Introduction

The world’s ever-increasing use of plastics has created large amount of small plastic particles that are circulating in the environment. Over the time, plastic particles are fragmenting into smaller and smaller ones and eventually become microplastics and even nanopalstics. The concern for the environment and the possible negative impact of microplastics on the human health formed the basis for the conducted research. The main goal of the study was to answer the following question: How are food processing companies dealing with the microplastic risk in their processes? That perspective formed the global trends which are now discussed with the operational level of organizations and functioning management practices such as risk assessment within the food safety obligations.

Literature Review

Microplastic in food

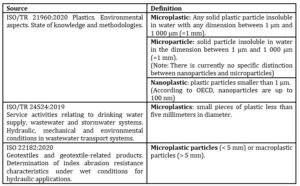

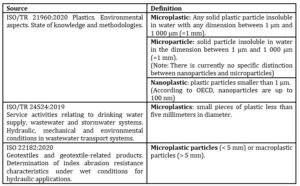

There is no internationally recognised definition of microplastics; however, depending on the source of publications, different definitions are adopted. Table 1 presents some definitions used in ISO documents.

Table 1: Selected definitions of microplastic in international standards

Source: based on ISO Online Browsing Platform (OBP)

Source: based on ISO Online Browsing Platform (OBP)

A distinction can be made between primary and secondary microplastics. Primary microplastics are plastics that were originally manufactured to be that size, while secondary microplastics originate from the fragmentation of larger items (EFSA CONTAM Panel, 2016).

Microplastics are likely to originate from other sources than the food itself, e.g. processing aids, water, air or being release from machinery, equipment and textiles, although there is no available literature on this issue. It is therefore possible that the amount of microplastics increases during processing. The effectof other processes, e.g. cooking and baking, on the content of plastics is not known Microplastics are likely to originate from other sources than the food itself, e.g. processing aids, water, air or being released from machinery, equipment and textiles (EFSA CONTAM Panel, 2016). Polymers used in food packaging materials are the source of food contamination. The general rule is that smaller sized additives migrate faster and at higher rates than those of larger sizes (Hardy et al., 2018). It is therefore possible that the amount of microplastics increases during processing. The effect of other processes, e.g. cooking and baking, on the content of plastics is also not known (EFSA CONTAM Panel, 2016).

Microplastics can contain on average 4% of additives and the plastics can adsorb contaminants.

Both additives and contaminants can be of orga nic as well of inorganic nature and they can be Microplastics can contain, on average, 4% of additives, and the plastics can absorb contaminants (EFSA CONTAM Panel, 2016). Both additives and contaminants can be of organic as well as inorganic nature and they can be risky for the human health. Unfortunately, the impact of the microplastic on the human health is not well recognized. Examples of research on this issue can be found in the studies of Smith et al. (2018), Deng, Zhang, Lemos & Ren (2017) and Lu et al. (2016).

In the food industry, high hopes are put on the nanotechnology and nanomaterials that entered the packaging market, mainly nanocomposites. However, new packaging materials based on nanocomposites are bringing potentially new problems for recycling. Until now, there is no real industrial method of recycling packaging nanobiocomposites (Foltynowicz, 2020b).

European Green Deal and microplastic

The European Green Deal is a response to the observed global warming and climate changes. It is a growth strategy that aims to transform the EU into a fair and prosperous society, with a modern, resource efficient as well as competitive economy. There should be no net emissions of greenhouse gases, and economic growth is decoupled from resource use (EU, 2019a). Two elements of the Green Deal, described in (EU, 2019a), are essential for the problem of microplastic in food. The first one is circular economy and the second one is environmentally friendly food system.

The circular economy is a business system which replaces the concept of “end-of-life”. In essence, it aims to maximize the use of renewable energy sources, and eliminate the use of toxic chemicals that prevent reuse as secondary raw materials (Nowicki et al., 2020). Reducing plastics use and increasing plastic materials reuse are the goals that can lead to the reduction of microplastics that are being introduced to the environment and consequently to the food itself.

