Introduction

Intelligent systems in production and logistics are increasingly becoming the subject of research on innovative solutions. This is a consequence of the wider and more advanced use of these systems among manufacturing companies around the world. This is due to the fact that systems are becoming more “popular” due to numerous advantages, on the one hand, and, on the other hand, that changes in this regard are increasingly forced by the widely understood environment. This applies to both customers and competitors who directly or indirectly influence the propensity to make necessary modifications to the offered products. The undoubted advantages include: greater production flexibility and easier adaptation to customer requirements, faster deliveries, or an increase in the efficiency and effectiveness of decision-making processes undertaken in enterprises. The most frequently indicated factors influencing the need to make changes in enterprises include: globalization and internationalization of economic entities, which results in greater pressure to customize products, greater increase in their complexity, and their shorter and shorter life cycle. To all this, it should also be added limitations on the side of production factors, especially time – both in the production process and in the delivery of the finished product to the customer. All this “positively” influences the tendency to use new (innovative) solutions both in production and logistics. These solutions are most often referred to as intelligent systems, due to the features and certain properties that boil down to the common denominator, which is the equipment with artificial intelligence. Among these systems can be indicated: Internet of Things (IoT), databases (Data Base), SCADA systems, or SMAC and many others. Their implementation into the economies of many countries around the world is known as digitization. It is becoming an increasingly common phenomenon that often goes beyond the sphere of production (and logistics) and concerns the everyday life of citizens. This means that these systems function parallel to the real world, complementing it in many areas. However, as recent observations show, the “digital world” becomes more real by creating cyber-physical systems, which means that it acquires substitution properties that allow for the replacement of certain selected elements of the surrounding reality in various dimensions. Therefore, it should be emphasized that the development of intelligent systems becomes on the one hand necessary and on the other hand inevitable. This is confirmed by the data according to which in four years the value of the intelligent systems market in the world may reach even USD 11 trillion (McKinsey 2015). The popularity of these systems results mainly from the benefits that enterprises obtain as a result of their use. Some authors most often mention: effective and efficient information management, overcoming “human” inefficiencies in business processes and improving operational activity, reducing costs and minimizing risk (Wronka 2017, p. 109-121). They can relate to different stages of production and logistics and be used with different intensity, i.e., from applications that improve these processes (production and logistics), through complex systems characteristic of “smart factories”, and ending with systems that integrate all the processes of the logistics chain: supply, production or distribution (Wronka, 2017, p. 109-121). In this article, these systems will be referred to as intelligent systems in logistics (ISL) (Wood 2010, p. 7-8).

The above considerations indicate the need to analyze the phenomenon related to the propensity to implement ISL among manufacturing companies in Poland. Hence, the main purpose of this article is to identify the use and assessment of the importance of these systems for the studied entities. Basically, this goal has been divided into two parts – the first one related to the systems most often used by the surveyed companies and the second one related to the research of ISLs that are not too “popular” in terms of use by Polish economic entities. Therefore, it should be emphasized that these two parts are components of the analysis carried out. It consists of two separate articles (written by two authors) with similar titles, with the difference that in one of them is an indication of “most used” and the other “least used” systems. As these two articles (parts) are the constituent elements of the whole, the elements they contain are similar, as they concern the same scientific issues ( they are related to: abstract, introduction and theoretical part). Significant differentiation includes the interpretation of the obtained research results and conclusions drawn from this research.

The implementation of the above purpose was based on obtaining answers to two basic research questions: which of the logistic stages do companies most often use ISL and what is the importance of ISL for the activities of the surveyed companies. This purpose was followed by the structure of this article, which consists of two elements, i.e., the theoretical part and the empirical part. The last one is undoubtedly the added value of this article.

