solved, the following were distinguished: cleaning, eliminating waste, improving quality and searching for opportunities.

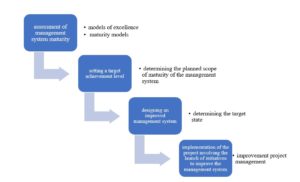

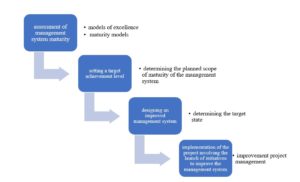

However, improvement projects can also be treated more universally – as an element of operation when designing an integrated business management system in a newly created enterprise, as well as in an enterprise that intends to improve its system. The design process for such projects can be summarized in four steps, which are shown in Figure 1.

Fig.1: The process of designing projects to improve the management system

Source: own study

Therefore, introducing improvement initiatives in the area of the management system functioning in the enterprise requires a design approach. Members of the team implementing this type of project may belong to the staff of a given enterprise or may also be external consultants. It is worth emphasising that as part of a single project to improve the current management system, challenges should be taken into consideration to overcome no more than one level of maturity, see Haffer (2011).

According to Hamrol (2015), the answer to the question of where the enterprise is at, in terms of the need to improve processes and resources, can be obtained by determining the age of the enterprise as well as the maturity of the processes and standardisation. Depending on where the organisation is at, improvement projects will be oriented towards:

- Introduction of basic standards – for young enterprises and immature processes,

- ‘System optimisation’, i.e. identifying issues and searching for opportunities for improvement for old enterprises and mature processes.

Improvement projects resulting from the assessment of management system maturity or process maturity and standardisation can be qualified as internal projects commissioned by the organisation’s management.

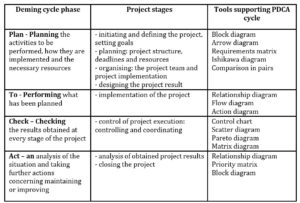

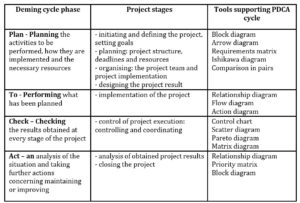

For their implementation, it is recommended to use the PDCA cycle, which consists of four phases: plan – do – check – act. In the case of improvement projects, these phases correspond to processes in the project management cycle and in the project life cycle (Table 1). The planning phase includes the stage of initiating and defining the project, planning its structure, organising and designing the project result. The project is being realised at the implementation stage. Checking is understood as a control, i.e. on-the-fly control along with the coordination of actions in case of any disturbances. The last phase is associated with an analysis of the results, closing the project if it is justified, along with the preparation of a report on the implemented activities also containing guidelines and recommendations for the future.

Table 1: Phases of PDCA cycle in combination with project stages and tools supporting its implementation

Source: own study

Table 3 also includes examples of tools supporting the operation of the PDCA cycle in its individual phases, which are useful of course during the implementation of the improvement project.

Improvement Projects Implemented in A Production Enterprise – An Example

Research on the implementation of the continuous improvement concept was conducted in a large enterprise producing electronic devices, including control elements with decorative elements. It is an experienced supplier of components for organisations producing household appliances which operates in the electrical and electronic industries. The organisation employs over than 900 staff members. There are 14 production lines in the plant, where serial production is carried out.

This case was chosen because:

- The company’s management has recognized the principles of continuous improvement as a major element of the organisation’s strategy, which gives rise to the analysis of the importance and place of project management in the implementation of its assumptions,

- The company management implements and applies all key practices of the CI concept in a thoughtful and orderly manner, which allows an observation and an assessment of their adaptation processes,

- A structured system of CI-related activities has been created in the enterprise, which eliminates randomness of implementing CI practices in the organisation,

- The enterprise has documentation confirming the CI practices used and projects implemented, which enables the use of documentation analysis.

The implementation of CI in the enterprise started with four projects:

- Launching a programme of improvement actions at the managerial and team level,

- Implementation of projects in the production area related to work standardisation, 5S technique and launching the flow of Kanban charts, carried out by the so-called permanent teams of continuous improvement,

- Launching a new organisational unit responsible for the continuous improvement programme in the enterprise,

- Launching a suggestion system.

The implementation of projects presented above took place in the first stage of introducing CI in the enterprise and was associated with a very high commitment of top management. Four stages were identified in their implementation: concept, planning, implementation and completion. They all had a specific goal, start and end dates and budget. A project team and its leader were appointed for all projects. The significance of the projects was very high both from the point of view of the operational objectives pursued and in relation to the new organisational culture in the enterprise which was shaped during this period.