As for the points of the European Strategy for Plastics, in a Circular Economy strategy, many of them concern packaging directly. One of the strategy’s goals is to ensure that all plastic packaging will be recyclable and that 55% of the recycling of plastic packaging wastes will be achieved by 2030 (EU, no date). Some other legal requirements in that field are already established – such as the (EU) 2019/904 directive where one of the regulations forces producers to use recycled polyester (r-PET) materials in which at least 25% of the products are from recycled materials. That goal should be obtained by 2025 (EU, 2019b). The other actions are still in progress. For example, the ECHA’s (European Chemicals Agency) proposal aims to ban products from the European market that contain intentionally added microplastics if these are released to the environment when the products are used. Examples of these actions are cosmetics, cleaning and laundry products, fertilisers, plant protection products and seed coatings. Advanced work is being carried out to prevent the release of microplastic infill material from artificial turf sports pitches. The restriction, according to ECHA, will prevent 500 000 tonnes of microplastics from ending up in the environment over 20 years. Over the same period, the total cost of the restriction to the European society is estimated to be €10.8 or €19.1 billion (ECHA, 2021).

The implementation of The Green Deal strategy was unexpectedly interrupted by the outbreak of the coronavirus pandemic and the following lockdown which has a significant impact on the global economy, leading to a crisis (Foltynowicz, 2020a).

Organic farming products

According to the EU Common Agricultural Policy, objectives such as: fostering the competitiveness of agriculture; ensuring the sustainable management of natural resources, and climate action; as well as achieving a balanced territorial development of rural economies and communities including the creation and maintenance of employment shall be achieved (EU, 2013). Organic farming production is considered as one of the methods supported to achieve the goal of producing high quality food products. Under the current EU law, the basic document containing the requirements for organic production is Council Regulation (EC) No 848/2018 of The European Parliament and of The Council of 30 May 2018 on organic production and labeling of organic products and repealing Council Regulation (EC) No 834/2007 and the regulations implementing this regulation. The regulation will be fully introduced starting 2022. The production of organic foods is environmentally friendly; it does not utilize antibiotics, growth hormones, pesticides, chemical fertilizers or growth regulators. Organic foods are often regarded as more friendly to the environmental agriculture and, ultimately, healthier than conventional, non-organic foods (Lee, Fu and Chen, 2019; Kafel, Nowicki and Wojnarowska, 2021).

Organic production covers all stages of production, preparation and distribution with specific requirements for the agricultural activities, the processing of organic food, and the processing of organic feed.

The specific principles applicable to the processing of organic food are (EU, 2018):

– The production of organic food from organic agricultural ingredients,

– The restriction of the use of food additives and non-organic ingredients as well as micronutrients and processing aids except for technological and sensory functions, , so that they are used to a minimum extent and only in cases of essential technological needs or for nutritional purposes,

– The exclusion of substances and processing methods that might be misleading regarding the true nature of the product,

– The processing of organic food with care, preferably using biological, mechanical and physical methods,

– The exclusion of food that contain, or consist of engineered nanomaterials.

Unlike the previous organic products regulation (834/2007), the production of engineered nanomaterials is prohibited. Engineered nanomaterials, in the context of organic farming, are defined as: any intentionally produced material that has one or more dimensions of the order of 100 nm or less, or that is composed of discrete functional parts, either internally or at the surface, many of which have one or more dimensions of the order of 100 nm or less, including structures, agglomerates or aggregates, which may have a size above the order of 100 nm but retain properties that are characteristic of the nanoscale (EU, 2015). However, there is still no direct reference to the unintended use of nanomaterials in organic food, which also applies to the contamination of microplastics.

Despite very strict regulations related to the processing of organic food, there are no additional requirements related to their packaging and package materials. Producers are required to meet the same requirements as for other food products. The organic food quality scheme promotes natural balance, with environmentally friendly production and packaging. It positively affects the consumers’ buying behaviour (Onwezen, 2015; Chrysochou and Festila, 2019). Producers usually try to emphasize the ecological character of the product by using packaging materials and design that has positive associations with customers. However, these are voluntary activities that are not covered by the organic food regulations and certification system (Kafel, Nowicki and Wojnarowska, 2021).