Theoretical background

The subject of this article implies the need to conceptualize the concept of intelligent systems in logistics (ISL). This concept is multidimensional, and on the one hand it includes modern application systems that are part of the logistics chain, and on the other hand, entire chains (all stages) of the logistics process, referred to as integrated logistic chains (ILCh) (Wu 2016, p.396).Therefore, It can be noted that it combines elements related to the concept of Smart Factory and Industry 4.0 in connection with an intelligent supply chain (sales of goods), the functioning of which is based on modern system solutions. The practical application of these solutions is inspired by certain factors, among which the following can be indicated: striving for individualization and complexity of finished products and the need to improve the quality and efficiency of production (delivery) (Ejsmont 2018). These systems (in the production process) are characterized by certain features: flexibility (manifested by universal models, allowing for the creation of smaller batches of goods in accordance with the customer’s specifications and shortening of production cycles); autonomous work (reducing the need for human intervention); diagnostics (contributing to the significant elimination of errors and device failures); increasing adaptability (the use of advanced software enables the process of “learning” machines, which improves their functioning); better communication (data exchange between devices allows the “maintenance department” to be informed about possible problems and thus prevent possible failures) (Fritz 2017). On the other hand, with regard to logistics (in the context of ILCh), the main features are: integration of all processes into one coherent sequence (this allows for combining all logistic stages into one whole); real-time information management (immediate response to changes in sales and supply); flexibility (allows to adapt to the needs of an individual customer); system heterogeneity (allowing for the interaction of various interconnected systems) (Detlor 2010, p.103).

This article distinguishes three such systems: Internet of Things (IoT), cloud computing, Big Data. The first one covers the possibility of making connections (physical or virtual, e.g., via the Internet) of objects (objects) with the use of advanced interoperable technologies (ITU 2006). With regard to ILCh (including production as one of the elements of this chain), IoT can be understood as a concept that includes a network ensuring communication between objects (things) via the Internet in three basic dimensions: available at any time (any TIME), accessible everywhere (any PLACE), and concerning all things – enabling communication on many levels (any THING) (Niyato 2015). This concept was first used by K. Ashton in 1999, when he presented the idea of data transmission using RFID to control the supply chain in the Procter & Gamble corporation. Currently, the use of IoT applies not only to the sphere of production (or logistics), but even to everyday life. It is related to the creation of the so-called “Smart homes” (Lipski 2015, p. 755-766). The efficient operation of IoT depends on the connection of this system with the computing cloud.

Cloud computing means the delivery of computing services over the Internet. It allows access to servers, storage and databases, software and artificial intelligence without having (in the company) the necessary hardware and software (Alijani 2015, p. 35-45). In production and logistics, the most frequently used combination of IoT and cloud computing is: diagnostics of technological machines and production instrumentation, optimization of production volumes, or in the management of logistic supply chains (internal and external transport process) (Lipski 2015, p. 755-766) (Joszczuk-Januszewska 2013, p. 65-76). This solution was defined for the first time in 1996 by S.E. Gillet and M. Kapor, which then came to be seen as an important paradigm in the field of information and communication technologies.

Another system, which is Big Data (BD), is used to collect large volumes of data. Most often it is combined with the two previous solutions. In addition to the typical functions related to data collection, noteworthy is the possibility of examining correlations between data or possibilities in the field of operational management of organizations, where decisions must be made on an ongoing basis in real time. This applies especially to companies with a high complexity of production and logistics processes and a high level of personalization of their products. This system also enables high security of performed operations, due to internal and external threats (Davenport 2012, p. 23-45) (Wieczorkowski 2017, p. 182-196). According to many scientists, Big Data should be analyzed from the point of view of three basic areas: technical, economic and social (Wieczorkowski 2014, p. 182-196).

Methodology

The research was carried out in 2020 on a group of manufacturing companies that used at least one of the following elements in their activities: supply logistics, production, distribution, reverse logistics, or an integrated logistics chain. The survey was conducted throughout the country (16 provinces). They were based on a multi-stage sample selection, which means that it was both purposeful (the first stage of the research) and random (the second stage of the research). During the first stage, 10,000 companies with only manufacturing activities were identified. Then, as a result of the lottery (stage two), a group of 2,500 entities was selected to which the questionnaire was addressed. Feedback was received from 103 economic operators, broken down into different sizes. Of these, 88 were involved in logistics activities (within logistic chains). The study was quantitative and was conducted using the CAWI (Computer-Assisted Web Interview) technique. An original questionnaire with closed-ended questions was used for the study.