The second stage in the concept’s development is continued implementation of activities in the field of continuous improvement teams and the suggestion system, as well as the introduction of a new approach to process improvement, based on the methods related to the implementation of Lean Manufacturing, including Total Productivity Maintenance (TPM), waste reduction, organisation of the suction production flow and value added analysis. This involved launching the implementation of many improvement projects, where the end of one involved the launch of the next. At the same time, projects aimed at improving employees’ qualifications were continued. Improvement projects were characterized by diversity and uniqueness. In many cases, they were created interactively through consultations and arrangements between top management and operational level managers.

In the third stage of the development of the continuous improvement concept, new improvement activities appeared in the enterprise, i.e. launching Lean activities also in the area of administration and development. Furthermore, the implementation of projects began in accordance with DMAIC (Define, Measure, Analyse, Improve and Control) characteristic of the Six Sigma strategy. It is clear and contains all stages resulting from the logic of proceedings when solving issues or achieving the set goals.

The summary and collective characteristics of the projects implemented in the specified three stages of the development of CI are presented in Table 2.

Table 2: Characteristics of projects implemented in three stages of CI development in the examined production enterprise

Source: Own study

The table also includes a list of practices and tools used in the enterprise to manage projects in the CI area, which involve:

- Defining the project,

- Project planning,

- Opening meeting,

- Formal assignment of resources to the project,

- Definition of target indicators,

- Project monitoring: reporting on the status of the project, approving the results,

- summary meeting,

- Project charter,

- Project schedule,

- Teamwork principles,

- Methodologies: PDCA, 8D and DMAIC.

The solutions adopted in the studied enterprise allow for a reduction in the number of duplicate errors in the implemented projects. Each project is defined and planned. Opening meetings, formally assigning resources to a project, defining indicators to monitor its effectiveness and approving results are a regular practice. Project schedules are also prepared, which facilitate reporting on the status of the project. One of the very good practices is keeping proper documentation (so-called project charter) and project coordination performed by the CI department. In a sense, it has become a project management office and a know-how base for ongoing projects. It also has responsibility for the flow of project information as well as the supervision and administration of the electronic database. Each project ends with a debriefing meeting during which the conclusions from its implementation are analysed, regarding both the purpose of the project and the experience acquired during its course.

Results and conclusion

The research carried out by the authors was divided into two stages. The first consisted of an analysis of the literature, which demonstrated that project management is particularly significant for enterprises operating in accordance with the CI approach. This entails the need to launch numerous projects as well as the need to apply project management techniques and their program.

Based on an analysis of the literature, the authors defined the concept of “improvement project” and selected the criteria for their classification. They also developed a juxtaposition of the PDCA cycle phases with project stages and tools supporting its implementation.

The particular significance of managing improvement projects was also confirmed by providing an example of a manufacturing company that has been operating in accordance with the CI concept for several years. Enterprise research has shown that most initiatives meet the project criteria in Table 2, and selected project management techniques are used to implement them.

A detailed analysis of the projects implemented in the company in three stages of the development of the CI concept allowed their characterization and identification of the applied practices and tools for project management.

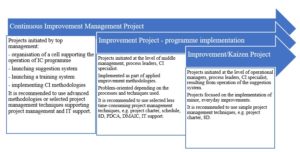

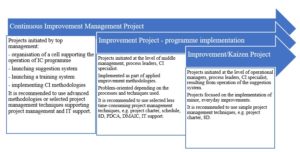

In summary, on the basis of research, improvement projects were divided into three groups:

- Projects initiated by top management in accordance with a top-down approach regarding the organisation of CI activities and the launch of further improvement programmes/methodologies, raising the level of the organisation’s maturity, with a greater range and level of advancement, unique but carried out according to a fixed plan, with a specified start and end date, pursuing a clearly defined goal; a project manager appointed by top management, requiring greater tangible and intangible resources;

- Improvement projects initiated by medium level managers and by the person responsible for the area of continuous improvement (specialist/leader for continuous improvement) of medium range and level of advancement, related to the applied improvement methodologies, unique but carried out according to a set plan, with a fixed start and end date, lasting for a maximum of 3 months, pursuing a clearly defined goal, initiated in accordance with a top-down approach or interactively, implemented by interdisciplinary teams appointed specifically for the project; requiring medium-level financial support;

- Kaizen projects (Improvement/Kaizen Project) aimed at implementing minor everyday short-term improvements, using low financial resources and using intuition, knowledge, skills and expertise gained in the workplace.

The proposed project characteristics are shown in Figure 2.

Fig. 2: Improvement project characteristics

Source: own study

It should be emphasised that the use of a design approach supports the implementation of the strategy adopted by the company and the subsequent implementation and application of CI principles and techniques. On the other hand, the description of ventures allows directing their leaders to the selection and application of methods and techniques of project management appropriate for the identified categories of improvement initiatives.

The limitation of the research lies in the fact that the results of the study are based on a single case study; therefore, caution is required before making generalisations on the basis of data. Further research is required to gather analysis results within a larger number of enterprises, which would lead to present more universal conclusions.