Methods

The purpose of the study was to investigate, how the studied companies that are under the strict obligatory surveillance according to the organic food production rules, sell high quality products and deal with microplastic risk in their processes. The online survey was carried out in September 2020 (Kafel, Nowicki and Wojnarowska, 2021). From the population of polish organic farming producers (food processors), 300 records were randomly chosen and an online survey was carried out. The questionnaire was sent to top managers responsible for quality and food safety systems in organizations. 46 valid questionnaires were obtained, representing 15,3 percent respond rate. The size of the general population of organic processing companies in Poland in 2018 was 910, and at the end of 2019, was 1022 (IJHARiS, 2021).

The data were analysed with the use of TIBCO Statistica 13.3 software. Within the analysis, the following methods were used: the exploratory phase of data analysis, Descriptive Statistics, selected t-tests with the comparisons of means and measures of variation in the two groups visualized in box and whisker plots.

Results and Discussion

Organization’s details and implemented standardized management systems

All of the studied companies employed less than 250 employees. There were 17 organizations which employed from 2 to 10 people, 18 that employed between 11 and 50 people, and 11 organizations that employed between 51 and 250 employees.

Two studied companies referred to local and regional markets as the main scope of their products. The remaining companies, 24 and 20 organizations, referred to domestic and international markets as the range of their activities, respectively.

All the studied companies have implemented the organic farming requirements according to Council Regulation (EC) 834/2007 which is now in the transition period to the EU Regulation 848/2018 and obligatory food safety system – HACCP. Within the studied companies, the following voluntary management standards were implemented: ISO 9001 (10), ISO 14001 (9), ISO 22000 (7), PN-N 18001/OHSAS 18001/ISO 45001 (5), IFS Food (6), and BRC Food (6). According to the presented data, most of the studied companies implemented standards that are typically implemented in the food sector (Kafel and Casadesus, 2016; The ISO Survey, 2020; Kafel, Nowicki and Wojnarowska, 2021).

Microplastic Risks

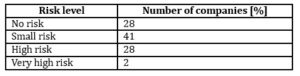

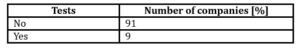

Companies under study were asked to assess the overall product safety related to microplastics hazard in their organic products. As indicated in table 1, most of the companies consider the risk of microplastics to be negligible. Only 2% of the respondents indicated a very high risk

Table 1: Overall product safety related to microplastics hazard

According to the HACCP rules, risk assessment is the first step in the process of implementing the food safety system. All risks at all stages of production should be identified and assessed to identify the critical control points. None of the surveyed organizations identified critical control points directly related to the presence of microplastics in products. The number of identified critical control points should be small; therefore, the analysed microplastics hazard was not indicated. However, that result does not mean that it was not considered at the risk analysis stage. In 13% of the studied organizations, that risk was included in the risk assessment. The other 87% did not include microplastics as a separate hazard in their food safety system.

Considering the results presented in table 1 and the number of organizations that indicated the hazard of microplastics in the risk analysis, one can get the impression of inconsistency. It could be explained by the fact that some of the organizations used, in the risk matrix, the general hazard groups, such as “physical hazards in the product”. That group also contains the risks of microplastics, but it is not considered to be important to be assessed separately.

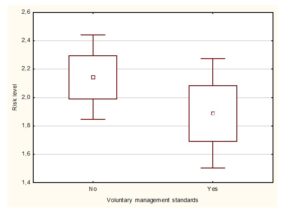

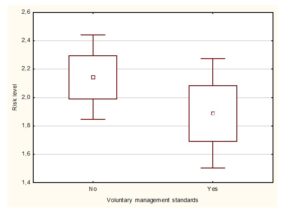

The studied organizations were divided into two groups of companies; with and without implemented and certified voluntary management systems. A comparison of the risk assessment of microplastics for those groups is shown on figure 1.

Figure 1: Voluntary management systems vs. risk level

The risk level for the data presented on figure 1 was calculated as follows: no risk – value 1, small risk – value 2, high risk – value 3 and very high risk – value 4. Microplastic risk was assessed higher by the group of organizations that do not have voluntary management systems implemented. Organizations that have voluntary management systems implemented assess the risk of microplastic as lower. The observed differences between the study groups are small and do not indicate a statistically significant difference for p value = 0.05.