When characterizing the research sample, three populations should be taken into account. The first one includes all entities that replied to the research questionnaire addressed to them. The second population consisted of entities that use logistics in at least one of the stages in their activities. The third population concerns enterprises using not only logistics, but also ISL (only 58-65.9% of such entities were recorded in the entire group). The structure of these three populations was quite similar to each other, i.e., in the case of large enterprises it ranged between: 51.5% – 55.2%; secondary: 17.2% – 19.3%; small: 16.5% – 20.7%, micro: 6.8% – 7%. The scope of activities of these entities (using ISL) was mainly global (43.1%).

However, it is necessary to highlight one of the important elements concerning the issue of “methodology” in this article. The analysis was based on structure indicators (percentages), which, according to many scientists, should not be used in the case of a sample of less than 100. However, as the statisticians emphasize, this cannot be considered a factual error, because with a sample of already 50 observations, a percentage may be calculated (Sushani 2016). Hence, the use of this method to interpret the obtained results.

Results and Conclusions

This research focuses on Polish manufacturing companies using ISL at various stages of the logistics chain (supply, production, distribution), reverse logistics, or an integrated supply chain. The importance of these ISLs will be assessed on the basis of structure indicators. It will cover the three (indicated above) main ISLs used by the surveyed entities. The main assumption of this analysis is to answer two fundamental research questions: in which of the logistic stages enterprises most often use ISL and what is the importance of ISL for the activities of the surveyed enterprises. Each of these systems will be analyzed taking into account the size of the entities (large, medium, small, micro), separately for each of the three mentioned systems.

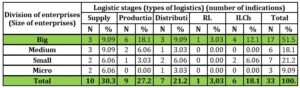

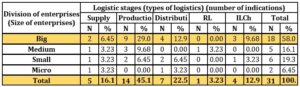

Searching for answers to the first of the above questions, five basic stages (types) of the logistics process were distinguished: supply with material and raw material, production (production, i.e. obtaining a finished product), distribution – relating to the delivery of the final product to recipients (the final element of the logistics chain), which is a combination of all the above three logistic links (integrated logistics chain – ILCh) and reverse logistics, which is a manifestation of ecologistics. The first system (IoT) is given below /tab.1/.

Table 1: Internet of Things (IoT – stages of ISL use in division on enterprise size

Abbreviations: RL – reverse logistics; ILCh – integrated logistics chains

Source: Author’s own elaboration

The above data clearly show a certain regularity: the propensity to use IoT depends on the size of the enterprise. Large entities (51.5%) are the most willing in this respect. They mainly use this system at the production stage. In the logistic context – to a much lesser extent at the stage of supply (9%) and distribution (9%). The share of IoT in this group of enterprises in relation to ILCh is also significant, which proves the perception of the importance of this system in the entire logistics process including all stages. In general terms (for all surveyed entities), this system most often applies to the supply stage (30.3%) and production (27.3%). Of course, the question arises here – what is the reason for this remarkable “popularity” relating to these two specific stages of the logistics process? The answer here can be found in the application (increasingly) of new “just in time 2” solutions, where there is a close relationship between the material supplier and the product manufacturer. Therefore, it can be concluded that IoT undoubtedly supports the implementation of new products in the first stage of the logistics chain and the strengthening of relations between the individual links (entities) of this chain.

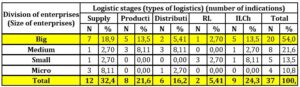

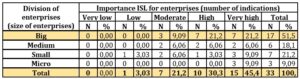

Another analyzed system is Big Data. The presented data indicate that large entities (as in the previous case) are also the most interested in applying this type of solution. It is described in table 2.

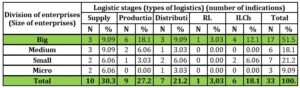

Table 2: Big Data – stages of ISL use in division on enterprise size

Abbreviations: RL – reverse logistics; ILCh – integrated logistics chains

Source: Author’s own elaboration

Among these entities, the use of Big Data applies mainly to the supply stage (32.4%) and production (21.6%). Therefore, the situation is very similar to that of IoT. This is undoubtedly the result of linking the two systems together. This means that Big Data complements IoT – it can be said that they are complementary to each other. In this context, Polish entities use them in their business activities. Another important fact proves the complementary character of this system. As in IoT, the connection of the two stages is visible: supply and production. Therefore, it can be concluded that Big Data is used in the implementation of “just in time” and “just in time 2” solutions. While IoT undoubtedly creates and tightens relations between entities (links) of the logistics process, this system is a data buffer that allows these relations to be made real.