(adsbygoogle = window.adsbygoogle || []).push({});

References

- Abbasi,A. and Jaafari, A. (2018) ‘Evolution of Project Management as a Scientific Discipline,’ Data and Information Management, 6 (1), 91-102.

- Bessant, J., Caffyn, S. and Gallagher, M. (2001)‘An evolutionary model of continuous improvement behaviour,’Technovation, 21 (2), 67-77.

- Bhuiyan, N., Baghel, A. (2005)‘An overview of continuous improvement: from the past to the present’,Management Decision, 43 (5), 761-771.

- Boer, H., Gertsen, F. (2003) ‘From continuous improvement to continuous innovation, a (retro) (per)spective,’International Journal of Technology Management, 26 (8), 805–827.

- Brunet, A.P., New, S. (2003)‘Kaizen in Japan: an empirical study’,International Journal of Operations & Production Management, 23 (12),1426-1446.

- Bukłaha, E., Juchniewicz, M. (2019), ‘Key Challenges and Barriers and Trends in Project Management from the Point of View of Projects Implemented in Poland,’ Organization Review, (3), 14-20.

- Dabhilkar, M., Bengtsson, L. and Bessant, J. (2007) ‘Convergence or national specificity? Testing the CI maturity model across multiple countries’, Creativity and Innovation Management, 16 (4), 348-362.

- Fryer, K.J., Ogden, S.M. (2014) ‘Modelling continuous improvement in the public sector: key stages and indicators’Total Quality Management, 25 (9) 1039-1053.

- Haffer, R. (2011) Samoocena i pomiar wyników działalności w systemach zarządzania przedsiębiorstwem. W poszukiwaniu doskonałości biznesowej [Self-assessment and measurement of performance in enterprise management systems. In search of business excellence], Wydawnictwo Naukowe UMK, Torun.

- Hamrol, A. (2015) Strategie i praktyki sprawnego działania: Lean, Six Sigma i inne [Strategies and practices of efficient operation: Lean, Sic Sigme and others], PWN, Warsaw.

- Jonsdottir, S., Ingason, H. T., and Jonasson, H. I. (2014)‘Continuous improvement projects in certified organizations in Iceland: traditional projects or not?’, Procedia-Social and Behavioral Sciences, 119, 142-151.

- Kisielnicki, J. (2011), Zarządzanie projektami [Project Management], Wolters Kluwer SA, Warsaw.

- Marek-Kołodziej, K., Łapunka, I. and Wittbrodt P. (2017)‘Investigation to Establish Way of Management Large Projects in Production and Service Enterprises – Research Methodology’, [w:] Soliman K.S. (ed.), Vision 2020: Innovation Management, Development Sustainability, and Competitive Economic Growth, 29th International Business Information Management Association Conference, Vienna, Austria, May, 2017, 2662-2673.

- Marin-Garcia, J.A., Pardo del Val, M., Bonavıá Martín, T. (2008) ‘Longitudinal study of the results of continuous improvement in an industrial company,’Team Performance Management, 14 (1/2), 56–69.

- Martinsuo, M. and Lehtonen, P. (2007) ‘Role of single-project management in achieving portfolio management efficiency’, International Journal of Project Management, 25 (1), 56– 65.

- Pawlak, M. (2007), Zarządzanie projektami [Project Management], Wydawnictwo Naukowe PWN, Warsaw.

- Spałek, S. (2012) ‘The role of project management office in the multi-project environment,’International Journal Management and Enterprise Development, 12 (2),172-188.

- Spałek, S. (2014) ‘Assessing Project Management Maturity in the Area of Knowledge Management in Select Companies,’ International Journal of Economics, Finance and Management Sciences, 2 (2), 164-170.

- Sua´rez-Barraza, M. F., Ramis-Pujol, J. and Kerbache, L. (2011) ‘Thoughts on kaizen and its evolution Three different perspectives and guiding principles,’International Journal of Lean Six Sigma, 2 (4), 288-308.

- Swinehart, K., Miller, P. and Hiranyavasit C. (2000) ‘World class manufacturing: Strategies for CI’, Business Forum, 25 (1/2), 19–28.

- Trocki, M. (2012), Nowoczesne zarządzanie projektami [Modern Project Management].PWE, Warsaw.

- Turner, R., Ledwith, A. (2018) ‘Project management in small to Medium‐Sized enterprises: Fitting the practices to the needs of the firm to deliver benefit,’ Journal of Small Business Management, 56 (3), 475-493.

- Wyrozębski, P. (2014) Zarządzanie wiedzą projektową [Project Knowledge Management], Difin, Warsaw.

- Zakrzewska-Bielawska, A. (2016)‘Exploration and exploitation paradox: ambidexterity in strategic management,’ Research Papers of Wrocław University of Economics, (420), 435-449.