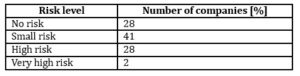

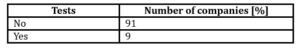

Table 2: Laboratory tests detecting the presence of microplastics in organic products

According to ECHA, there are no reliable and accessible test methods to detect microplastic particles in food (ECHA, 2021). The results presented in table 2 confirm that there is a little interest in testing products for detecting microplastic contamination of food. As some of the studied representatives stated, there are required and documented laboratory test reports for packaging materials (global and specific migration); however, the precision of the methods performed does not allow to detect the presence of very small particles, such as microplastic ones.

Supply chain feedback

Nowadays, food industry producers operate in an organized food chain. Between the farmer and the consumer, there are usually such organizations as: producers, logistic operators as well as retailers. All of them can be the source of the feedback concerning microplastic risk. As indicated by Yontar and Ersöz research (2020), the resolution of customer complaints is highly correlated with customer satisfaction.

On the other hand, complaints related to microplastic hazards should be treated by producers as unjustified. That type of complaints is also discussed in literature and there are some examples of customers that are making inauthentic complaints on a regular basis (Reynolds and Harris, 2005). That was the reason to check with the studied companies if they receive inquiries or complaints regarding the presence of microplastics in food products.

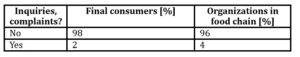

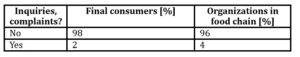

Table 3: Inquiries or complaints regarding the presence of microplastics in food products

As shown in table 3, both for final food consumers and the organizations in the food chain, the feedback related to microplastic risk is inconsiderable. Only in 2% of the studied organizations, that interest was formally directed by final consumers. The interest measured by inquires or complains from other organizations in the food chain concerning microplastic, was documented only in 4% of the studied food producers.

Conclusions

From the results obtained within the study, it can be concluded that microplastic risk in organic products is a new issue that is still not very well recognised. The overall risk for food safety was estimated by producers as rather low. Only 30% of the respondents indicated a high or very high risk. That kind of risk level has been associated with different voluntary management systems implemented in the studied companies. There were no significant differences in the perception of microplastics hazards between the group of companies with implemented and certified management systems and the group that did not implement such standards.

The interest of consumers and other organizations if food chain with the microplastic was quite small. The changes that are planned by governments and other authorities such as the circular economy strategy or the EU plastic strategy are still at a general/national level and have not yet been fully operationalized by food companies.

Acknowledgement

The Project has been financed by the Ministry of Science and Higher Education within the “Regional Initiative of Excellence” Programme for 2019-2022. Project no.: 021/RID/2018/19. Total financing: 11 897 131,40 PLN.

References

- Chrysochou, P. and Festila, A. (2019) ‘A content analysis of organic product package designs’, Journal of Consumer Marketing, 36(4), pp. 441–448. doi: 10.1108/JCM-06-2018-2720.

- Deng, Y. et al. (2017) ‘Tissue accumulation of microplastics in mice and biomarker responses suggest widespread health risks of exposure’, Scientific Reports, 7(1), p. 46687. doi: 10.1038/srep46687.

- ECHA (2021) Scientific committees: EU-wide restriction best way to reduce microplastic pollution. Available at: https://echa.europa.eu/pl/-/scientific-committees-eu-wide-restriction-best-way-to-reduce-microplastic-pollution.

- EFSA CONTAM Panel (2016) ‘Presence of microplastics and nanoplastics in food, with particular focus on seafood’, EFSA Journal, 14(6). doi: 10.2903/j.efsa.2016.4501.

- EU (2013) ‘Regulation (EU) No 1305/2013 of the European Parliament and of the Council of 17 December 2013 on support for rural development by the European Agricultural Fund for Rural Development (EAFRD) and repealing Council Regulation (EC) No 1698/2005’.

- EU (2015) ‘Regulation (EU) 2015/2283 of the European Parliament and of the Council of 25 November 2015 on novel foods, amending Regulation (EU) No 1169/2011 of the European Parliament and of the Council and repealing Regulation (EC) No 258/97 of the European Parliam’.