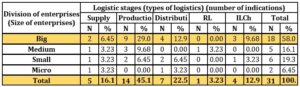

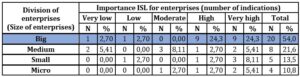

The next system analyzed in this article is cloud computing. Also, this solution “applies” to the greatest extent to large enterprises (58% of the surveyed) /tab. 3/.

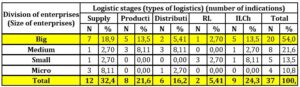

Table 3: Cloud computing – stages of ISL use in division on enterprise size

Abbreviations: RL – reverse logistics; ILCh – integrated logistics chains

Source: Author’s own elaboration

Among this group of enterprises, the main stage in which this system is used is production (45.1%) and distribution (22.6%), which significantly distinguishes it from the previous two systems. This undoubtedly proves that cloud computing is treated by Polish enterprises as a completely independent system. The fact that this system is definitely “related” to the production stage confirms its specificity, which is the greatest usefulness at this stage of the logistics process. This may mean that the use of this system serves such purposes as: diagnostics of technological machines, product quality control systems, etc. The significant level of use of this system in distribution indicates that it relates mainly to the management of customer data and final recipients of finished products. This may prove that the previous two systems are “sufficient” to support the procurement stage. On the other hand, the specificity of this system (its completely independent character) indicates the need for a greater connection of “production” and “distribution” with each other owing to the use of this system.

Summing up, the above analysis allows to obtain answers to the first of the presented research questions. Generally, it turns out to be system dependent. However, the most frequently indicated stage of ISL use is the production stage (production logistics). This may result directly from the fact that production is the most “common” and “demanding” stage among all stages of an integrated logistics chain. In practice, this means the necessity to engage enormous intangible material resources, which can be optimized thanks to the use of ISL (and this is also the case). These systems are also used (to a lesser extent) directly in the supply and distribution processes. Two of them (IoT and Big Data), due to their specificity (the possibility of linking suppliers with the production process), relate mainly to procurement. Only cloud computing is used by Polish enterprises as the main instrument of cooperation with recipients of finished (final) products. It is worth noting that among the best-known ISLs, the inclination to use these systems mostly applies to large entities, which are characterized by the greatest resources in this respect. The remaining groups use these systems at marginal degree of logistics processes stages.

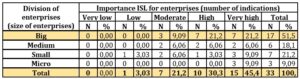

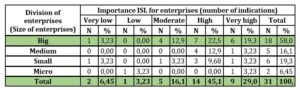

Another task carried out as a part of this article is to obtain answers to the second of the research questions. This task was performed on the basis of the analysis of the structure indices presenting the obtained results of the conducted research. As in the case of the previous research question, here too, each of the systems was separately assessed. The first is IoT, the “popularity” of which is one of the largest among Polish economic organizations. The data show that 33 out of 58 companies (56.9%) use the IoT in integrated logistics chains. In practice, this means that every second enterprise is able to express its opinion on the usefulness of this system /tab. 4/

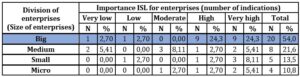

Table 4: Internet of Things (IoT) – importance of ISL in division on enterprise size

Source: Author’s own elaboration

The data included in the table above prove that the IoT system is very usefully assessed by Polish enterprises. This is evidenced by the fact that neither of them pointed to the “very small” importance of this system. Also, in the case of “low” importance, the number of indications is practically zero (only 1 entity assessed the significance of this system). It is worth paying attention to the fact that large enterprises assess the significance of this system best. Moreover, a certain regularity can be noticed here: in general, with the increasing importance of this system, the number of entities pointing to its practical significance increases. Therefore, when answering the research question, it should be emphasized, firstly, that IoT is positively assessed by the surveyed entities and, secondly, that its importance for the surveyed companies is very high (15 entities indicate this type of importance (over 45% of the overall level of Hence, in the opinion of the respondents, this system is extremely useful in the logistics chain (both in production and distribution). This high level of satisfaction is undoubtedly the result of its “universal” character, i.e., enabling its use at various stages of the widely understood production process. Such a positive assessment of the system will undoubtedly influence its more and more common use among Polish manufacturing companies in the future. The only serious barrier may be the shortages of the company’s resources – both tangible and intangible. Hence, (in the Polish economic realities) the implementation of this solution may be spread over time.

Another system in the group of the most “popular” in Poland is Big Data. The popularity of this system is much greater than even in the case of the previous one, i.e., IoT. As many as 37 entities indicated the use of this system in their business activities (63.8%), which in practice means that definitely more than half of the respondents were able to assess its usefulness / tab.5/.

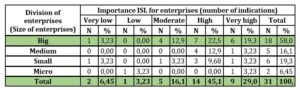

Table 5: Big Data – importance of ISL in division on enterprise size

Source: Author’s own elaboration

The situation with this system is similar to that with IoT. As the importance grows, so does the number of entities assessing it in an increasingly positive way. For the “moderate” rating, only 4 (10.8%) entities indicated the importance of this system (including none of the large entities), where in the case of the “very large” rating, as many as 16 companies (43.2%) confirmed the importance of the system in their business activities. The only significant difference (compared to IoT) consists in small indications concerning “very small” (3 examined entities) and “small” (2 examined entities) importance of this system for the analyzed entities. Generally – these assessments concern large entities to the greatest extent, which proves that this system is “popular” among this group of enterprises. This result confirms the usefulness of Big Data among Polish economic organizations. This is probably the result of the complementary nature of this system in relation to IoT. Therefore, answering the research question posed, it should be stated that the significance of this system in the current economic realities (relatively low level of implementation of the assumptions resulting from Industry 4.0 in Poland) is very high. It is a pity that the knowledge and practical application of these two systems among manufacturing companies is marginal.

Cloud computing is the third of the most “popular” systems in Poland. With regard to this system, it can be stated that the situation is slightly more different than in the case of the previous two analyzed systems. Despite the fact that the number of enterprises declaring the use of cloud computing is over 31 (out of 58), definitely fewer of them indicate the importance of “very high” (only 9 surveyed entities) (29%) /tab. 6/.

Table 6: Cloud computing – importance of ISL in division on enterprise size

Source: Author’s own elaboration

The above data indicate that the highest number of positive evaluations concerns the meaning of “high” (45% of respondents). The “very small” and “small” categories are in a definite minority (the number of indications varies around 1-2), which proves that this system is highly rated by manufacturing companies. However, comparing it with the two systems above, it can be concluded that the significance rating is slightly lower. This is probably the effect of less interference of this system in the process of direct “handling” of individual logistic stages. As previously indicated, cloud computing is focused on collecting and processing data necessary to make accurate and immediate decisions. Nevertheless, answering the research question posed, it should be stated that in general terms the significance of this system is positively assessed at a high level.

To sum up, the above systems are characterized by a different level of interest among the surveyed enterprises in Poland. Their common feature is that they are mainly used by the largest economic entities. This is due to the fact that this type of enterprise is “equipped” with relatively large material and non-material resources, which allows for easier implementation of new solutions from the environment. Hence, the assessment of these systems is carried out mainly from their point of view. Answering the second research question (regarding the significance level of these systems), it can be said that they are assessed extremely positively. All assessments relate to the category of “high” or “very high” importance, which clearly proves the role they play in logistics processes among the surveyed companies.

Conclusions

The above analysis allowed to obtain answers to two key research questions, as a result of which several important conclusions were drawn. First, intelligent systems play a significant role in broadly understood logistics processes, including production, delivery and distribution. This is indicated by a number of properties that they are characterized by. Second, there are many ISL solutions used in practice, and to a large extent their selection depends on the necessity to adjust these systems to the individual needs of enterprises. Third, in their case we can talk about their different level of “popularity”, which is determined by many factors, including the resources of individual organizations, the tendency to implement innovative solutions, or the availability of these systems in Poland. Fourth, regardless of the “level of popularity”, it can be stated that generally the systems in the group of “most used” in Poland refer to all three stages of the logistics process. Large entities dominate in the use of ISL at individual stages of logistics – the share of small and micro entities is negligible (you can even say that it is even zero). The above conclusions made it possible to answer the first research question concerning the use of ISL at particular stages of the logistics chain. Fifth, the obtained conclusions were the basis for the answer to the second research question concerning the assessment of the importance of these particular systems. It turns out that the evaluation of all presented systems is good or very good. This proves their great importance and an extremely positive assessment by the surveyed companies. The obtained answers to the research questions are extremely important as they allow identifying the significance of these systems and ascertaining the prospects of their development in the next few years. Sixth, the complementary nature of some of the systems under discussion can be seen. In practice, this means that they should be implemented comprehensively. The use of only one of them may not contribute to the improvement of the efficiency of production companies to the extent that would meet the expectations of implementing entities. Therefore, this should be taken into account and this type of indication should be treated as a practical recommendation. This is undoubtedly an added value resulting from the research conducted and described in this article.