- EU (2018) ‘Regulation (EU) 2018/848 of The European Parliament and of the Council of 30 May 2018 on organic production and labelling of organic products and repealing Council Regulation (EC) No 834/2007’.

- EU (2019a) ‘Communication from the Commission to the European Parliament, the European Council, the Council, the European economic and social committee and the committee of the regions. The European Green Deal’. Brussels, COM(2019) 640 final.

- EU (2019b) Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment, Plasticseurope.De. Available at: https://www.plasticseurope.org/en/resources/publications/1689-working-together-towards-more-sustainable-plastics%0Ahttps://www.plasticseurope.org/en/resources/publications%0Ahttps://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0904&from=EN.

- EU (no date) A European strategy for plastics in a circular economy. Available at: https://ec.europa.eu/commission/sites/beta-political/files/plastics-factsheet-challenges-opportunities_en.pdf (Accessed: 20 January 2021).

- Foltynowicz, Z. (2020a) ‘New European Union Green Deal in tough times of covid-19 Plague’, in R. Pamfilie, V. Dinu, L. Tăchiciu, D. Pleșea, C. V. (ed.) 6th BASIQ International Conference on New Trends in Sustainable Business and Consumption. Messina.

- Foltynowicz, Z. (2020b) ‘Polymer packaging materials – friend or foe of the Circular Economy’, Polimery, 65(01), pp. 3–7. doi: 10.14314/polimery.2020.1.1.

- Hardy, A. et al. (2018) ‘Guidance on risk assessment of the application of nanoscience and nanotechnologies in the food and feed chain: Part 1, human and animal health’, EFSA Journal, 16(7). doi: 10.2903/j.efsa.2018.5327.

- IJHARiS (2021) ‘https://www.gov.pl/web/ijhars/dane-o-rolnictwie-ekologicznym’.

- Kafel, P. and Casadesus, M. (2016) ‘The order and level of management standards implementation: Changes during the time’, TQM Journal, 28(4). doi: 10.1108/TQM-02-2015-0027.

- Kafel, P., Nowicki, P. and Wojnarowska, M. (2021) ‘Packaging’s of the organic farming products in the context of circular economy’, SHS Web of Conferences. Edited by T. Kliestik, 92, p. 05011. doi: 10.1051/shsconf/20219205011.

- Lee, T. H., Fu, C.-J. and Chen, Y. Y. (2019) ‘Trust factors for organic foods: consumer buying behavior’, British Food Journal, 122(2), pp. 414–431. doi: 10.1108/BFJ-03-2019-0195.

- Lu, Y. et al. (2016) ‘Uptake and Accumulation of Polystyrene Microplastics in Zebrafish ( Danio rerio ) and Toxic Effects in Liver’, Environmental Science & Technology, 50(7), pp. 4054–4060. doi: 10.1021/acs.est.6b00183.

- Nowicki, P. et al. (2020) ‘Circular economy’s standardized management systems. Choosing the best practice. Evidence from Poland’, International Journal for Quality Research, 14(4), pp. 1115–1128. doi: 10.24874/IJQR14.04-08.

- Onwezen, M. C. (2015) ‘I did good, and we did bad: The impact of collective versus private emotions on pro-environmental food consumption’, Food Research International, 76, pp. 261–268. doi: 10.1016/j.foodres.2015.03.032.

- Reynolds, K. L. and Harris, L. C. (2005) ‘When service failure is not service failure: an exploration of the forms and motives of “illegitimate” customer complaining’, Journal of Services Marketing. Edited by S. Baron, 19(5), pp. 321–335. doi: 10.1108/08876040510609934.

- Smith, M. et al. (2018) ‘Microplastics in Seafood and the Implications for Human Health’, Current Environmental Health Reports, 5(3), pp. 375–386. doi: 10.1007/s40572-018-0206-z.

- The ISO Survey (2020) The ISO Survey of Management System Standard Certifications 2018, ISO.

- Yontar, E. and Ersöz, S. (2020) ‘Investigation of Food Supply Chain Sustainability Performance for Turkey’s Food Sector’, Frontiers in Sustainable Food Systems, 4. doi: 10.3389/fsufs.2020.00068