(adsbygoogle = window.adsbygoogle || []).push({});

References

- Alijani, G. S., Fulk, H. K., Omar, A. and Tulsi, R. (2015), ‘Cloud computing effects on small business,’ Entrepreneurial Executive, 19, 35–45.

- Davenport, T., Barth, P., Bean, R. (2012), ‘How ‘Big Data’ is different,’ MIT Sloan Management Review, 54(1), 23-45.

- Detlor, B. (2010), ‘Information Management,’ International Journal of Information Management, 30, 103.

- Ejsmont, K. (2018), ‘Inteligentne technologie – pomiar i ocena wymiaru społecznego, ‘ {Online] [23 November 2018] http://www.ptzp.org.pl/files/konferencje/kzz/artyk_pdf_2018/T2/2018_t2_409.pdf

- Fritz, C.(2017), ‘Inteligentne maszyny: Adaptacja architektur systemów sterowania,’ Control Engineering, 4.

- ITU (2006), Overview of the Internet of Things, Telecommunication Standardization Sector of ITU, International Telecommunication Union, Switzerland 2006.

- Joszczuk-Januszewska, J.(2013), ‘Aspekty ochrony środowiska naturalnego w obszarze chmury obliczeniowej, ‘ Zeszyty naukowe wydziału informatycznych technik zarządzania wyższej szkoły informatyki stosowanej i zarządzania, Warszawa, 65–76.

- Lipski, J. (2015), Internet rzeczy w zastosowaniu do sterowania produkcją, Knosala R. (ed.) Innowacje w zarządzaniu i inżynierii produkcji, t. 2, Polskie Towarzystwo Zrządzania Produkcją, Opole, 755-766.

- McKinsey Global Institute (2015), ‘The Internet of Things: Mapping the Value beyond the Hype, ‘ Executive summary, Report,.

- Niyato, D., Lu, X., Wang, P., Kim, D.I. and Han, Z.(2015), ‘Economics of Internet of Things (IoT): An Information Market Approach, ‘ IEEE Wireless Communications, 23(4).

- Sushani, G.; Proportions, Percentages and Ratios | Data Analysis | Social Research, Sociology discussion, [Online], [access: 15 May 2016] https://www.sociologydiscussion.com/social-research-2/proportions-percentages-and-ratios-data-analysis-social-research/13383

- Wieczorkowski, J.and Jurczyk-Bunkowska, M.(2017), Big data jako źródło innowacji w zarządzaniu i inżynierii produkcji, Knosala R. [ed.), Innowacje w zarządzaniu i inżynierii produkcji, t. 1, Oficyna Wydawnicza Polskiego Towarzystwa Zarządzania Produkcją: Opole.

- Wieczorkowski, J and Polak, P. (2014), ‘Big data: Three-aspect approach, ‘ Online Journal of Applied Knowledge Management, International Institute for Applied Knowledge Management, 2(2), 182-196.

- Wood, R.(2010), ‘Creating The Smart Supply Chain, ‘ MHD Supply Chain Solutions, 2010, 7-8.

- Wronka, A.(2017), ‘Inteligentne łańcuchy dostaw, Studia Ekonomiczne, ‘ Zeszyty Naukowe Uniwersytetu Ekonomicznego w Katowicach, Katowice, 337, 109-121.

- Wu, L., Yue X., Jin, A.and Yen, D.C. (2016), ‘Smart Supply Chain Management: A Review and Implications for Future Research, ‘ The International Journal of Logistics Management, 27, 396.